loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

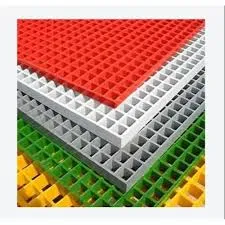

Innovative Moulded Gratings for Enhanced Durability and Aesthetic Appeal in Various Applications

The Advantages and Applications of Moulded Gratings

Moulded gratings are an innovative and versatile solution for a wide range of applications, showcasing impressive strength, durability, and resistance to corrosion. Their design and manufacturing process allow for an array of uses across various industries, making them a vital component in modern infrastructure. In this article, we will explore what moulded gratings are, their benefits, and the diverse applications they serve.

Moulded gratings are made from fibreglass reinforced plastic (FRP) through a process that involves the moulding of resin and reinforcing materials. This method creates a solid, durable product that is both lightweight and easy to install. Their non-metallic nature means that moulded gratings are not only resistant to rust and corrosion, but they also provide excellent electrical insulation properties. This makes them particularly useful in environments where moisture, chemicals, or electrical hazards are present.

One of the primary benefits of moulded gratings is their strength-to-weight ratio

. Despite being lightweight, they can bear significant loads, making them suitable for heavy-duty applications. Their inherent strength reduces the need for extensive support structures, resulting in cost savings during installation and maintenance. Additionally, moulded gratings can be fabricated in various sizes, thicknesses, and load ratings to meet specific project requirements.moulded gratings

Another significant advantage is their slip-resistant surface, which enhances safety in workplaces and public spaces. With their grooved or textured surfaces, moulded gratings effectively reduce the risk of slips and falls, making them ideal for pedestrian walkways, industrial flooring, and other high-traffic areas. Moreover, their design allows for effective drainage, preventing the accumulation of water or other liquids that can create hazardous conditions.

Moulded gratings find their applications across numerous sectors including industrial, commercial, and municipal environments. In the chemical processing and wastewater treatment industries, for instance, the corrosion resistance of moulded gratings makes them the preferred choice. They stand up to harsh chemicals and environments, providing a long-lasting solution that reduces downtime and replacement costs. In the oil and gas sector, these gratings are used in refineries and on offshore platforms, where both weight savings and resistance to harsh marine environments are crucial.

Additionally, moulded gratings are increasingly popular in architectural applications. Their aesthetic appeal can enhance the design of outdoor spaces, while their practicality ensures that they meet safety and functional requirements. They can be found in parks, stadiums, and retail environments, seamlessly blending into the surroundings while providing reliable performance.

In conclusion, moulded gratings offer an unbeatable combination of strength, durability, safety, and versatility, making them an essential component in a wide range of applications. Their resistance to corrosion, slip hazards, and their lightweight nature provide substantial advantages in various industries, ensuring that they will continue to be a valuable resource in the world of construction and infrastructure. As industries evolve and the demand for efficient, durable building materials increases, the role of moulded gratings is likely to expand even further.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025