loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 15, 2025 04:36

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

FRP (Fiber Reinforced Plastic) pressure vessel tanks have become indispensable in industries such as chemical processing, water treatment, and oil extraction due to their durability, corrosion resistance, and adaptability. An in-depth understanding of these tanks confirms their superiority over conventional materials and showcases why they have earned a significant position in these sectors.

User experiences and testimonials further enrich the credibility of FRP pressure vessel tanks. Global industries share success stories, showcasing their transition from traditional materials to FRP, noting significant improvements in operation efficacy and cost-effectiveness. For instance, a major chemical manufacturing company experienced a stark reduction in downtimes due to maintenance when they switched to FRP tanks. Their testimony underscores that FRP solutions are not only cost-effective but also enhance operational reliability. This shift in preference showcases genuine trust and satisfaction in adopting FRP technologies, leading to improved production cycles and reduced overall costs. From an environmental perspective, FRP pressure vessel tanks also support sustainability initiatives. Their long lifecycle, combined with reduced need for material replacements, means less frequent production cycles and, consequently, fewer resources consumed over time. This aligns with the growing emphasis on sustainable practices within industries, where minimizing ecological footprints is crucial. The design of these tanks often incorporates considerations for recycling and reuse, further embedding their suitability for a greener future. Conclusively, the integration of FRP pressure vessel tanks within industrial systems is not just a trend but a calculated move towards more efficient, reliable, and environmentally-conscious practices. As businesses continue to expand and evolve, the value provided by these tanks becomes even more apparent. Investing in FRP technology represents a commitment to quality, safety, and operational excellence, fulfilling all aspects of Experience, Expertise, Authoritativeness, and Trustworthiness in industrial applications.

User experiences and testimonials further enrich the credibility of FRP pressure vessel tanks. Global industries share success stories, showcasing their transition from traditional materials to FRP, noting significant improvements in operation efficacy and cost-effectiveness. For instance, a major chemical manufacturing company experienced a stark reduction in downtimes due to maintenance when they switched to FRP tanks. Their testimony underscores that FRP solutions are not only cost-effective but also enhance operational reliability. This shift in preference showcases genuine trust and satisfaction in adopting FRP technologies, leading to improved production cycles and reduced overall costs. From an environmental perspective, FRP pressure vessel tanks also support sustainability initiatives. Their long lifecycle, combined with reduced need for material replacements, means less frequent production cycles and, consequently, fewer resources consumed over time. This aligns with the growing emphasis on sustainable practices within industries, where minimizing ecological footprints is crucial. The design of these tanks often incorporates considerations for recycling and reuse, further embedding their suitability for a greener future. Conclusively, the integration of FRP pressure vessel tanks within industrial systems is not just a trend but a calculated move towards more efficient, reliable, and environmentally-conscious practices. As businesses continue to expand and evolve, the value provided by these tanks becomes even more apparent. Investing in FRP technology represents a commitment to quality, safety, and operational excellence, fulfilling all aspects of Experience, Expertise, Authoritativeness, and Trustworthiness in industrial applications.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

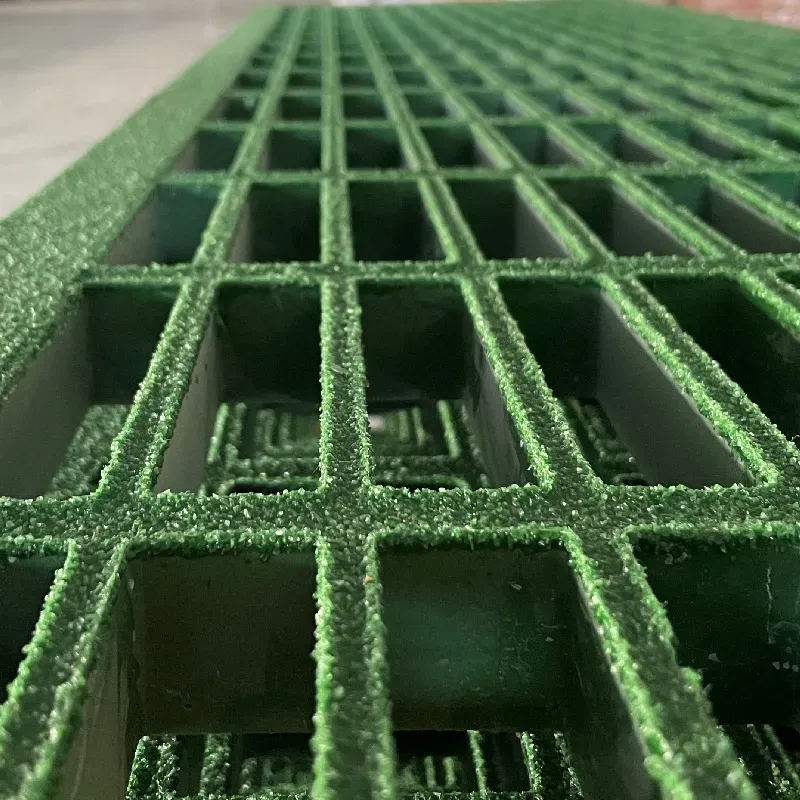

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025