loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 14, 2025 11:00

Back to list

frp micro mesh grating

Fiberglass bar grating has emerged as an indispensable solution in various industries due to its unique blend of durability, safety, and cost-effectiveness. Understanding these characteristics requires insight from both user experience and expert analysis, enabling industries to harness its full potential.

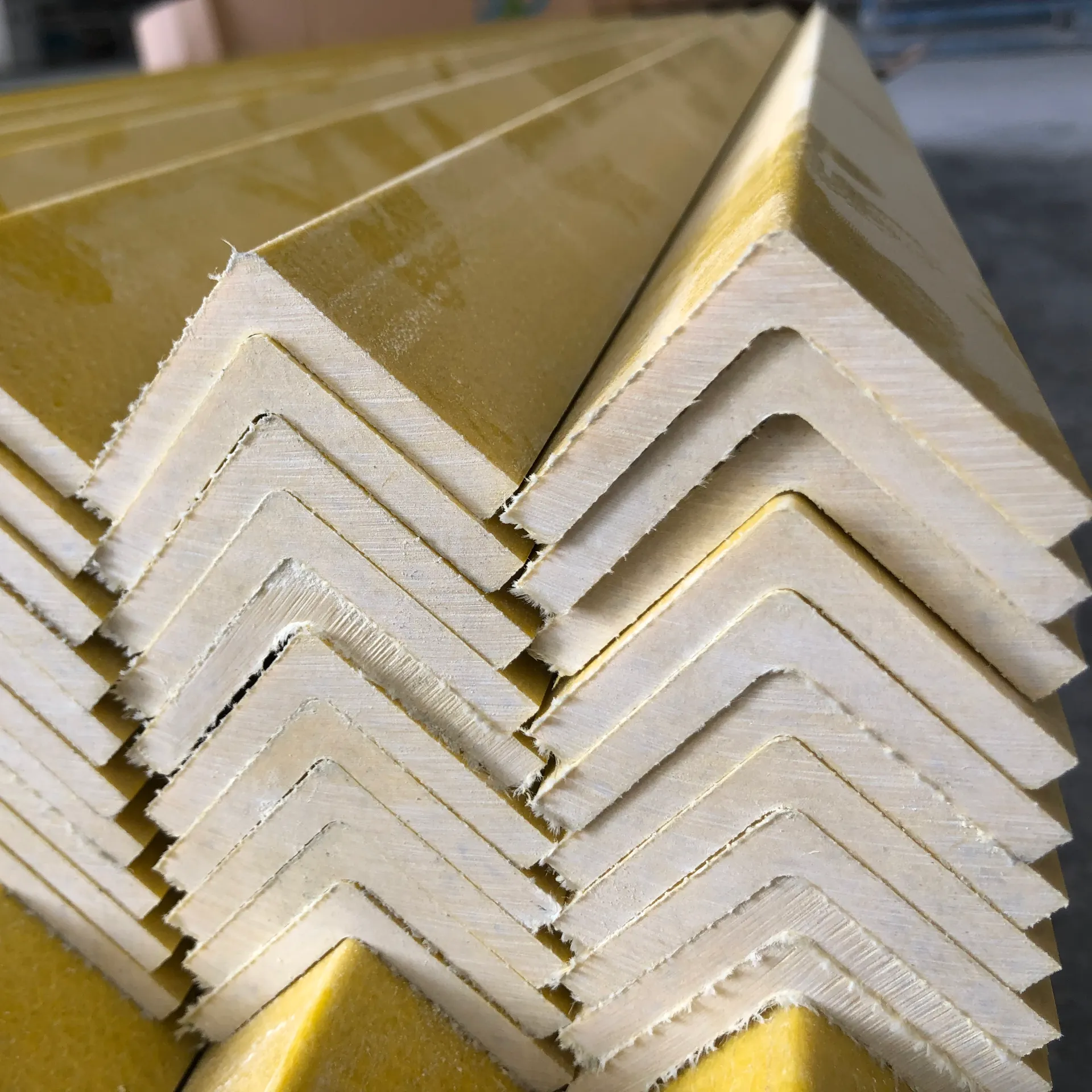

From an expertise perspective, the manufacturing process of fiberglass bar grating involves a thorough resin reinforcement technique. This process can be customized to meet specific industry requirements, offering variations such as molded or pultruded grating. Molded fiberglass bar gratings provide multidirectional strength and are suitable for applications requiring high impact resistance. On the other hand, pultruded gratings offer enhanced load-bearing capacity, perfect for spanning longer distances in infrastructure projects. Industry experts highlight the environmental benefits of fiberglass bar grating. With sustainability becoming a paramount concern, the recyclability of fiberglass materials positions it as a responsible choice for eco-conscious corporations. By adopting fiberglass alternatives, companies not only reduce their carbon footprint but also benefit from a product lifecycle that supports environmental responsibility. Trust in fiberglass bar grating is further solidified by compliance with international safety standards. Many manufacturers adhere to standards such as ASTM, ANSI, and ISO, providing assurance of product quality and performance. Clients often refer to certifications when selecting grating solutions, emphasizing the importance of verified compliance. Incorporating fiberglass bar grating into operations is a strategic decision that combines safety, efficiency, and sustainability. Industries worldwide are increasingly gravitating towards this innovative solution, driven by proven case studies and a growing body of expertise. By leveraging the distinct advantages of fiberglass bar grating, businesses can achieve operational excellence while prioritizing safety and environmental impact. This convergence of benefits marks fiberglass bar grating as a trusted component in the modern industrial landscape.

From an expertise perspective, the manufacturing process of fiberglass bar grating involves a thorough resin reinforcement technique. This process can be customized to meet specific industry requirements, offering variations such as molded or pultruded grating. Molded fiberglass bar gratings provide multidirectional strength and are suitable for applications requiring high impact resistance. On the other hand, pultruded gratings offer enhanced load-bearing capacity, perfect for spanning longer distances in infrastructure projects. Industry experts highlight the environmental benefits of fiberglass bar grating. With sustainability becoming a paramount concern, the recyclability of fiberglass materials positions it as a responsible choice for eco-conscious corporations. By adopting fiberglass alternatives, companies not only reduce their carbon footprint but also benefit from a product lifecycle that supports environmental responsibility. Trust in fiberglass bar grating is further solidified by compliance with international safety standards. Many manufacturers adhere to standards such as ASTM, ANSI, and ISO, providing assurance of product quality and performance. Clients often refer to certifications when selecting grating solutions, emphasizing the importance of verified compliance. Incorporating fiberglass bar grating into operations is a strategic decision that combines safety, efficiency, and sustainability. Industries worldwide are increasingly gravitating towards this innovative solution, driven by proven case studies and a growing body of expertise. By leveraging the distinct advantages of fiberglass bar grating, businesses can achieve operational excellence while prioritizing safety and environmental impact. This convergence of benefits marks fiberglass bar grating as a trusted component in the modern industrial landscape.

Share

Latest news

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025