loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

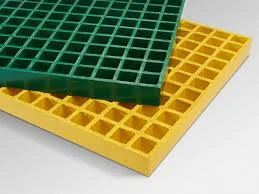

Innovative GRP Grating Solutions for Enhanced Durability and Safety in Various Applications

Exploring GRP Grating Systems Applications and Benefits

Glass Reinforced Plastic (GRP), commonly known as fiberglass, is a material that has garnered significant attention in various industrial applications due to its strength, durability, and lightweight properties. Among the myriad of applications, GRP grating systems stand out for their versatility and robustness. This article will delve into what GRP grating systems are, their benefits, applications, and the future of this innovative technology.

What are GRP Grating Systems?

GRP grating systems are composite materials made from a mixture of fiberglass and resin, which is molded into a grid-like structure. This structure is designed to provide a strong, slip-resistant walking surface that can be utilized in various environments. GRP grating is often preferred over traditional materials such as steel or wood, particularly in applications where weight and resistance to environmental factors are critical.

Key Benefits of GRP Grating Systems

1. Corrosion Resistance One of the most significant advantages of GRP grating systems is their excellent corrosion resistance. Unlike metals, GRP does not rust or corrode when exposed to moisture, chemicals, or saltwater, making it an ideal choice for marine and industrial environments.

2. Lightweight GRP is considerably lighter than steel, allowing for easier handling, installation, and transportation. This characteristic also leads to reduced structural support requirements, which can lower overall project costs.

3. Durability GRP grating is designed to withstand heavy loads and impacts, providing long-lasting performance. With proper maintenance, these systems can last for decades, making them a cost-effective solution over time.

4. Slip Resistance Safety is paramount in industrial settings, and GRP grating systems are engineered to offer superior slip resistance. The surfaces can be textured to enhance grip, reducing the risk of accidents.

5. Aesthetics GRP grating systems come in various colors and styles, allowing for customization that can blend with the visual aspects of the environment. This versatility makes them suitable for both functional and aesthetic applications.

6. Fire Resistance Many GRP materials are treated to be fire-resistant, making them suitable for applications in environments where fire safety is a concern, such as chemical plants and manufacturing facilities.

Applications of GRP Grating Systems

grp grating systems

Given their numerous advantages, GRP grating systems are widely used across several sectors. Some common applications include

- Industrial Flooring GRP grating provides a reliable and durable flooring solution for factories, warehouses, and processing plants, particularly in areas where chemical exposure is common.

- Walkways and Platforms These systems are commonly utilized for walkways and access platforms, providing safe passage in both indoor and outdoor environments, including parks and pedestrian areas.

- Marine Applications The corrosion resistance of GRP makes it an ideal choice for docks, piers, and other marine infrastructure, significantly reducing maintenance costs associated with traditional materials.

- Wastewater Treatment Plants GRP grating is frequently used in wastewater treatment facilities due to its resistance to harsh chemicals and prolonged exposure to water.

- Access Covers and Trench Grating GRP is employed for access covers and trench grating systems, offering safe and efficient access while effectively managing stormwater and drainage systems.

The Future of GRP Grating Systems

As industries continue to focus on sustainability, GRP grating systems are likely to see increased popularity due to their eco-friendly properties. The production of GRP often utilizes recycled materials, and its long life cycle contributes to reducing waste and lowering the carbon footprint.

Furthermore, advancements in manufacturing technologies will likely improve the performance and aesthetic options of GRP grating systems. Innovations such as integrated sensors for maintenance monitoring or enhancements in fire-resistant materials will expand their applications even further.

Conclusion

In summary, GRP grating systems represent a significant advancement in material technology, providing a durable, lightweight, and versatile solution for a variety of applications. As industries continue to seek out robust and sustainable options, GRP grating systems stand out as a reliable choice for enhancing safety and efficiency across various sectors. Embracing these systems will undoubtedly pave the way for innovative applications that address the evolving needs of modern infrastructure.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025