loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

pentair frp vessels

Pentair FRP Vessels A Comprehensive Overview

In the realm of water treatment and filtration systems, the importance of using high-quality vessels cannot be overstated. One of the leading providers in this field is Pentair, known for its innovative solutions that cater to various industrial and municipal needs. Among its offerings, Fiber-Reinforced Plastic (FRP) vessels stand out due to their numerous advantages over traditional materials. This article explores Pentair FRP vessels, their characteristics, applications, and the benefits they bring to the industries they serve.

What are FRP Vessels?

Fiber-Reinforced Plastic vessels are composite structures that combine plastic materials with reinforcing fibers, typically glass or carbon fibers. This combination results in a lightweight yet incredibly strong product that is resistant to corrosion and can withstand a variety of environmental conditions. Pentair has leveraged this technology to design FRP vessels that are not only durable and reliable but also versatile for different applications.

Characteristics of Pentair FRP Vessels

1. Corrosion Resistance One of the most significant advantages of Pentair FRP vessels is their resistance to corrosion. Unlike traditional steel or metal tanks, FRP vessels do not rust or corrode, even when exposed to harsh chemicals and environmental factors. This property makes them ideal for use in water treatment plants and chemical processing facilities.

2. Lightweight and Strong FRP vessels are considerably lighter than their metal counterparts. This feature not only simplifies the installation process but also allows for easier transport and handling. Despite their lightweight nature, these vessels maintain a high strength-to-weight ratio, which ensures durability and longevity.

3. Low Thermal Conductivity Pentair FRP vessels exhibit low thermal conductivity, which means they are less likely to experience thermal expansion and contraction. This characteristic is critical in applications where temperature fluctuations occur, as it helps maintain the integrity of the vessel.

4. Customizable Sizes and Shapes Pentair offers FRP vessels in various sizes and configurations, allowing for customization to meet specific operational requirements. This flexibility is particularly beneficial for industries with unique spatial constraints or specialized processes.

Applications of Pentair FRP Vessels

Pentair FRP vessels find applications across several industries, including

pentair frp vessels

- Water Treatment In municipal and industrial water treatment processes, FRP vessels are used for filtration, softening, and chemical dosing. Their corrosion resistance ensures longer service life, reducing the need for frequent replacements.

- Chemical Processing In the chemical industry, where corrosive substances are prevalent, FRP vessels provide a safe solution for storing and transporting chemicals. Their ability to withstand harsh conditions makes them a preferred choice for chemical reactors and storage tanks.

- Food and Beverage The food and beverage industry requires equipment that meets strict safety and health standards. Pentair FRP vessels comply with these regulations and are used for water filtration and ingredient mixing.

- Oil and Gas In the oil and gas sector, FRP vessels are employed for a variety of applications, including wastewater treatment and chemical storage, owing to their robustness and resistance to chemical agents.

Benefits of Using Pentair FRP Vessels

1. Cost-Effectiveness While the initial investment in FRP vessels may be higher than traditional materials, their longevity and reduced maintenance costs lead to significant savings over time. This makes them a cost-effective solution in the long run.

2. Environmental Impact With a focus on sustainability, Pentair’s FRP vessels are designed to minimize environmental impact. Their durability ensures less frequent replacements, which translates to reduced material waste.

3. Innovative Design Pentair continuously innovates in vessel design to enhance performance and efficiency. Features like advanced surface finishes improve flow rates and reduce energy costs in water treatment applications.

4. Safety The lightweight nature of FRP vessels also contributes to safety, as there is less risk of injury during installation or maintenance due to heavy lifting.

Conclusion

Pentair FRP vessels represent a significant advancement in materials used for water treatment and other industrial applications. Their unique properties offer numerous advantages, including corrosion resistance, reduced weight, and customized solutions. As industries continue to seek efficient and sustainable options, Pentair’s commitment to innovation ensures that their FRP vessels remain at the forefront of technology, providing reliable performance for years to come. Regardless of the application, the benefits of using Pentair FRP vessels are clear, making them an excellent choice for various sectors.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

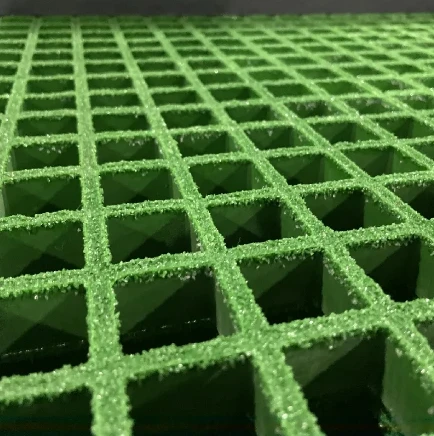

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025