loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp pressure vessel tank

Understanding FRP Pressure Vessel Tanks An Overview

Fiberglass Reinforced Plastic (FRP) pressure vessel tanks have become increasingly popular in various industries due to their exceptional properties and versatility. These tanks are utilized in processes that require the storage and containment of liquids and gases under pressure. The combination of fiberglass and resin provides a strong, lightweight, and corrosion-resistant solution, making FRP tanks an ideal choice for numerous applications.

Composition and Structure

FRP pressure vessels are made from a composite material consisting of fiberglass fibers embedded in a polymer matrix, usually a type of resin, like unsaturated polyester or vinyl ester. The structure of an FRP tank can vary based on the application and the specific requirements of the industry it serves. These vessels are typically crafted through a process known as filament winding, where resin-impregnated fibers are wound around a mold in a specific orientation. This technique ensures that the strength of the tank is maximized, particularly in areas subjected to the highest stress.

One of the remarkable features of FRP pressure vessels is their ability to be tailored according to specific needs. By changing the composition of the fiberglass and resin, manufacturers can optimize the tanks for thermal resistance, chemical compatibility, and other unique operational conditions.

Advantages of FRP Tanks

1. Corrosion Resistance One of the most significant advantages of FRP pressure vessel tanks is their resistance to corrosion. Unlike traditional materials, such as steel, which can rust and degrade when exposed to harsh chemicals, FRP tanks maintain their integrity. This property is particularly valuable in industries such as chemical processing, wastewater treatment, and oil and gas.

2. Lightweight The lightweight nature of FRP allows for easy transportation and installation. This attribute not only reduces the costs associated with handling heavy materials but also simplifies the design of support structures, making it a cost-effective solution in the long run.

3. Strength Despite being lightweight, FRP pressure vessels offer excellent strength-to-weight ratios. Their structural integrity allows them to withstand high pressures, making them suitable for various applications that require robust containment solutions.

4. Thermal Insulation FRP materials provide good thermal insulation properties. This feature is particularly beneficial in industries that deal with temperature-sensitive materials, as it helps maintain consistent temperatures inside the tank.

frp pressure vessel tank

5. Longevity and Durability FRP tanks have a long lifespan, often exceeding 20 years with proper maintenance. Their resistance to environmental factors such as UV radiation also contributes to their longevity, making them a reliable choice for both indoor and outdoor applications.

Applications of FRP Pressure Vessel Tanks

FRP pressure vessels are utilized in a diverse range of applications

- Chemical Storage Many chemical manufacturing processes require the safe storage of hazardous materials. FRP tanks provide an ideal solution due to their resistance to chemical corrosion.

- Water Treatment In the water treatment industry, FRP tanks are often used for storing chemicals, like chlorine and potassium permanganate, which are essential for purifying water.

- Oil and Gas The oil and gas sector benefits from FRP tanks in both upstream and downstream applications, where they might be used for storage, processing, or transportation of various liquids and gases.

- Food and Beverage Due to their non-reactive nature, FRP tanks can also be found in the food industry, particularly for storing ingredients and various liquid products.

Conclusion

FRP pressure vessel tanks are an innovative solution that combines strength, durability, and resistance to corrosion. Their longevity and lightweight nature make them applicable in various industries, addressing the challenges presented by traditional metal tanks. As industries continue to evolve, the demand for advanced materials like FRP is likely to grow, positioning these tanks as a cornerstone in modern engineering and manufacturing processes. Embracing the advantages of FRP not only enhances operational efficiency but also contributes to safer handling and storing of substances that are crucial to the functioning of multiple sectors. As we look towards the future, the role of FRP pressure vessel tanks will undoubtedly become more prominent, paving the way for improved industrial practices and environmental sustainability.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

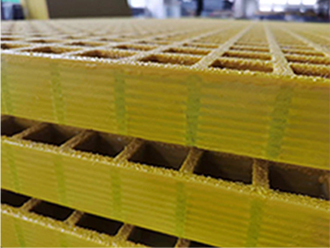

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025