loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

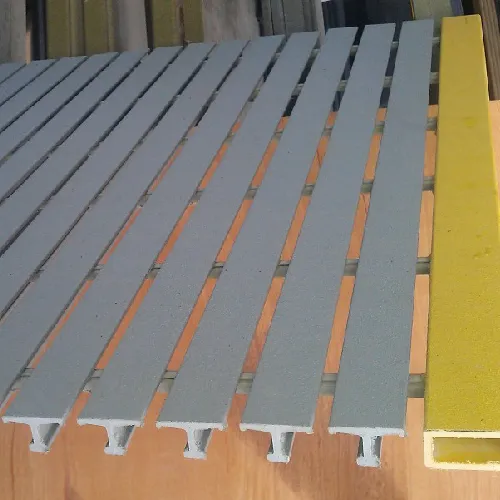

floor grating clamps

Understanding Floor Grating Clamps Importance, Types, and Applications

Floor grating clamps are essential components in the assembly and maintenance of floor grating systems. These systems are widely used in various industries, including construction, manufacturing, and warehousing, due to their safety, durability, and efficient drainage capabilities. This article explores the importance, types, and applications of floor grating clamps, highlighting their role in enhancing safety and performance.

Importance of Floor Grating Clamps

Floor grating serves as a critical element in industrial settings, providing safe walkways and platforms for workers while allowing for the passage of air, light, and water. However, to maintain their functionality and safety, grating panels must be securely fastened to prevent any accidental displacement. This is where floor grating clamps come into play.

Grating clamps are designed to hold grating panels in place, ensuring stability and preventing any movement that could lead to accidents. They provide a secure connection between the floor beams and the grating, which is essential for maintaining a safe walking surface. By preventing buckling or warping of the grating, these clamps also contribute to the longevity of the flooring system, reducing the need for frequent repairs or replacements.

Types of Floor Grating Clamps

There are several types of floor grating clamps available, each designed for specific applications and types of grating. The most common types include

1. Standard Clamps These are often made of steel or aluminum and are used for general applications in industrial environments. They offer a strong grip and are suitable for heavy-duty grating.

floor grating clamps

2. Screw Clamps Featuring a threaded mechanism, screw clamps provide a reliable and adjustable fastening solution. These clamps allow for easy installation and maintenance, making them ideal for grating systems that may require frequent adjustments.

3. Welded Clamps As the name suggests, welded clamps are permanently attached to the grating through a welding process. These clamps are often used in situations where maximum security is needed, offering excellent structural integrity.

4. Quick-Release Clamps Designed for systems that require quick access or modifications, quick-release clamps can be easily removed and reattached. They are particularly beneficial in maintenance environments where grating needs to be accessed frequently.

Applications of Floor Grating Clamps

The applications of floor grating clamps are diverse. In industrial facilities, they are used to secure grating panels in locations such as walkways, platforms, and machinery housing. In outdoor settings, grating clamps are critical for ensuring the stability of grating used in drainage systems to prevent flooding and water damage.

Additionally, floor grating clamps are used in areas that require slip-resistant surfaces, such as ramps and staircases. By ensuring that the grating is firmly secured, these clamps help prevent accidents in environments where spills or debris may pose a hazard.

In conclusion, floor grating clamps are a vital component in the assembly and maintenance of grating systems. Their role in enhancing safety and performance cannot be overstated. By understanding the types and applications of these clamps, industries can make informed decisions when selecting the right fastening solutions for their grating systems, ultimately ensuring a secure and functional work environment.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025