loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Applications and Benefits of Structural Fiber Reinforced Polymers

Understanding Structural FRP A Game Changer in Construction

In the ever-evolving landscape of construction materials, Fiber Reinforced Polymer (FRP) has emerged as a revolutionary solution, particularly in structural applications. Composed of a polymer matrix reinforced with fibers, usually glass, carbon, or aramid, FRP combines the benefits of high strength, low weight, corrosion resistance, and flexibility. Its unique properties make it a formidable choice for modern infrastructure projects, bridging the gap between traditional materials and the demands of contemporary engineering challenges.

Advantages of Structural FRP

1. Strength and Weight One of the most significant advantages of FRP is its exceptional strength-to-weight ratio. This allows engineers and architects to design lighter structures without compromising strength. For instance, FRP reinforcement bars (rebar) can replace traditional steel in concrete, resulting in lighter beams and columns. This reduction in weight simplifies transportation and installation, offering both economic and logistical benefits.

2. Corrosion Resistance Corrosion is a leading cause of structural deterioration, particularly in environments exposed to saline, acidic, or industrial conditions. Unlike steel, which is susceptible to rust, FRP does not corrode, making it an ideal choice for structures near bodies of water or in harsh chemical environments. This property not only extends the lifespan of infrastructure but also reduces maintenance costs significantly.

3. Design Flexibility The versatility of FRP allows for innovative designs that were previously challenging to achieve with conventional materials. FRP can be molded into various shapes and sizes, facilitating the creation of complex geometries and aesthetic elements in construction. This adaptability opens new avenues for creative architectural solutions, enabling structures that are not only functional but also visually appealing.

4. Sustainability As the construction industry increasingly prioritizes sustainability, FRP stands out as an environmentally friendly option. The production and transport processes involved in FRP manufacturing typically require less energy compared to traditional building materials. Moreover, its longevity and resistance to harsh conditions contribute to a decreased need for repair and replacement, aligning with the principles of sustainable construction.

Applications of Structural FRP

structural frp

The applications of structural FRP are vast and varied. In the transportation sector, FRP is utilized in bridge construction, where its lightweight nature reduces the load on foundations while maintaining durability. Additionally, FRP can be found in buildings, wastewater treatment facilities, and even in retrofitting existing structures. Its use in reinforcing concrete structures has gained popularity, particularly in seismic-prone areas, where FRP can enhance flexural strength and ductility.

In marine environments, such as piers and docks, FRP's corrosion resistance makes it indispensable. It ensures longevity and minimizes maintenance needs, contributing to cost savings over time. Similarly, in the aerospace and automotive industries, the lightweight properties of FRP are harnessed to improve fuel efficiency and performance.

Challenges and Future Directions

While the benefits of structural FRP are substantial, challenges remain. The initial costs of FRP materials can be higher than those of traditional options, which may deter some builders. Additionally, a general lack of familiarity among engineers and contractors with FRP technology can lead to hesitance in its adoption.

However, ongoing research and development are addressing these issues. As awareness of FRP's advantages grows and production techniques advance, costs are expected to decrease. Furthermore, the establishment of design codes and standards specific to FRP will foster greater confidence among industry professionals.

Conclusion

In conclusion, structural FRP represents a significant advancement in construction materials, offering a combination of strength, durability, and design flexibility that traditional materials often lack. As the industry moves toward more sustainable practices, the integration of FRP into infrastructure projects is likely to become increasingly prevalent. Embracing this innovative material will not only enhance the performance of structures but will also pave the way for a more innovative and sustainable future in construction. The potential of structural FRP is immense, and its impact on the industry is just beginning to unfold.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

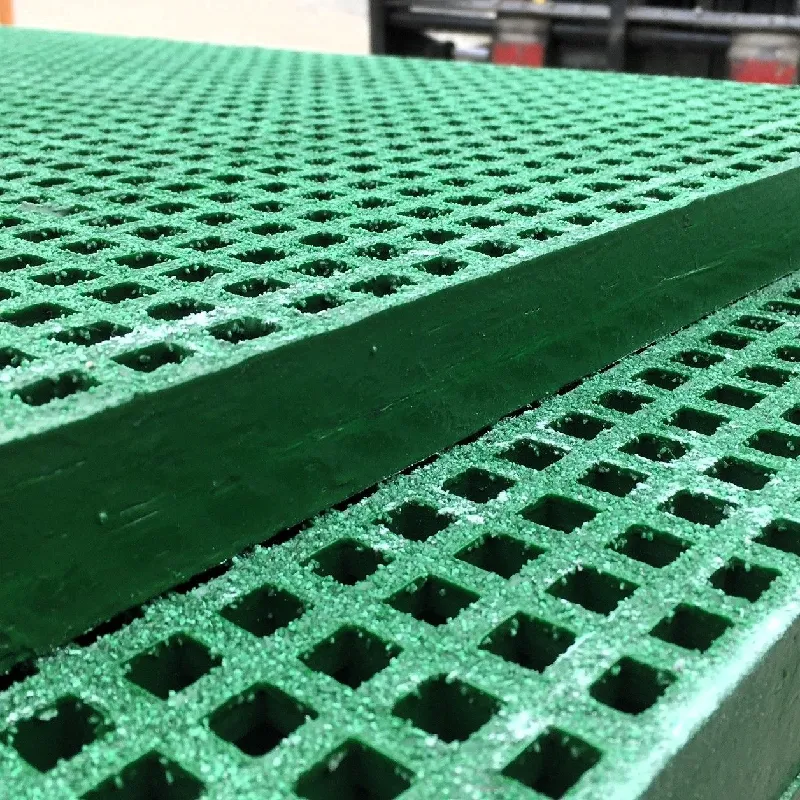

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025