loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ජන. . 20, 2025 14:55

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

In the ever-evolving world of industrial equipment, the fiberglass-reinforced plastic (FRP) vessel, particularly the 24 x 72 size, has emerged as a cornerstone for various applications. Navigating through the complex choices of industrial vessels demands not only expertise but also a keen understanding of material science and industry requirements.

Professional endorsements from industry authorities underscore the credibility of FRP vessels. Industry leaders and materials scientists consistently publish studies verifying the exceptional corrosion resistance and thermal insulation properties of fiberglass-reinforced plastics. Such authoritative insights not only cement the vessel’s standing in industrial applications but also inspire trust among potential adopters debating the transition from traditional materials. Trustworthiness in the sourcing of these FRP vessels is another critical consideration. Manufacturers with ISO certifications often guarantee that their products have passed rigorous quality control standards, instilling confidence in buyers. Furthermore, many reputable manufacturers offer extensive warranties and provide comprehensive after-sale support, ensuring that clients feel supported throughout the lifecycle of the vessel. Plant operators considering a switch to the 24 x 72 FRP vessel should conduct thorough assessments of their specific requirements and environmental conditions. Partnering with specialized engineering consultants can elucidate the long-term benefits and integration strategies tailored to optimize performance and cost-efficiency. These professionals bring a wealth of knowledge, backed by substantive case studies and field research, providing a data-driven foundation for decision-making. In conclusion, the 24 x 72 FRP vessel exemplifies innovation in industrial vessel technology. Its establishment as a reliable, adaptable, and economical option is not merely serendipitous but a reflection of continuous advancements and validations from field experts. As industries evolve, embracing such strategic assets will be crucial in maintaining competitiveness and operational efficacy. The integration of FRP vessels signifies a forward-thinking approach, marrying durability with flexibility to meet the dynamic demands of modern industry challenges.

Professional endorsements from industry authorities underscore the credibility of FRP vessels. Industry leaders and materials scientists consistently publish studies verifying the exceptional corrosion resistance and thermal insulation properties of fiberglass-reinforced plastics. Such authoritative insights not only cement the vessel’s standing in industrial applications but also inspire trust among potential adopters debating the transition from traditional materials. Trustworthiness in the sourcing of these FRP vessels is another critical consideration. Manufacturers with ISO certifications often guarantee that their products have passed rigorous quality control standards, instilling confidence in buyers. Furthermore, many reputable manufacturers offer extensive warranties and provide comprehensive after-sale support, ensuring that clients feel supported throughout the lifecycle of the vessel. Plant operators considering a switch to the 24 x 72 FRP vessel should conduct thorough assessments of their specific requirements and environmental conditions. Partnering with specialized engineering consultants can elucidate the long-term benefits and integration strategies tailored to optimize performance and cost-efficiency. These professionals bring a wealth of knowledge, backed by substantive case studies and field research, providing a data-driven foundation for decision-making. In conclusion, the 24 x 72 FRP vessel exemplifies innovation in industrial vessel technology. Its establishment as a reliable, adaptable, and economical option is not merely serendipitous but a reflection of continuous advancements and validations from field experts. As industries evolve, embracing such strategic assets will be crucial in maintaining competitiveness and operational efficacy. The integration of FRP vessels signifies a forward-thinking approach, marrying durability with flexibility to meet the dynamic demands of modern industry challenges.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

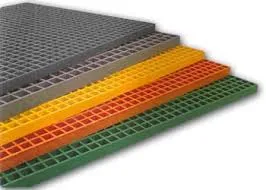

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025