loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp pressure vessel price

The Dynamics of FRP Pressure Vessel Pricing

In recent years, the demand for Fiber Reinforced Polymer (FRP) pressure vessels has surged across various industries, driven by their unique benefits such as strength, durability, and resistance to corrosion. As businesses look to adopt innovative materials for their industrial applications, understanding the factors influencing FRP pressure vessel prices becomes crucial.

Understanding FRP Pressure Vessels

FRP pressure vessels are composite materials made by blending fibers, typically glass or carbon, with a polymer matrix. These vessels are extensively used in industries like chemical processing, oil and gas, water treatment, and aerospace due to their excellent mechanical properties and lightweight nature. Unlike traditional metal tanks, FRP vessels do not corrode, which can enhance their longevity and reduce maintenance costs.

Factors Influencing Pricing

1. Material Quality The type and quality of fibers and resins used significantly impact the cost. High-performance fibers, such as carbon fibers, cost more than standard glass fibers. Likewise, the resin type, whether thermosetting or thermoplastic, also plays a role in determining the price. Businesses must find a balance between performance and cost-efficiency.

2. Manufacturing Processes The production method employed can affect pricing. Techniques like filament winding, hand lay-up, and resin transfer molding (RTM) come with differing labor costs, production times, and complexities. Filament winding, while more expensive due to automated equipment, can produce vessels with superior strength and uniformity, making them favorable in highly demanding conditions.

3. Size and Customization The dimensions and design of the pressure vessel are critical price determinants. Custom designs that cater to specific requirements will generally cost more due to the additional engineering efforts involved. Larger vessels typically incur higher costs not only due to raw materials but also due to handling and transport considerations.

4. Regulatory Compliance and Certification Many industries require vessels to meet strict regulatory standards and certifications (such as ASME, API, or ANSI). Achieving and maintaining these standards requires investment in quality assurance processes and may involve additional testing, which can escalate costs.

frp pressure vessel price

5. Market Dynamics Like any other product, market demand and supply conditions affect pricing. In a thriving industrial landscape where the demand for FRP vessels is robust, prices may rise. Conversely, if new materials enter the market or technological advancements lower production costs, prices might decrease.

6. Geographical Factors The location of production facilities and the logistics of transporting FRP pressure vessels can also influence pricing. Regions with higher labor costs or stringent regulatory environments may have elevated prices compared to regions with more favorable economic conditions.

Cost vs. Value Analysis

While the upfront cost of FRP pressure vessels may be higher compared to traditional materials, the long-term savings can justify the initial investment. Their resistance to environmental degradation reduces the frequency and costs associated with replacements or repairs. Additionally, lower maintenance requirements can lead to significant cost savings over the vessel's lifespan.

Moreover, the lightweight nature of FRP pressure vessels can result in decreased transportation and installation costs, particularly in challenging settings. Hence, organizations must consider the total cost of ownership rather than just the initial purchase price when making procurement decisions.

Future Trends

As industries evolve, so do the materials utilized in manufacturing pressure vessels. Advances in composite materials and manufacturing technologies are expected to lead to a more competitive pricing environment. Innovative designs and increased automation could further optimize FRP production, potentially lowering costs while enhancing performance.

In conclusion, the pricing of FRP pressure vessels is influenced by various interrelated factors, including material quality, manufacturing processes, size, customization, regulatory compliance, market dynamics, and geographical elements. As industries continue to recognize the value and long-term savings associated with FRP pressure vessels, understanding these pricing dynamics will be essential for making informed purchasing decisions. The future holds promise for more affordable and advanced solutions, ensuring that FRP continues to play a critical role in the industrial landscape.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

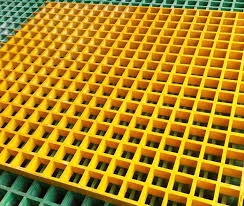

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025