loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

High-Strength Fiberglass Treads for Stairs Durable Fiberglass Grating Stair Treads Solutions

- Introduction to fiberglass treads

and their significance in modern infrastructure. - Technical advancements and key performance features of fiberglass stair treads.

- Comparative analysis of top manufacturers, highlighting strengths and weaknesses.

- Customization options available for fiberglass grating stair treads in various sectors.

- In-depth review of practical applications and industry case studies.

- Maintenance tips and best practices to maximize durability.

- Conclusion emphasizing the value of fiberglass treads in demanding environments.

(fiberglass treads)

Introduction: Why Fiberglass Treads Define Modern Safety Standards

In today’s engineering and architectural landscape, fiberglass treads have become a cornerstone for safe, long-lasting, and efficient walking surfaces. Unlike traditional steel or concrete steps, fiberglass treads are gaining widespread recognition for superior performance across sectors such as manufacturing, transport, water treatment, and construction. But what’s driving this migration? The combined demand for slip resistance, corrosion resistance, and ease of installation, along with proven cost-effectiveness, sets fiberglass stair treads apart from older alternatives. Global studies indicate that over 70% of leading facilities managers are shifting towards composite materials for critical infrastructure upgrades, underlining a trend that’s only gaining momentum.

Advanced Technical Features of Fiberglass Stair Treads

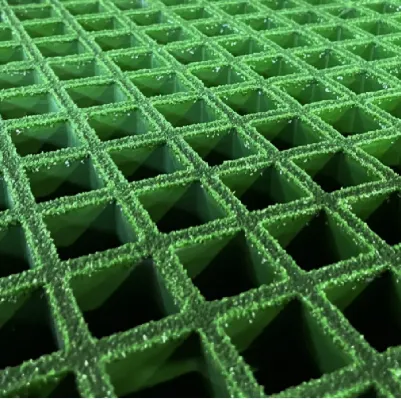

Technological innovation is at the heart of fiberglass stair treads’ rising popularity. Their high glass fiber content—typically between 65–70% by weight—yields outstanding mechanical strength without the density of metals. Coated with durable resin matrices, these treads surpass traditional materials with a service life exceeding 30 years under typical industrial loads. Slip resistance is enhanced through patterned surfaces, achieving coefficient of friction values up to 0.8 in wet conditions (well above safety thresholds for OSHA and ADA compliance). Furthermore, fire retardancy ratings such as ASTM E84 Class 1 and UV stability add layers of safety and longevity, making fiberglass grating stair treads an intelligent choice wherever exposure and hazard risks are high.

Manufacturer Comparison: Performance, Price, and Support

Choosing between global and regional suppliers is pivotal. The following table contrasts leading manufacturers on vital performance metrics:

| Manufacturer | Glass Content (%) | Warranty (Years) | Price/ft2 (USD) | Lead Time (Weeks) | Certifications | Technical Support |

|---|---|---|---|---|---|---|

| Fibra-Tech | 70 | 25 | 32.00 | 4 | ISO 9001, ASTM E84 | 24/7 Hotline, On-site training |

| GrateSafe Inc. | 65 | 20 | 28.50 | 6 | ASTM E84, UL94 | Email support |

| StairGuard Composites | 68 | 22 | 30.00 | 5 | ISO 14001, EN 13501 | Phone, Online resources |

| EcoStep Global | 72 | 30 | 34.50 | 7 | ASTM E84, REACH | Dedicated project manager |

A close look at these metrics reveals that while EcoStep Global commands a premium, it delivers the highest glass content and longest warranty, which is crucial for high-risk facilities. Fibra-Tech and StairGuard offer a balanced proposition with reasonable pricing, widely accepted certifications, and comprehensive technical support.

Customization: Engineered Fiberglass Grating Stair Treads Solutions

Flexibility is a defining attribute of fiberglass grating stair treads. Manufacturers now offer extensive customization to meet complex project requirements. Common variables include mesh size (19mm or 38mm open grid), tread width & depth (up to 1200mm wide), and surface grits (medium or coarse for extreme slip resistance). Color coding in line with safety standards—yellow, black, gray, or custom shades—can be specified for visibility and branding. For sectors handling chemical processing, resin selection is critical: vinyl ester resins offer top-tier chemical resistance for pH extremes, while orthophthalic resin provides economic balance for general use.

- Load capacity: Custom-engineered for up to 3000kg/m2

- Cut-to-fit service: Minimizes site installation time and errors

- Embedded nosings: High-visibility safety enhancements

- Inbuilt fixings: Simplifies anchoring, suitable for retrofits

The ability to tailor solutions, from rapid prototyping to serial production, makes these treads ideal for sectors seeking both safety assurance and project-specific performance.

Real-World Case Studies: Fiberglass Tread Applications Across Industries

The versatility of fiberglass stair treads shines in a variety of demanding environments. Here are two industry-leading examples:

1. Municipal Water Treatment Facility, Michigan, USA- Challenge: Replace corroded steel steps exposed to chlorine and constant moisture.

- Solution: Installation of 250 linear meters of fiberglass grating stair treads with anti-slip surface and yellow nosings.

- Outcome: Maintenance costs reduced by 85% over 5 years; no step failures or safety incidents reported.

- Challenge: Upgrade walkway safety in wet conditions; target zero downtime.

- Solution: 1300 custom-cut fiberglass stair treads; traffic gray surface for discreet integration.

- Outcome: Slip-related accidents down to zero for three years. Surveyed users rated comfort and grip 9.5/10 on average.

These case studies confirm the transformational safety and operational savings achieved by shifting to composites over legacy materials.

Maintenance & Long-Term Performance: Extending Product Lifespan

Proper care extends the operational life of fiberglass treads well beyond the industry standard. Routine cleaning with mild alkaline detergents prevents grime accumulation and preserves slip-resistant surfaces. Inspections every six to twelve months—especially in chemical exposure environments—help intercept early wear or impact damage. Unlike steel, fiberglass requires neither painting nor galvanizing, saving both labor and material costs over the product lifecycle. If replacement is eventually required, modular designs allow for swift, localized intervention without shutdowns. Environmental lifecycle studies estimate a 25–40% cost reduction for owners who implement scheduled maintenance routines over reactive repairs.

Conclusion: Fiberglass Treads Deliver Proven Value in Demanding Applications

As the evidence shows, fiberglass treads present a compelling combination of strength, adaptability, and longevity—attributes demanded by modern infrastructure. With rising industry expectations for safety, asset reliability, and sustainability, the shift towards high-performance fiberglass stair treads is driven not just by technical merit but also by clear business returns. Facilities worldwide are achieving tangible benefits: fewer accidents, dramatically lower maintenance expenses, and flexible specification to unique site challenges. For any organization striving for operational excellence in harsh or high-traffic settings, adopting composite grating stair treads is a forward-thinking investment with proven ROI and transformative results.

(fiberglass treads)

FAQS on fiberglass treads

Q: What are fiberglass treads?

A: Fiberglass treads are durable, non-corrosive platforms made from reinforced fiberglass. They are commonly used on stairs and walkways for added safety. Their non-slip surface makes them ideal for industrial and commercial settings.

Q: What are the benefits of fiberglass stair treads?

A: Fiberglass stair treads provide excellent slip resistance and durability. They are lightweight, easy to install, and require minimal maintenance. Additionally, they resist corrosion, making them suitable for harsh environments.

Q: How do fiberglass grating stair treads differ from regular stair treads?

A: Fiberglass grating stair treads incorporate an open-grid design for better drainage and slip resistance. This makes them particularly useful in wet or oily environments. They also offer the same strength and corrosion resistance as standard fiberglass treads.

Q: Where are fiberglass treads commonly installed?

A: Fiberglass treads are widely used in industrial, commercial, and marine environments. They are popular on catwalks, stairs, and platforms because of their slip resistance and longevity. Their rust-proof properties make them ideal for outdoor or moist areas.

Q: Are fiberglass stair treads easy to maintain?

A: Yes, fiberglass stair treads require minimal maintenance compared to metal or wood alternatives. They resist staining, rust, and corrosion, needing only occasional cleaning. This adds to their long-term value and reliability.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025