loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

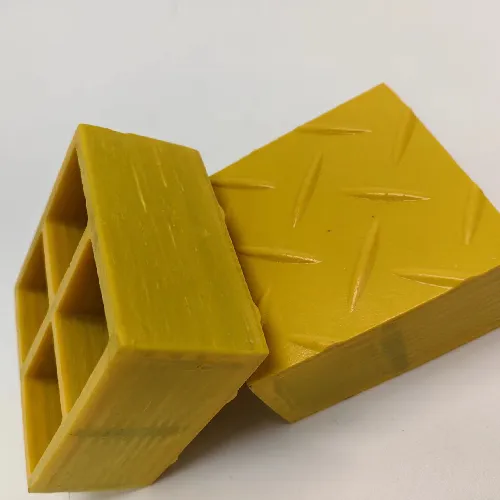

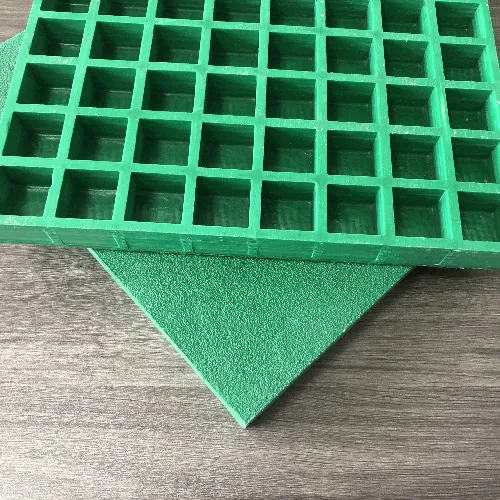

Need Covered Grating—Anti-Slip, Corrosion-Resistant FRP?

If you’re sizing up covered grating for a plant upgrade or a new build, you’ve probably heard the same refrain from maintenance teams: make it safer, lighter, and don’t let it rust. To be honest, that’s exactly where modern FRP/GRP solutions shine. I’ve walked enough mezzanines and catwalks to know—when the top plate is solid and gritted, the footing just feels right, and carts roll smoother. This particular product from ZJ Composites adds ≈30% stiffness over open mesh while keeping the corrosion headaches at bay.

What’s changing in the market (and why it matters)

Across chemical processing, wastewater, and food facilities, I’m seeing a steady pivot from galvanized steel to covered grating made from fiberglass. Reasons aren’t mysterious: non-sparking, lighter lifts for crews, consistent slip resistance even when oily or wet, and fewer shutdowns for repainting. Surprisingly, even marine yards—once die-hard steel fans—are switching for the odor-control benefit of a sealed, solid top.

Core technical specs (quick glance)

| Parameter | Typical Value (≈) |

|---|---|

| Construction | Molded FRP/GRP grating with solid, gritted cover plate |

| Resin systems | Orthophthalic, Isophthalic, Vinyl Ester, Phenolic (per application) |

| Panel sizes | up to ~1220 × 3660 mm; custom cut available |

| Cover plate thickness | 3–5 mm common; other options on request |

| Slip resistance | Quartz-grit top; DIN 51130 up to R13 (field conditions vary) |

| Fire performance | ASTM E84 Class 1 possible with VE/phenolic resins |

| Stiffness | ≈30% higher than open mesh of similar depth |

| Service life | 20–30 years in typical industrial environments |

How it’s made (process flow)

- Materials: glass roving, thermoset resin (per chemical exposure), mineral grit, UV-inhibitors.

- Molding: heated mold forms the FRP grid; cover plate is bonded/laminated to create a solid top.

- Surface: silica/alumina grit broadcast for consistent coefficient of friction.

- Testing: flexural (ASTM D790), tensile (D638), compressive (D695), flame (E84), burn (D635), slip (DIN 51130/ASTM E303).

- QA & traceability: batch cure logs, barcol hardness checks, thickness and bond integrity audits.

Where it works best

- Wastewater walkways and odor-control covers

- Chemical plants and plating lines (non-sparking, corrosion-resistant)

- Food & beverage bottling platforms (solid top prevents drip-through)

- Marine docks, pulp & paper mills, battery rooms, semiconductor utilities

Quick case note: a bottling facility swapped steel plates for covered grating; cart vibration dropped noticeably and housekeeping loved the sealed top—no more product falling through to conveyors below. Maintenance told me, “We haven’t had to touch it since install,” which is music to any plant manager’s ears.

Vendor snapshot (what buyers compare)

| Vendor | Core Material | Slip Rating | Corrosion Resistance | Lead Time | Certifications |

|---|---|---|---|---|---|

| ZJ Composites (Origin: No. 9 Xingyuan S. St., Zaoqiang, Hebei, China) | Molded FRP with solid top | Up to R13 (gritted) | Excellent, resin-dependent | Around 2–5 weeks | ISO 9001; ASTM/EN test reports |

| Steel Grating Co. (galv.) | Carbon steel w/ plate | Depends on checker plate | Good, but paint upkeep | 1–3 weeks | Mill certs; OSHA fitment |

| Generic FRP Import | Pultruded FRP | R11–R12 typical | Varies by resin | 3–8 weeks | Varies; request data |

Customization and options

- Resin selection for acids/alkalis/UV; FDA-compliant options on request.

- Top textures: medium or aggressive grit; color coding for zones.

- Cut-to-size panels, beveled edges, embeds, and stainless clips.

- Earthing straps for mixed-metal interfaces (yes, even non-conductive installs can need bonding practices).

Testing, data, and compliance

- Typical results: flexural strength per ASTM D790 often >200 MPa; Barcol hardness per ASTM D2583 ≈ 40–55 (resin-dependent).

- Flame/smoke: ASTM E84 Class 1 available; ASTM D635 self-extinguishing resins for safety-critical zones.

- Slip resistance: DIN 51130 up to R13; ASTM E303 pendulum values in wet/oily conditions remain high—real-world use may vary.

- Safety fit: meets OSHA 29 CFR 1910 walking-working surface intent when properly installed.

- Quality system: ISO 9001 manufacturing; material REACH/RoHS documentation on request.

Bottom line? For heavy foot traffic and carts in corrosive or hygiene-sensitive areas, covered grating gives you the solid, sealed surface you need without the weight and rust tax of steel. It’s a practical upgrade that—speaking frankly—tends to pay for itself in avoided maintenance.

Authoritative citations

- ASTM Standards for FRP: D790, D638, D695, D635; ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials.

- DIN 51130 – Testing of floor coverings; determination of anti-slip properties.

- OSHA 29 CFR 1910 – Walking-Working Surfaces requirements.

- ISO 9001 – Quality management systems for manufacturing consistency.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025