loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP grating panels in temporary disaster-relief architecture

When disaster strikes—be it an earthquake, flood, hurricane, or conflict—the immediate priority is to save lives and provide urgent, safe shelter for displaced populations. The architecture of crisis is a race against time, demanding solutions that are not only swift to deploy but also durable, safe, and adaptable to the most challenging environments. In this critical field, innovation in materials science is paving the way for more effective and humane relief efforts. Leading this charge are advanced composite materials, specifically FRP grating panels, which are redefining the very foundations of temporary disaster-relief structures. This article explores how these remarkable products are creating safer, more resilient spaces where they are needed most.

The Unmatched Advantages of FRP Grating in Crisis Scenarios

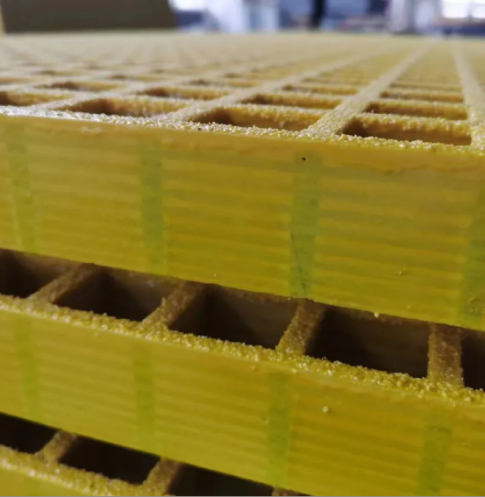

In the chaotic aftermath of a disaster, infrastructure is often decimated. Traditional building materials like wood, steel, and concrete can be too heavy, slow to assemble, or susceptible to the very elements that caused the destruction. This is where FRP grating demonstrates its profound value. Composed of a matrix of glass fibers embedded in a corrosion-resistant polymer resin, this material is engineered for performance under pressure.

The core advantages that make FRP grating ideal for relief efforts are detailed in the table below:

|

Advantage |

Description |

|

Durability |

Unlike traditional grating materials, Fiberglass reinforced plastic grating does not suffer from corrosion, rust or rot. It is also unaffected by many chemicals and suitable for submerged environments. |

|

Safety |

It is not just a products longevity that needs to be a consideration, safety needs to be included. FRP grating comes in a range of non-slip surfaces are available to ensure that even when wet, there will be no slips. ZJ Composites FRP Grating also carries a flame-spread index (rating) of 25 or less when tested in accordance with the ASTME-84 standard, while also meeting the ASTM D-635 extinguishing requirements. |

|

Strength and Stability |

An excellent feature of fiberglass reinforced plastic grating is it ability to absorb impacts that would damage and permanently deform steel and aluminum grating. The FRP grating will retain its original shape. |

|

Maintenance |

Ongoing maintenance of traditional materials like steel, cost dramatically increase the lifecycle cost of a project. Even with the ongoing maintenance the steel grating will still need to be replaced far in advance of its FRP equivalent. FRP grating is virtually maintenance free. |

These inherent properties translate directly to life-saving benefits in a relief camp. The non-slip surface is crucial on muddy, wet ground, preventing injuries among survivors and aid workers. Its fire-resistant nature is a critical safety feature in densely populated temporary settlements where the risk of fire is high. Furthermore, its resistance to rot and corrosion means that structures can withstand prolonged exposure to the elements, from torrential rains to coastal salt spray, without degrading, ensuring a safe haven for as long as it is needed.

Enhancing Safety and Ventilation with FRP Micro Mesh Grating

While standard FRP grating panels form excellent flooring and pathways, certain situations demand an even finer solution. This is where FRP micro mesh grating comes into its own. Characterized by its tightly spaced bars, this variant offers a significantly smaller open area, providing a unique set of benefits for specialized applications within a relief camp.

One of the most critical uses for FRP micro mesh grating is in medical triage and sanitation areas. In field hospitals and washing facilities, hygiene is paramount. The fine mesh prevents small items, such as medical instruments or personal effects, from falling through, while still allowing liquids and waste to drain away efficiently. This helps maintain a cleaner, more sterile environment, reducing the risk of infection and disease outbreak. Additionally, the solid footing it provides is essential for medical professionals who need to move quickly and confidently.

Beyond hygiene, FRP micro mesh grating is an excellent choice for perimeter fencing, guardrails, and protective screens. Its tight grid offers a physical barrier without creating a visual one, maintaining an open feel while ensuring security. It also provides superior debris containment and can be used to create safe, elevated walkways over unstable or sensitive ground, combining the strength of FRP grating with the precision required for more delicate operations.

The Practical Deployment of FRP Grating Panels for Rapid Shelter

The theoretical benefits of a material mean little if it cannot be deployed swiftly and efficiently in a crisis. This is the ultimate strength of FRP grating panels. Their design and manufacturing are geared towards rapid assembly with minimal tools and labor, a crucial factor when every minute counts.

FRP grating panels are remarkably lightweight. A single worker can easily carry a large panel, eliminating the need for heavy lifting machinery, which is often unavailable in disaster zones. This lightweight nature also significantly reduces transportation costs, allowing more aid to be shipped for the same budget. Upon arrival, their modularity shines. The panels are typically manufactured with standard dimensions and can be quickly cut to size on-site with simple tools. They are then secured into place using a variety of clamping systems or molded-in connectors, forming stable floors, ramps, and platforms in a matter of hours, not days.

This rapid deployment capability allows for the immediate establishment of essential infrastructure: raised sleeping platforms to protect survivors from damp ground, stable and safe flooring for communal kitchens and dining areas, durable walkways that turn muddy quagmires into passable routes, and secure foundations for temporary storage warehouses. The versatility of FRP grating panels means they can be repurposed as needs evolve, making them a truly dynamic asset in the fluid environment of a disaster relief operation.

FAQs About FRP Grating Panels

As you consider the best solutions for your relief projects or infrastructure needs, you may have some specific questions. Here, we address some of the most common queries about FRP grating panels and their specialized variants.

What are the key advantages of FRP grating over steel?

The primary advantages are corrosion resistance, lightweight properties, and minimal maintenance. Unlike steel, FRP grating will not rust, even when constantly exposed to water, chemicals, or salt air. It weighs up to 70% less than steel, making transport and installation far easier and cheaper. Finally, it requires no painting or galvanizing, saving significant time and resources over its long lifespan.

How does FRP micro mesh grating improve safety?

FRP micro mesh grating enhances safety by providing a superior non-slip surface with smaller openings. This prevents tripping hazards and ensures secure footing in wet conditions. Its fine mesh also stops small objects from falling through, which is critical in medical and kitchen areas, and can be used to create secure barriers without the need for solid, heavy walls.

Are FRP grating panels strong enough for heavy equipment?

Absolutely. FRP grating panels are engineered for high load-bearing capacity. Their unique construction allows them to absorb impact and resist permanent deformation, often outperforming aluminum in dynamic load situations. For projects involving heavy vehicle traffic or machinery, specific, high-strength profiles can be recommended and supplied to meet the exact structural requirements.

Can FRP grating be customized for specific project needs?

Yes, customization is a key strength. From panel size and grid pattern to resin type for specific chemical resistances and color, FRP grating panels can be tailored to your project. This ensures optimal performance, whether you need the standard grid for walkways or the specialized FRP micro mesh grating for sanitary applications.

Why is ZJ Composites a trusted partner for FRP grating?

ZJ Composites operates with a foundational belief that product quality is the bedrock of enterprise development. Our modern, scientific management model, backed by perfect testing equipment and strong technical support, ensures every sheet of FRP grating meets rigorous standards. We have built our customer service team with professionals who have overseas experience, ensuring clear communication and an ultimate after-sales service experience. We are committed to providing optimal solutions and achieving a win-win situation through strict quality and thoughtful service, striving to raise the bar with every client interaction.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025