loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Фев . 19, 2025 09:06

Back to list

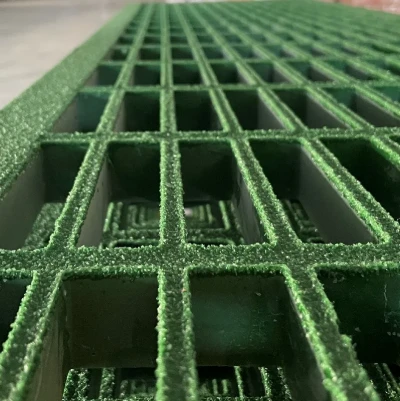

Smaller Open Mesh Area FRP Mini Mesh Grating

Navigating the industrial landscape often involves ensuring safety where flooring solutions are concerned. Non-slip grating is more than just a precautionary measure; it's a critical component that significantly enhances workplace safety. Industries such as oil and gas, food processing, and manufacturing demand flooring that minimizes slipperiness, thus making non-slip grating indispensable.

In terms of authoritativeness, industry standards such as OSHA’s regulations in the U.S. or the UK’s HSE guidelines serve as the benchmark for non-slip grating. Ensuring compliance with these standards not only fosters workplace safety but also instills confidence that the solutions are rigorously tested and validated. Utilizing load tests and slip resistance evaluations can substantiate the grating's efficacy. Leading manufacturers often publish independent testing results, which serves as a testament to their product’s reliability. Trustworthiness in the selection process is bolstered by referencing verified case studies and customer testimonials. Companies that transparently showcase their product’s success in real-world applications typically enjoy greater trust. For instance, a case study detailing how non-slip grating reduced slips and falls by 30% in a high-risk environment could significantly influence decision-making. This transparency is pivotal as it not only reassures buyers of the product’s capabilities but also underscores the manufacturer’s confidence in their offerings. Overall, non-slip grating is not merely an accessory but a necessity in industrial safety infrastructure. Its adoption speaks volumes about a company’s commitment to safeguarding its workforce. As industries evolve, the demand for more sophisticated and reliable non-slip solutions is poised to grow, underlining the grating’s significance in safe operational practices.

In terms of authoritativeness, industry standards such as OSHA’s regulations in the U.S. or the UK’s HSE guidelines serve as the benchmark for non-slip grating. Ensuring compliance with these standards not only fosters workplace safety but also instills confidence that the solutions are rigorously tested and validated. Utilizing load tests and slip resistance evaluations can substantiate the grating's efficacy. Leading manufacturers often publish independent testing results, which serves as a testament to their product’s reliability. Trustworthiness in the selection process is bolstered by referencing verified case studies and customer testimonials. Companies that transparently showcase their product’s success in real-world applications typically enjoy greater trust. For instance, a case study detailing how non-slip grating reduced slips and falls by 30% in a high-risk environment could significantly influence decision-making. This transparency is pivotal as it not only reassures buyers of the product’s capabilities but also underscores the manufacturer’s confidence in their offerings. Overall, non-slip grating is not merely an accessory but a necessity in industrial safety infrastructure. Its adoption speaks volumes about a company’s commitment to safeguarding its workforce. As industries evolve, the demand for more sophisticated and reliable non-slip solutions is poised to grow, underlining the grating’s significance in safe operational practices.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025