loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits of FRP C Channels in Construction Applications

Understanding FRP C Channels A Comprehensive Guide

In the realm of modern construction and engineering, materials play a crucial role in ensuring the durability, strength, and efficiency of structures. Among the innovative options available today, Fiber Reinforced Polymer (FRP) C Channels have emerged as a popular choice for various applications. This article delves into the characteristics, advantages, and applications of FRP C Channels, highlighting their significance in contemporary construction practices.

What are FRP C Channels?

FRP C Channels are structural components made from Fiber Reinforced Polymer, which is a composite material comprised of a polymer matrix reinforced with fibers, typically glass or carbon. The “C” designates the shape of the channel, which resembles the letter C when viewed in cross-section. This configuration offers a combination of strength and lightweight characteristics, making it an ideal choice for structural applications.

Key Characteristics

1. Lightweight One of the standout features of FRP C Channels is their lightweight nature. Compared to traditional materials like steel and aluminum, FRP C Channels significantly reduce the overall weight of structures. This advantage not only facilitates easier handling and installation but also contributes to lower transportation costs.

2. Corrosion Resistance FRP C Channels exhibit exceptional resistance to a variety of environmental conditions, including moisture, chemicals, and UV exposure. This corrosion resistance extends the lifespan of structures, reducing maintenance costs and enhancing long-term performance.

3. High Strength-to-Weight Ratio The integration of fiber reinforcement in FRP materials gives C Channels a remarkable strength-to-weight ratio. This means that they can support substantial loads without the bulkiness associated with traditional materials, making them suitable for various structural applications.

4. Design Flexibility FRP C Channels can be manufactured in a range of sizes and configurations to meet specific project requirements. Their versatile design allows engineers and architects to incorporate them creatively into both structural and aesthetic elements of buildings and infrastructures.

Advantages of Using FRP C Channels

- Durability The longevity of FRP C Channels, thanks to their corrosion resistance and minimal maintenance requirements, makes them a cost-effective solution over time. Structures that utilize FRP materials tend to have longer service lives, reducing the frequency and cost of repairs.

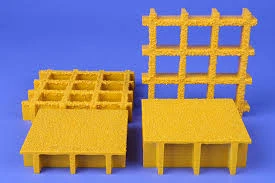

frp c channel

- Environmental Benefits Many FRP materials can be produced with recycled fibers, making them an environmentally friendly option. Additionally, their lightweight nature contributes to lower energy consumption during transportation and installation.

- Enhanced Safety The non-conductive properties of FRP materials add an additional layer of safety, especially in applications where electrical conductivity could pose a risk. Additionally, their resistance to chemicals avoids potential hazardous situations in industrial environments.

Applications

FRP C Channels are being increasingly adopted across various industries due to their unique properties. Some notable applications include

1. Construction and Building In commercial and residential constructions, FRP C Channels are used for framing, reinforcement, and support elements. Their ability to withstand harsh environmental conditions makes them ideal for coastal and industrial settings.

2. Bridges and Infrastructure Due to their lightweight and durable characteristics, FRP C Channels are employed in the construction of pedestrian bridges, boardwalks, and other structures that require both strength and resistance to corrosion.

3. Marine Applications The marine industry benefits greatly from FRP C Channels, where their resistance to saltwater and harsh weather conditions enhances the longevity of docks, piers, and boat supports.

4. Industrial Contexts In chemical processing plants and other industrial environments, the resistant properties of FRP C Channels make them suitable for supporting pipe systems and equipment exposed to aggressive chemicals.

Conclusion

In conclusion, FRP C Channels represent a remarkable advancement in construction materials, combining the benefits of lightweight design, strength, and corrosion resistance. Their versatility and environmental advantages make them an increasingly popular choice for engineers and architects looking to enhance the performance and longevity of their structures. As technology continues to evolve, the use of materials like FRP will likely expand, paving the way for innovative engineering solutions that meet the demands of modern construction. Whether in residential buildings, infrastructure, or industrial applications, FRP C Channels are poised to make a lasting impact in the world of structural engineering.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025