loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Фев . 16, 2025 10:11

Back to list

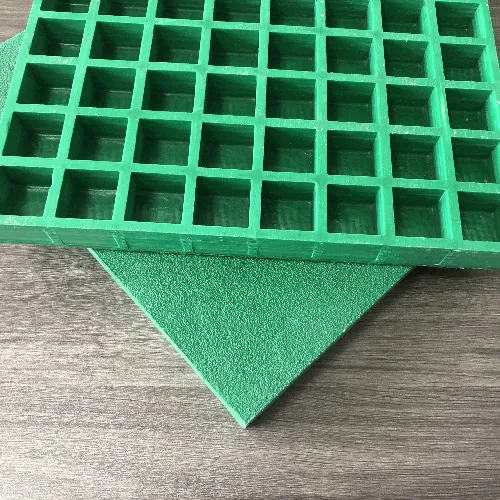

Anti- Corrosion Cost Effective FRP Pultrusion Grating

Pultruded FRP grating has become increasingly relevant in industries requiring durable, lightweight, and corrosion-resistant solutions. Its unique composition and manufacturing process offer numerous advantages over traditional materials like steel, aluminum, or wood. This article delves into the intrinsic qualities and applications of pultruded FRP grating, underscoring its unmatched attributes in industrial settings.

A testament to its versatility, pultruded FRP grating finds widespread application across diverse sectors. In maritime industries, it is employed on docks and ships due to its resistance to sea-weather conditions. Water treatment facilities utilize it for walkways and structural covers, capitalizing on the material's resistance to moisture and chemicals. Additionally, in the building and construction industry, architects and engineers specify pultruded FRP grating for its innovative design possibilities and durability. Economic efficiency is another pivotal aspect. The initial investment in pultruded FRP may be higher than conventional materials, yet the cost-saving potential over time is significant. Its minimal maintenance requirements, coupled with an extended service life, provide an attractive return on investment. Furthermore, its recyclability aligns with growing environmental sustainability goals, further enhancing its appeal as a future-proof material solution. As experts continue to innovate and push the bounds of composite materials, the role of pultruded FRP grating is set to expand. Ongoing research and development efforts focus on enhancing its mechanical properties and integrating smart technologies, such as sensors for environmental monitoring, further elevating its position as a material of choice. In conclusion, pultruded FRP grating represents an intersection of advanced material technology and practical utility. This high-performance composite offers an array of benefits—safety, corrosion resistance, and economic viability—making it indispensable in challenging industrial environments. Its adaptation and application continue to rise, backed by expertise and trust in its enduring capabilities. As industries evolve, pultruded FRP grating will undoubtedly remain a cornerstone of modern infrastructure, meeting the complex demands of contemporary construction and engineering with unmatched proficiency.

A testament to its versatility, pultruded FRP grating finds widespread application across diverse sectors. In maritime industries, it is employed on docks and ships due to its resistance to sea-weather conditions. Water treatment facilities utilize it for walkways and structural covers, capitalizing on the material's resistance to moisture and chemicals. Additionally, in the building and construction industry, architects and engineers specify pultruded FRP grating for its innovative design possibilities and durability. Economic efficiency is another pivotal aspect. The initial investment in pultruded FRP may be higher than conventional materials, yet the cost-saving potential over time is significant. Its minimal maintenance requirements, coupled with an extended service life, provide an attractive return on investment. Furthermore, its recyclability aligns with growing environmental sustainability goals, further enhancing its appeal as a future-proof material solution. As experts continue to innovate and push the bounds of composite materials, the role of pultruded FRP grating is set to expand. Ongoing research and development efforts focus on enhancing its mechanical properties and integrating smart technologies, such as sensors for environmental monitoring, further elevating its position as a material of choice. In conclusion, pultruded FRP grating represents an intersection of advanced material technology and practical utility. This high-performance composite offers an array of benefits—safety, corrosion resistance, and economic viability—making it indispensable in challenging industrial environments. Its adaptation and application continue to rise, backed by expertise and trust in its enduring capabilities. As industries evolve, pultruded FRP grating will undoubtedly remain a cornerstone of modern infrastructure, meeting the complex demands of contemporary construction and engineering with unmatched proficiency.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025