loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

lut . 04, 2025 03:47

Back to list

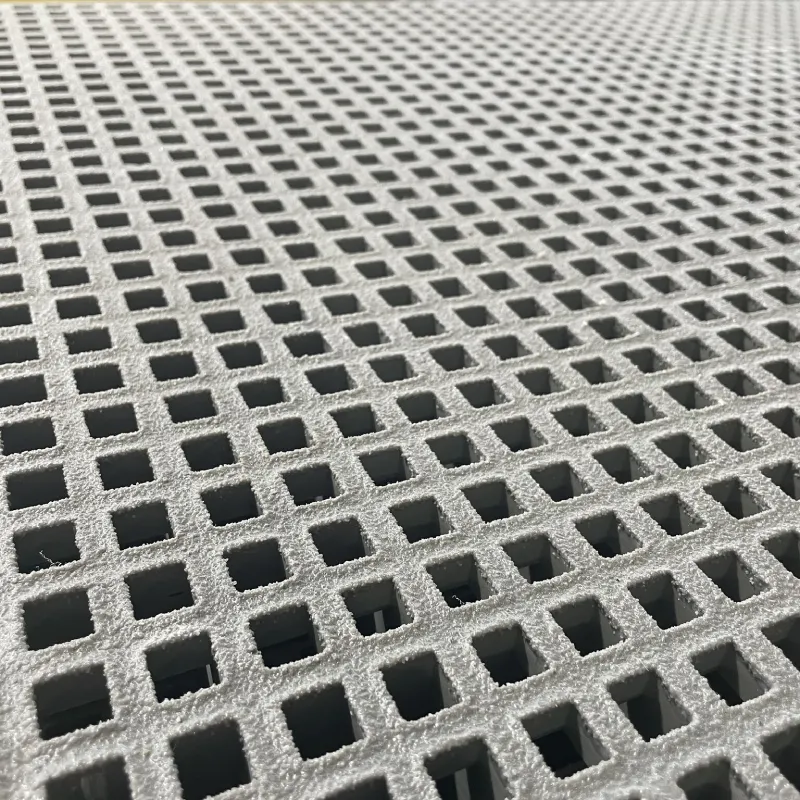

frp micro mesh grating

Grating wire mesh, an integral component in industrial and architectural applications, plays a crucial role in providing safety, security, and structural support. It is renowned for its durability, versatility, and strength. This article sheds light on the multifaceted uses of grating wire mesh, its manufacturing processes, and its value proposition, providing insights from industry experts and experienced users to ensure the content is both authoritative and trustworthy.

Industry leaders advocate for the adoption of grating wire mesh because of its conformity to rigorous safety standards. Certified products undergo exhaustive testing to ensure they can withstand extreme pressures and temperatures, offering peace of mind to businesses and communities alike. Compliance with international safety standards also underlines the authoritative standing of reputable manufacturers who continually innovate to improve product performance and environmental impact. Moreover, technological advancements in production techniques are making grating wire mesh more accessible and varied. Laser cutting and automated welding are just two methods increasing precision and efficiency, allowing for the production of highly customized designs without compromising structural integrity. These technological evolutionary steps are informed by both expertise and real experiences, ensuring the development of products that not only meet but exceed market expectations. Expertise in the field highlights that investing in quality grating wire mesh can lead to significant long-term savings. Their durability and minimal maintenance needs reduce operational costs over time. A project manager from a leading engineering consulting firm notes that although the initial investment might be higher compared to other materials, the extended lifespan and reliability offered by grating wire mesh often result in substantial cost benefits. For those considering grating wire mesh, trustworthiness in supplier choice is vital. Partnering with manufacturers and distributors renowned for their quality assurance practices and customer service can make a profound difference. Reliable suppliers not only provide superior products but also offer valuable guidance and support, ensuring that the chosen grating wire mesh aligns perfectly with project goals and specifications. In conclusion, the comprehensive benefits of grating wire mesh, from load-bearing efficiency to aesthetic flexibility, make it an indispensable material across diverse sectors. Its trusted use in projects worldwide speaks volumes about its versatility and dependability. For businesses and individuals keen on combining safety, sustainability, and strength, grating wire mesh is an unrivaled choice, backed by experienced professionals and evidence-based practices that ensure its continued relevance and application in the engineering and architectural domains.

Industry leaders advocate for the adoption of grating wire mesh because of its conformity to rigorous safety standards. Certified products undergo exhaustive testing to ensure they can withstand extreme pressures and temperatures, offering peace of mind to businesses and communities alike. Compliance with international safety standards also underlines the authoritative standing of reputable manufacturers who continually innovate to improve product performance and environmental impact. Moreover, technological advancements in production techniques are making grating wire mesh more accessible and varied. Laser cutting and automated welding are just two methods increasing precision and efficiency, allowing for the production of highly customized designs without compromising structural integrity. These technological evolutionary steps are informed by both expertise and real experiences, ensuring the development of products that not only meet but exceed market expectations. Expertise in the field highlights that investing in quality grating wire mesh can lead to significant long-term savings. Their durability and minimal maintenance needs reduce operational costs over time. A project manager from a leading engineering consulting firm notes that although the initial investment might be higher compared to other materials, the extended lifespan and reliability offered by grating wire mesh often result in substantial cost benefits. For those considering grating wire mesh, trustworthiness in supplier choice is vital. Partnering with manufacturers and distributors renowned for their quality assurance practices and customer service can make a profound difference. Reliable suppliers not only provide superior products but also offer valuable guidance and support, ensuring that the chosen grating wire mesh aligns perfectly with project goals and specifications. In conclusion, the comprehensive benefits of grating wire mesh, from load-bearing efficiency to aesthetic flexibility, make it an indispensable material across diverse sectors. Its trusted use in projects worldwide speaks volumes about its versatility and dependability. For businesses and individuals keen on combining safety, sustainability, and strength, grating wire mesh is an unrivaled choice, backed by experienced professionals and evidence-based practices that ensure its continued relevance and application in the engineering and architectural domains.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025