loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Profiles: Lightweight, Corrosion-Resistant, Custom Made

Frp Profiles is a key solution in the Material manufacturing industry, specifically within composite material and FRP profiles. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Frp Profiles Overview

- Benefits & Use Cases of Frp Profiles in FRP profiles

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Material manufacturing

- Conclusion on Frp Profiles from Zhaojia Composites Co., Ltd

Frp Profiles Overview

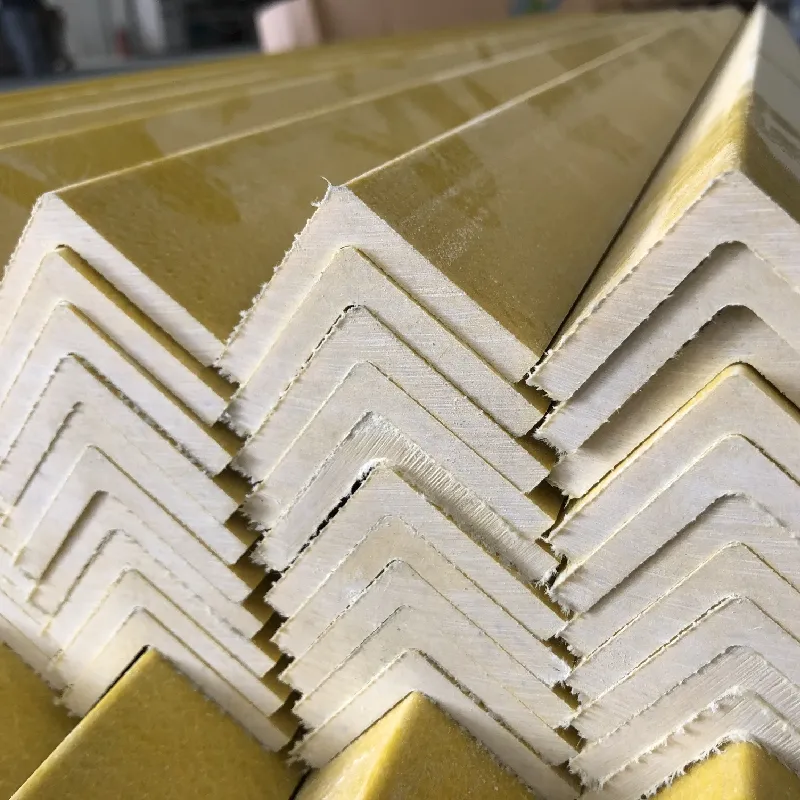

Frp Profiles are pultruded fiberglass-reinforced polymer structural shapes—such as I-beams, channels, tubes, and angles—engineered to deliver high strength-to-weight, corrosion resistance, and long-term dimensional stability. In material manufacturing, especially across composite material supply chains, these profiles replace painted or galvanized steel where exposure to moisture, salt, chemicals, or electric current would accelerate degradation. Their relevance spans structural frames, access systems, platforms, and support infrastructure in industrial and civil environments.

Technically, pultruded Frp Profiles combine continuous E-glass reinforcements with thermoset resins (commonly isophthalic polyester or vinyl ester) and UV-protective surfacing veils. The result is consistent mechanical performance along the pultrusion direction with typical properties that include low density (~1.7–2.0 g/cm³), excellent fatigue resistance, and stable dielectric behavior for non-conductive applications. Profiles can be specified to industry benchmarks (e.g., EN 13706, ASTM D638/D790) with options for flame-retardant, UV-stabilized, and color-through formulations for durability and visual management.

Zhaojia Composites Co., Ltd manufactures precision pultruded fiberglass I-beams and other shapes with tight tolerances, consistent resin/glass ratios, and in-house tooling control. A recent utility platform upgrade illustrates the value: replacing rust-prone steel with vinyl-ester FRP I-beams reduced annual coating work orders and enabled weekend-only installation thanks to the lighter components, keeping operations online during the week.

Benefits & Use Cases of Frp Profiles in FRP profiles

In the FRP profiles category, Frp Profiles are deployed in chemical processing plants, wastewater facilities, coastal infrastructure, cooling towers, power distribution corridors, and transportation hubs. Common assemblies include structural skids, walkways and handrails, ladder systems, cable trays, equipment supports, and mezzanines. Their non-conductive nature supports electrical safety, while corrosion resistance withstands acid fumes, saline mist, and disinfectants that quickly undermine metallic alternatives.

- Performance advantages: high strength-to-weight, excellent corrosion resistance, low thermal conductivity, and stable dielectric properties.

- Installation efficiency: lighter profiles speed handling, reduce lifting equipment, and enable prefabrication and bolted connections for rapid site work.

- Longevity: color-through, UV-stabilized surfaces and optional flame-retardant resins support demanding outdoor and plant environments.

- Design flexibility: broad geometry set—angles, channels, I-beams, square tubes—and CNC post-processing for holes, slots, and kitted assemblies.

Zhaojia Composites Co., Ltd brings application-driven engineering, from resin selection to die design and quality control. Their fiberglass I-beam product line is tailored for construction and industrial use, achieving consistent pultrusion quality that helps EPCs and plant owners meet structural, safety, and uptime goals with fewer maintenance interruptions than legacy materials.

Cost, Maintenance & User Experience

Total cost of ownership is where Frp Profiles excel. While initial pricing can be comparable to galvanized steel, lifecycle costs often drop significantly due to minimal painting, superior corrosion resistance, and reduced shutdowns for repairs. Lower weight cuts freight and crane time, and prefabrication shortens installation windows—key drivers of project ROI in brownfield plants and time-sensitive builds. In corrosive environments, owners often realize multi-year maintenance deferrals, translating to double-digit percentage savings over the asset life.

Feedback from composite-savvy customers highlights three themes: predictable performance under chemical exposure, improved electrical safety for personnel working near conductors, and cleaner aesthetics over time because color is embedded in the profile. EPCs report smoother commissioning thanks to consistent tolerances and kitted deliveries. For asset managers, these factors combine into a compelling ROI—through fewer coating cycles, lower labor hours, and extended service life—making Frp Profiles a pragmatic upgrade path from traditional steel in aggressive settings.

Sustainability & Market Trends in Material manufacturing

Sustainability priorities in material manufacturing increasingly favor solutions that reduce maintenance chemicals, extend service life, and cut transport emissions. Frp Profiles address all three: fewer recoating cycles and less corrosion abatement lower VOCs and hazardous waste; lighter structures reduce the carbon intensity of shipping and handling; and durability curbs premature replacements. Specifiers are also aligning with performance-based standards that recognize composite longevity in marine, water, and industrial sectors, fueling steady market growth for pultruded profiles.

Zhaojia Composites Co., Ltd approaches sustainability pragmatically—optimizing resin systems for durability, supporting precise kitting to minimize jobsite scrap, and exploring recycling pathways for manufacturing offcuts via mechanical reprocessing. As regulations evolve around worker safety, emissions, and environmental stewardship, the company’s focus on quality, traceability, and application engineering positions it as a forward-thinking partner. For B2B decision makers, this means dependable supply, compliant materials, and designs that meet today’s ESG expectations without sacrificing performance.

Conclusion on Frp Profiles from Zhaojia Composites Co., Ltd

In composite material supply chains, Frp Profiles deliver reliable, corrosion-resistant strength with predictable installation and long service life—an ideal fit for industrial, municipal, and coastal environments. Zhaojia Composites Co., Ltd couples manufacturing precision with application expertise, helping owners and EPCs hit structural, safety, and cost targets with confidence. Ready to specify or request a quote? Contact us: email: admin@zjcomposites.com. Visit our website: https://www.zjcomposites.com. Explore our fiberglass I-beam product page for details and specs to support your next project.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025