loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp structural members

Understanding FRP Structural Members Advantages and Applications

Fiber Reinforced Polymer (FRP) structural members have emerged as a significant innovation in construction and engineering, combining the benefits of lightweight materials with high strength and durability. These advanced composites are made by embedding fibers, such as glass, carbon, or aramid, within a polymer matrix. The result is a material that excels in various applications, particularly in environments that require resilience against moisture, chemicals, and corrosion.

One of the primary advantages of FRP structural members is their outstanding strength-to-weight ratio. Traditional materials like steel and concrete, while strong, can be cumbersome, leading to higher transportation and installation costs. In contrast, FRP members are significantly lighter, making them easier to handle and install. This characteristic is especially beneficial in projects where reducing the dead load is critical, such as in bridge construction or retrofitting old structures.

Understanding FRP Structural Members Advantages and Applications

Another significant benefit of FRP is its versatility in design and application. FRP members can be manufactured in various shapes and sizes, allowing engineers and architects to create innovative structures that might be challenging to achieve with traditional materials. For instance, the ability to mold FRP into complex geometries opens new avenues for aesthetic architectural elements while maintaining structural integrity.

frp structural members

The applications of FRP structural members are diverse. In civil engineering, they are increasingly used for reinforcing existing structures, providing a lightweight solution that enhances load-bearing capacity without substantial modifications to the original design. In addition, FRP can be found in the construction of new buildings, bridges, and tunnels where strength, weight, and resistance to environmental factors are paramount.

In the transport sector, FRP has become popular due to its application in railways and highways. Its lightweight nature contributes to improved fuel efficiency in transportation vehicles, as less energy is required to move lighter loads. Furthermore, construction techniques using FRP materials can lead to quicker project completions, minimizing disruption and maximizing efficiency.

However, it is essential to consider the limitations of FRP materials. While they exhibit superior resistance to corrosion, they may not perform well under extreme temperatures when compared to traditional materials. Furthermore, the initial cost of FRP can sometimes be higher due to the advanced manufacturing processes involved. Despite these drawbacks, the overall benefits often outweigh the negatives, particularly over the lifecycle of a project.

In conclusion, FRP structural members represent a significant advancement in the field of engineering and construction. Their remarkable strength-to-weight ratio, resistance to environmental degradation, and design versatility make them an attractive choice for various applications. As technology continues to evolve, it is likely that the use of FRP will expand further, paving the way for more sustainable and innovative construction solutions. With ongoing research and development, the full potential of FRP materials will continue to be realized, transforming our approach to building the infrastructure of the future.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

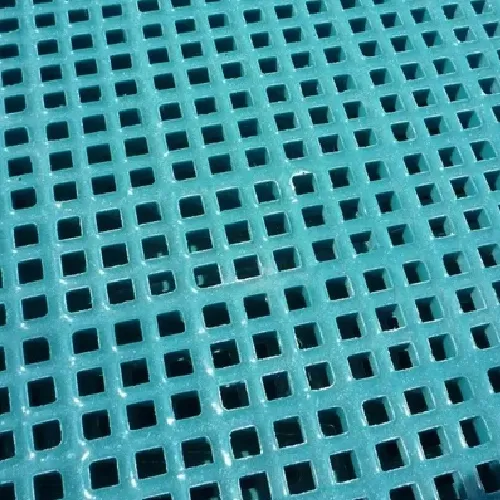

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025