loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Mar . 05, 2025 02:26

Back to list

frp vessel for water treatment

Cartridge filter vessels play an indispensable role in numerous industries, serving as pivotal components in fluid filtration systems. Designed to offer superior filtration capabilities, these vessels house cartridge filters, which are the key to capturing unwanted particles and impurities, ensuring the purity and quality of the final product.

Authoritativeness in cartridge filter vessel manufacturing stems from rigorous research and continuous innovation. Leading manufacturers invest heavily in R&D, striving to improve performance metrics like flow rate and filtration accuracy. Collaborations with academic institutions often result in breakthroughs such as novel filtration media, which can offer higher dirt-holding capacities and longer life cycles. For businesses looking to optimize their filtration processes, aligning with manufacturers known for their authoritative research and industry certifications can be the difference between mediocre and outstanding product quality. Trustworthiness in the realm of cartridge filter vessels is earned through consistent performance and adherence to industry standards. Trusted manufacturers provide detailed documentation, including performance data and compliance certifications, ensuring that clients are well-informed. Furthermore, a reliable supplier will offer robust customer support, including expert consultations and maintenance services, enhancing the trust relationship. Companies are advised to review case studies and customer testimonials when selecting a supplier, as these provide insight into the real-world reliability and performance of the vessels offered. In conclusion, cartridge filter vessels are not merely components of a filtration system; they are the backbone of product quality assurance in various industries. Their role in ensuring cleanliness and safety is anchored in the principles of experience, expertise, authoritativeness, and trustworthiness. By choosing the right vessel, businesses can safeguard their production processes, enhance efficiency, and maintain compliance with industry regulations, ultimately leading to improved customer satisfaction and loyalty. Investing in a high-quality cartridge filter vessel is, therefore, investing in the future of the product itself.

Authoritativeness in cartridge filter vessel manufacturing stems from rigorous research and continuous innovation. Leading manufacturers invest heavily in R&D, striving to improve performance metrics like flow rate and filtration accuracy. Collaborations with academic institutions often result in breakthroughs such as novel filtration media, which can offer higher dirt-holding capacities and longer life cycles. For businesses looking to optimize their filtration processes, aligning with manufacturers known for their authoritative research and industry certifications can be the difference between mediocre and outstanding product quality. Trustworthiness in the realm of cartridge filter vessels is earned through consistent performance and adherence to industry standards. Trusted manufacturers provide detailed documentation, including performance data and compliance certifications, ensuring that clients are well-informed. Furthermore, a reliable supplier will offer robust customer support, including expert consultations and maintenance services, enhancing the trust relationship. Companies are advised to review case studies and customer testimonials when selecting a supplier, as these provide insight into the real-world reliability and performance of the vessels offered. In conclusion, cartridge filter vessels are not merely components of a filtration system; they are the backbone of product quality assurance in various industries. Their role in ensuring cleanliness and safety is anchored in the principles of experience, expertise, authoritativeness, and trustworthiness. By choosing the right vessel, businesses can safeguard their production processes, enhance efficiency, and maintain compliance with industry regulations, ultimately leading to improved customer satisfaction and loyalty. Investing in a high-quality cartridge filter vessel is, therefore, investing in the future of the product itself.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

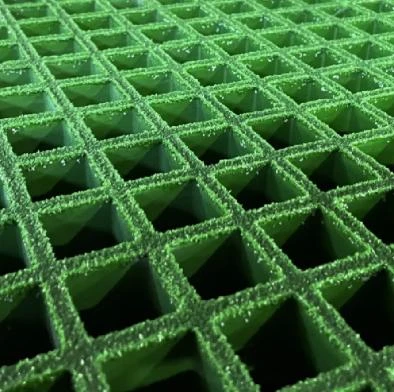

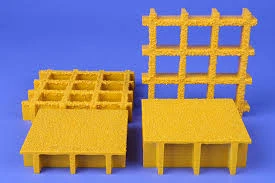

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025