loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

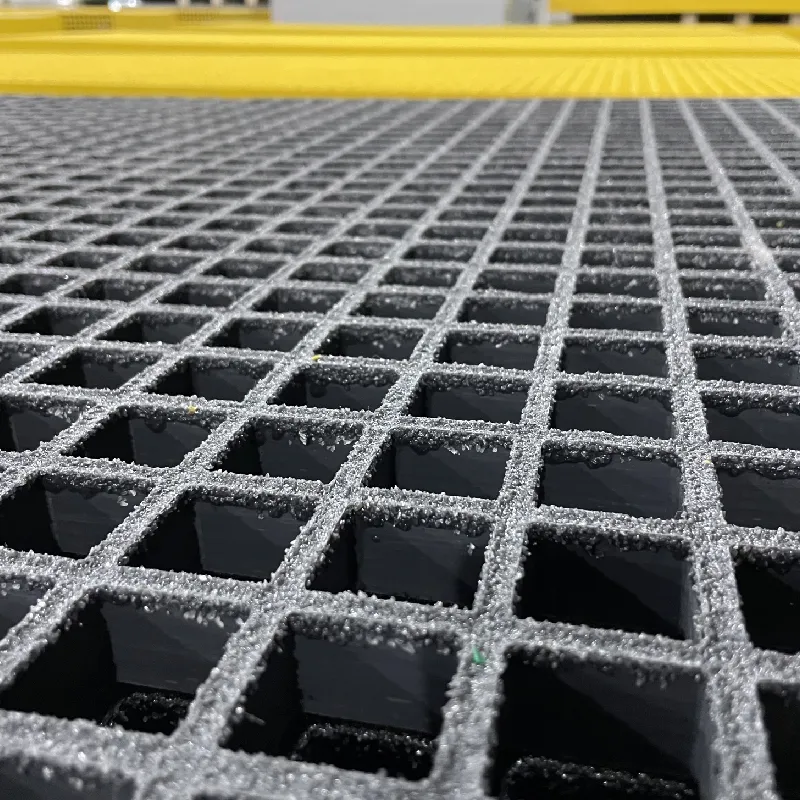

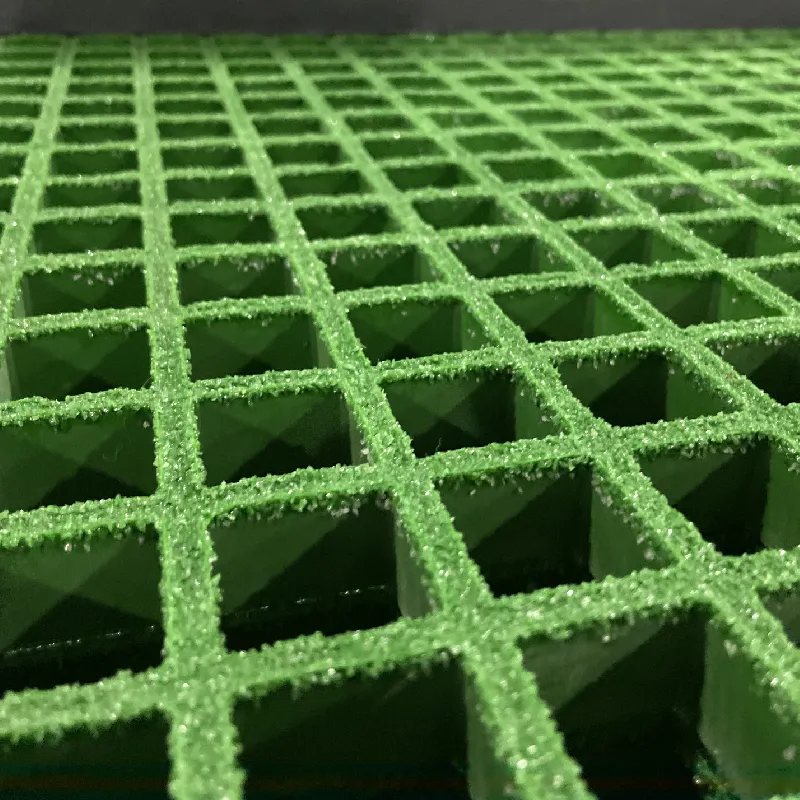

FRP Micro Mesh Grating - Anti-Slip, Corrosion-Resistant

Field Notes on FRP Micro Mesh: safer decks, quieter budgets

If you’ve spent time around chemical plants or on salty piers (I surely have), you’ve watched metal walkways rust into maintenance headaches. That’s why Frp Micro Mesh Grating has been creeping into specs everywhere—quietly at first, then all at once. ZJ Composites’ “Holiday Special Offers GRP FRP Gratings Fiberglass Grates” line is a good snapshot of where the market is going: corrosion-resistant, high slip resistance, and surprisingly light to install.

Industry trend check

The shift from steel to Frp Micro Mesh Grating is driven by lifecycle math and safety. Real buyers aren’t just counting capex; they’re tallying downtime, repaint cycles, and slip incidents. Many customers say the ROI crosses over in 18–36 months in marine and wastewater settings. Also, plants are standardizing on flame-rated resins and asking for audited quality (ISO 9001, third-party lab tests). That wasn’t common five years ago.

How it’s built (materials, methods, tests)

- Materials: E-glass roving, isophthalic or vinyl ester resin, UV inhibitors, Al2O3 anti-slip grit on top (optional).

- Method: Molded micro-mesh panel; fine-cell top ≈ 12–13 mm grid integrated over a structural base. Pultruded variants exist for higher directional stiffness, but molded wins on isotropy.

- Cure & finish: Controlled gel, post-cure; grit broadcast; trim and seal cut edges.

- Testing: ASTM D790 flexural, D2584 ash content, E84 flame spread; coefficient of friction per D2047 (or local equivalents). Real-world use may vary.

- Service life: around 20–30 years in C5-M marine atmospheres with basic washdowns; longer inland.

Representative specifications

| Parameter | Typical Value (≈) | Notes |

|---|---|---|

| Panel thickness | 25–38 mm | Micro mesh top integrated |

| Micro mesh opening | ≈ 12 × 12 mm | Prevents small tool drop-through |

| Flexural strength | ≈ 220–300 MPa | ASTM D790, 23°C |

| Flame rating | FSI ≤ 25 | ASTM E84 Class 1 resin |

| Coefficient of friction | Dry ≈ 0.8; Wet ≈ 0.65 | Grit surface, D2047 |

| Operating temp | -40 to 110°C | Resin-dependent |

Where it’s used (and why)

- Wastewater walkways, clarifier bridges, odor-control covers.

- Marine docks, ferry terminals; less corrosion, quieter footfall.

- Chemical plants and battery rooms—non-conductive and spark resistant.

- Food processing mezzanines; micro mesh helps with cart wheels and hygiene.

Vendor snapshot (real-world buying factors)

| Vendor | Lead Time | Certs | Customization | Warranty |

|---|---|---|---|---|

| ZJ Composites (Hebei, China) | ≈ 2–4 weeks | ISO 9001; third-party tests | Resin, color, grit, cut-to-size | Up to 10 years (use-dependent) |

| Local steel fabricator | ≈ 1–3 weeks | Material certs | High on shapes, low on corrosion-proofing | Typically 1–3 years |

| Generic import FRP supplier | ≈ 4–8 weeks | Varies | Limited options | 3–5 years |

Customization and delivery

ZJ Composites offers custom panels cut, banded, and drilled—less site noise and faster handrails install. Resin upgrades (vinyl ester for harsh chem), bright safety colors, and closed-top plates are common tweaks. Facility address for due diligence: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China.

Field results and feedback

Case in point: a coastal wastewater plant swapped steel for Frp Micro Mesh Grating on 220 m of catwalks. Install crew reported a 35% time cut (no hot-works permits, lighter lifts). After 18 months, grit wear measured

Quick test data snapshot

- ASTM D790 flexural: 250 MPa avg (n=5, 25 mm panel), modulus ≈ 17 GPa.

- ASTM E84: FSI 20, SDI

- QUV (1000 h): strength retention ≈ 85–90% with UV package.

- Electrical: non-conductive; dielectric strength resin-dependent.

Bottom line: Frp Micro Mesh Grating isn’t a silver bullet, but in corrosive, people-moving areas, it’s edging out steel on total cost and safety.

Authoritative citations

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025