loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

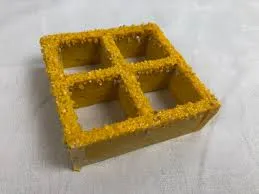

frp grating platform

The Advancements and Applications of FRP Grating Platforms

Fiber Reinforced Plastic (FRP) grating platforms have emerged as a significant innovation in various industries, reflecting a growing trend towards lightweight, durable, and corrosion-resistant materials. These platforms are constructed using a composite of fiberglass and resin, resulting in a material that not only meets the demanding requirements of industrial applications but also offers a host of advantages over traditional materials such as steel or wood.

One of the most notable features of FRP grating is its exceptional strength-to-weight ratio. This property allows for the construction of platforms that are both robust and lightweight. Industries that require elevated walkways or platforms often find FRP grating to be an ideal choice, as it reduces the load on structural supports while maintaining high safety standards. In environments where heavy equipment or personnel are present, the lightweight nature of FRP can lead to significant savings in installation and operational costs.

Moreover, FRP grating platforms excel in corrosive environments. Traditional materials often suffer from rust and degradation when exposed to chemicals or saltwater, ultimately leading to higher maintenance costs and shorter lifespans. In contrast, FRP does not corrode, providing a longer-lasting solution for industries such as oil and gas, wastewater treatment, and chemical processing. By utilizing FRP grating, companies can minimize downtime and maintenance efforts, streamlining operations and increasing efficiency.

Another advantage of FRP grating platforms is their ease of installation. The lightweight design facilitates quick and straightforward installation procedures, often eliminating the need for heavy machinery. This characteristic is particularly beneficial in remote or challenging locations where accessibility can be limited. Workers can often install these platforms with simple tools, reducing labor costs and project timelines.

frp grating platform

Safety is paramount in any industrial or commercial setting, and FRP grating platforms are designed with this in mind. They are available in various surfaces, including slip-resistant options, which enhance safety for personnel navigating the platforms. Furthermore, FRP materials are non-conductive, reducing the risk of electrical hazards in environments where electrical equipment is present. The combination of lightweight structure, durability, and safety features makes FRP grating an essential component for modern industrial designs.

Sustainability is another factor driving the adoption of FRP grating platforms. As industries become more environmentally conscious, the demand for materials that are not only durable but also sustainable is on the rise. FRP can be manufactured using recycled materials and is also recyclable at the end of its life cycle. This movement towards more sustainable practices is essential for companies aiming to reduce their environmental footprints and adhere to stricter regulations.

The versatility of FRP grating platforms means they can be customized to meet specific needs. Manufacturers offer a range of colors and dimensions, allowing businesses to design their platforms according to unique requirements or aesthetic preferences. Whether in a manufacturing plant, water treatment facility, or a scenic boardwalk, the adaptability of FRP grating makes it suitable for various applications.

In conclusion, FRP grating platforms represent a significant advancement in construction and industrial design. Their lightweight, corrosion-resistant, and customizable features offer numerous advantages over traditional materials, paving the way for widespread adoption across multiple sectors. As industries continue to prioritize safety, efficiency, and sustainability, FRP grating platforms will undoubtedly play a vital role in shaping the future of construction and infrastructure development. The journey of FRP technology is just beginning, and its impact on the industrial landscape continues to grow, marking it as a revolutionary material for years to come.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025