loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp vessel with multiport valve

Understanding FRP Vessels with Multiport Valves A Comprehensive Overview

Fiber Reinforced Plastic (FRP) vessels are becoming increasingly popular in various industrial applications due to their lightweight, corrosion-resistant, and durable characteristics. These vessels are ideal for storing and transporting a range of chemicals and liquids, particularly in industries like petrochemicals, food processing, and wastewater treatment. The incorporation of multiport valves into FRP vessels enhances their functionality, allowing for efficient fluid control and distribution.

The Basics of FRP Vessels

FRP vessels are constructed from a composite material that consists of plastic reinforced with fibrous materials, usually glass fibers. This combination offers a unique balance of strength and weight, making FRP vessels a preferred option over conventional materials like steel or concrete in many applications. The manufacturing process involves a variety of techniques, including hand lay-up, filament winding, and resin transfer molding, which contribute to the vessel's structural integrity and longevity.

One of the standout features of FRP vessels is their ability to resist corrosion from aggressive chemicals, which significantly prolongs their service life. Unlike metal vessels, FRP does not rust or corrode, making it an ideal choice for environments where chemicals frequently come into contact with storage systems. Furthermore, FRP's lightweight nature allows for easier handling and installation.

The Role of Multiport Valves

Multiport valves play a crucial role in enhancing the functionality of FRP vessels. A multiport valve is designed to control the flow direction of fluids by allowing them to pass through several ports within the same valve. This feature is particularly beneficial in complex piping systems, as it allows for multiple connections and configurations without the need for several individual valves.

The design of a multiport valve usually incorporates a central body with multiple outlet ports. By turning a handle or actuator, the valve can be adjusted to direct fluid to specific ports, enabling efficient management of fluid flow both in and out of the FRP vessel. This capability is essential in scenarios where the mixing of different substances or products is required, or where precise control over the discharge of materials is necessary.

frp vessel with multiport valve

Advantages of Combining FRP Vessels with Multiport Valves

1. Enhanced Operational Efficiency The combination of FRP vessels with multiport valves allows for streamlined operations. Operators can easily control the flow of liquids, divert materials to different processing lines, or isolate sections of a system when necessary. This flexibility boosts overall efficiency and reduces downtime.

2. Space Saving Utilizing a multiport valve minimizes the number of fittings and valves required in a system, effectively saving space. In industries where floor space is at a premium, this is a significant advantage.

3. Reduced Maintenance Costs The integration of multiport valves reduces the number of potential leak points in a system, which can lead to significant reductions in maintenance costs and downtime. Furthermore, the corrosion resistance of FRP vessels means that maintenance requirements are lower compared to traditional metal tanks.

4. Safety Improvements With fewer connections and potential leak points, the risk of hazardous spills is minimized. Moreover, FRP’s non-reactive properties ensure that the vessel remains safe to handle, even in the presence of aggressive chemicals.

5. Customizability Both FRP vessels and multiport valves can be tailored to specific applications. This means that industries can design systems that meet their unique requirements, whether that involves certain sizes, shapes, or port configurations.

Conclusion

The integration of FRP vessels with multiport valves showcases a remarkable advancement in fluid handling technology. By leveraging the lightweight, corrosion-resistant nature of FRP and the versatile capabilities of multiport valves, industries can achieve greater efficiency, safety, and reliability in their operations. As demand for innovative and effective storage solutions continues to rise, the pairing of these technologies will undoubtedly remain a focal point for engineering advancements in various sectors. By focusing on the continuous improvement and customization of these systems, industries can adapt to the ever-evolving challenges of fluid management, ensuring both efficiency and safety in their processes.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

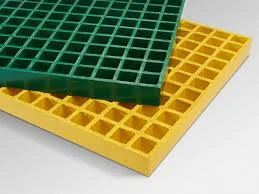

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025