loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Need covered grating with anti-slip corrosion-resistant FRP?

covered grating, grating cover, frp grating manufacturer are essential solutions in the manufacturing industry, specifically within Manufacturing of building materials and other building components and Manufacturing of non-metallic structural components for construction. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product category is an ideal choice for businesses in these sectors.

Table of Contents

- covered grating, grating cover, frp grating manufacturer Overview

- Benefits & Use Cases of covered grating, grating cover, frp grating manufacturer in Manufacturing of non-metallic structural components for construction

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on covered grating, grating cover, frp grating manufacturer from Zhaojia Composites Co., Ltd

covered grating, grating cover, frp grating manufacturer Overview

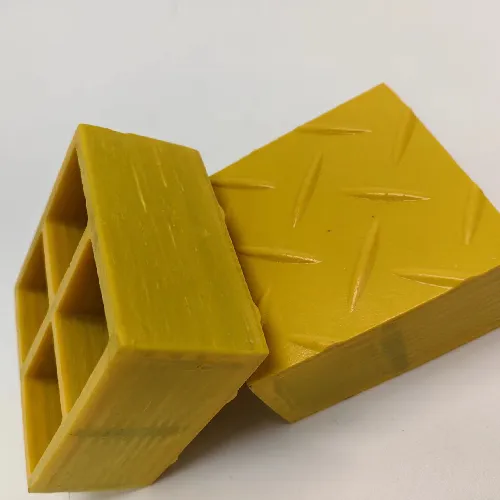

Covered grating—also called a grating cover or plate-top FRP grating—is a fiberglass reinforced plastic (FRP/GRP) panel that combines an open grating with a solid, anti-slip cover plate. For B2B decision makers in building materials manufacturing and non-metallic structural components, covered grating solves two problems at once: it delivers high load-bearing capability while preventing spills, splash, odor transmission, and small-part drop-through. Typical configurations include overall thicknesses of 25–50 mm, cover layers of 3–5 mm with embedded quartz grit, and standard meshes such as 38 × 38 mm. Common panel sizes include up to 1,220 × 3,660 mm, with resin systems (orthophthalic, isophthalic, or vinyl ester), UV inhibitors, and fire-retardant options available to meet safety and compliance requirements.

Zhaojia Composites Co., Ltd is a trusted FRP grating manufacturer serving global industrial clients with molded and pultruded platforms, trench covers, and walkways. Precision cutting, sealed edges, color coding, and custom load/span designs help engineering teams integrate covered grating into platforms, mezzanines, and process areas with fewer trade-offs. In projects where steel grating has struggled with corrosion and frequent repainting, FRP covered grating typically offers a longer, more predictable service life and consistent slip resistance—especially in wet or chemically aggressive environments.

Benefits & Use Cases of covered grating, grating cover, frp grating manufacturer in Manufacturing of non-metallic structural components for construction

In the Manufacturing of non-metallic structural components for construction, covered grating is a versatile choice for production floors, chemical dosing areas, mezzanines, cable trenches, sumps, and inspection platforms. The solid grating cover helps contain debris and fluids while improving underfoot comfort and noise dampening. Its non-conductive, non-sparking properties enhance safety in electrical rooms and zones with solvent vapors, and the high-friction surface reduces slip incidents in wet, oily, or food-grade environments.

Key advantages for plant engineers and EHS leaders include:

- Corrosion resistance against acids, alkalis, and salts—ideal for chemical, wastewater, and coastal facilities.

- Lightweight panels that simplify handling, reduce crane time, and allow faster shutdown turnarounds.

- Stable, consistent slip resistance via embedded grit; no need for periodic re-coating like painted steel.

- Thermal and electrical insulation that improves safety and worker comfort.

Zhaojia Composites Co., Ltd brings application experience across industrial sectors, offering engineered spans, custom cut-outs for penetrations, and color options for visual management (e.g., yellow for hazard zones). With in-house quality control and project-based support, the company helps contractors and OEMs specify covered grating that balances load, ergonomics, compliance, and long-term maintenance goals.

Cost, Maintenance & User Experience

Total cost of ownership is where FRP covered grating stands out. While upfront material costs may be comparable to or slightly higher than painted carbon steel in some regions, the lifecycle picture shifts quickly. FRP does not require galvanizing, periodic repainting, or corrosion touch-ups. Its slip-resistant surface is integral, so facilities avoid recurring anti-skid recoats. That translates to fewer shutdowns and lower maintenance labor—a critical advantage for plants seeking to maximize uptime and control OPEX.

Users in the Manufacturing of building materials and other building components sector often highlight three outcomes: installation speed (thanks to lighter panels and straightforward fastening), improved safety perception among operators (solid top plus high-grip surface), and more predictable budgeting (reduced corrosion-related surprises). Many facilities have replaced legacy steel grating in washdown or chemical zones with FRP covered grating to stabilize performance over time and streamline inspection routines. Zhaojia Composites Co., Ltd supports ROI analysis with span/load guidance, material selections aligned to chemical exposures, and packaging that reduces on-site waste and handling time.

Sustainability & Market Trends in manufacturing

Across manufacturing, specifiers are prioritizing solutions that improve safety and reduce lifecycle impact. FRP covered grating supports these goals by extending service life in corrosive settings, eliminating galvanization and frequent repainting, and minimizing unplanned maintenance. Emerging resin technologies and process controls are lowering VOCs during production, while the long in-service life reduces material turnover. For end-of-life, repurposing strategies and cement co-processing pathways are gaining traction, and longer replacement cycles inherently curb waste generation.

Regulatory attention to worker safety (slip resistance, electrical insulation, fire performance) and asset integrity in corrosive environments continues to drive adoption of non-metallic structural components. Zhaojia Composites Co., Ltd is investing in resin optimization, surface performance, and lean manufacturing practices to reduce scrap and energy intensity. Compliance documentation, safety data, and application-specific recommendations are available to help engineering, procurement, and construction teams align with internal ESG frameworks and evolving codes without sacrificing performance or schedule.

Conclusion on covered grating, grating cover, frp grating manufacturer from Zhaojia Composites Co., Ltd

FRP covered grating brings enduring value to manufacturing, building materials, and non-metallic structural component applications by combining corrosion resistance, reliable slip performance, and low maintenance into a single, high-performance platform solution. With engineering support, customization, and consistent quality, Zhaojia Composites Co., Ltd is a dependable partner for B2B decision makers seeking safer floors, tighter containment, and better lifecycle economics.

Contact us: email: admin@zjcomposites.com

Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025