loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Covered Grating: Sealed, Anti-Slip, Corrosion-Resistant FRP

Field Notes on FRP/GRP Solid-Top Grating: What Specifiers Get Right (and Wrong)

If you spend time around chemical plants or water treatment decks (I do, more than I planned), you learn fast why covered grating has momentum. It’s corrosion‑proof where steel sulks, it’s quiet under cart traffic, and—surprisingly—it keeps odors and debris from dropping through. Many customers say the extra stiffness is the clincher; in fact, this solid-top FRP design clocks in around 30% stiffer than open mesh, which you notice when you’re pushing a loaded trolley at 6 a.m.

Product snapshot

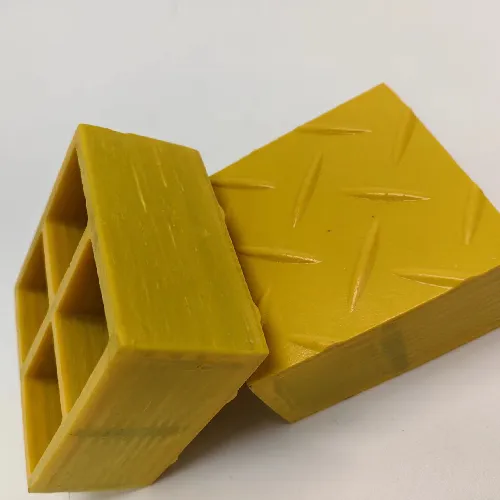

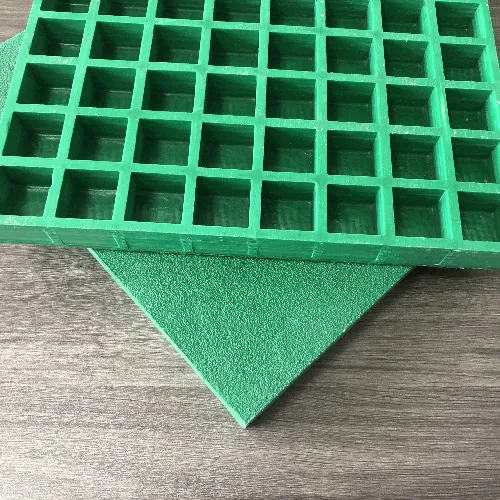

Corrosion Resistant and Slip Resistant FRP GRP Fiberglass covered grating from ZJ Composites (Origin: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China) blends a molded FRP grid with a co‑molded solid plate and a gritted surface. To be honest, it’s the “no more dropped bolts and drips” aspect that maintenance teams rave about.

| Spec | Details (≈, real‑world use may vary) |

|---|---|

| Panel sizes | ≈ 1000×3000 mm, 1220×3660 mm; custom cut |

| Thickness options | 25 / 38 / 50 mm grid with 3–5 mm top plate |

| Resins | Orthophthalic, Isophthalic, Vinyl ester; fire-retardant grades |

| Slip resistance | Gritted surface COF dry ≈ 0.7–0.9; wet ≈ 0.6–0.8 (lab) |

| Mechanical | Flexural per ASTM D790; +30% stiffness vs. open mesh |

| Fire | ASTM E84 Class 1 options |

| Chemicals | Resistance profiled per ASTM D543 |

| Service life | 20–30 years in typical industrial duty |

Process flow and QA

- Materials: E‑glass rovings, corrosion‑resistant resins, aluminum oxide grit, UV inhibitors.

- Method: Molded FRP grid with co‑molded solid plate; edges sealed; non‑sparking finish.

- Testing: ASTM D790 (flexural), D638 (tensile), D2583 (Barcol), D543 (chem), E84 (flame).

- Deflection control: typical L/200 design limit under uniform load.

- QC: ISO 9001 systems; traceability by batch; random COF checks (wet/oily).

Where it shines

covered grating makes sense on wastewater aeration decks, chemical loading bays, food & beverage walkways (no drip‑through), pulp & paper mezzanines, offshore platforms, and data‑center rooftop access where odor control and clean under‑floor spaces matter.

Real‑world notes (short case studies)

covered grating at a Midwest wastewater plant replaced rusted bar grating; after one winter, maintenance reported zero ice‑bonding and no fastener drop‑through—COF wet averaged ≈0.74 in spot checks. In a beverage bottling line, swapping to vinyl‑ester solid‑top reduced caustic splash staining and, oddly enough, made cart traffic calmer (operators said it felt “less bouncy”).

Vendor comparison (quick take)

| Vendor | Certs | Lead time | Customization | Notes |

|---|---|---|---|---|

| ZJ Composites | ISO 9001; E84 data on request | ≈ 2–4 weeks | Resin, color, grit, cut‑outs | Origin: Hebei, China; solid documentation set |

| Generic Importer A | Basic factory QC | ≈ 6–8 weeks | Limited | Spotty test reporting |

| Metal Fabricator B | ISO 9001 | ≈ 3–5 weeks | Steel/aluminum only | Higher corrosion OPEX |

Customization and install tips

Order covered grating with vinyl‑ester resin for harsh chem, choose grit size to balance cleanability vs. slip, and specify seal‑coated cuts. Pre‑drill for FRP clips, keep spans conservative (I prefer L/250 for cart lanes), and request COF and E84 reports tied to your exact resin.

Certifications and data available on request. For quoting, note panel thickness, plate thickness, span, live load, environment, and any penetrations. Honestly, that upfront detail saves weeks.

Authoritative citations

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025