loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Louvers Designed for Improved Airflow in Cooling Towers

FRP Louvers for Cooling Towers Enhancing Efficiency and Durability

Cooling towers play a crucial role in various industrial and commercial applications by dissipating heat from processes or HVAC systems. To maximize their performance, the design features and materials used in cooling towers are of utmost importance. One such critical component is the louver, which aids in controlling airflow while minimizing water loss. Fiberglass Reinforced Plastic (FRP) louvers have gained popularity among engineers and facility managers for their superior attributes. This article explores the benefits and applications of FRP louvers in cooling towers.

Understanding FRP Louvers

Fiberglass Reinforced Plastic (FRP) is a composite material made of a polymer matrix reinforced with fiberglass. The incorporation of fiberglass enhances the strength and durability of the plastic, making it an ideal material for various industrial applications, including cooling towers. FRP louvers are specifically designed to enhance airflow, reduce heat, and prevent water loss. They serve several functions within a cooling tower, including directing airflow, reducing wind load, and preventing light entry, all of which significantly contribute to the overall efficiency of the cooling process.

Advantages of FRP Louvers

1. Corrosion Resistance One of the most significant benefits of FRP louvers is their resistance to corrosion. Cooling towers are often exposed to harsh operating environments, including moisture, chemicals, and extreme temperatures. Unlike traditional materials such as wood, aluminum, or steel, FRP does not rust or corrode over time, ensuring a longer lifespan and reduced maintenance costs.

2. Lightweight FRP louvers are considerably lighter than their metal counterparts, making them easier to handle and install. This lightweight property also reduces the overall structural load on the cooling tower, allowing for more flexible designs and reduced material costs in other components.

3. High Strength-to-Weight Ratio Despite being lightweight, FRP louvers possess a high strength-to-weight ratio. This makes them resistant to deformation under stress, ensuring they can withstand the mechanical and environmental challenges often faced by cooling towers.

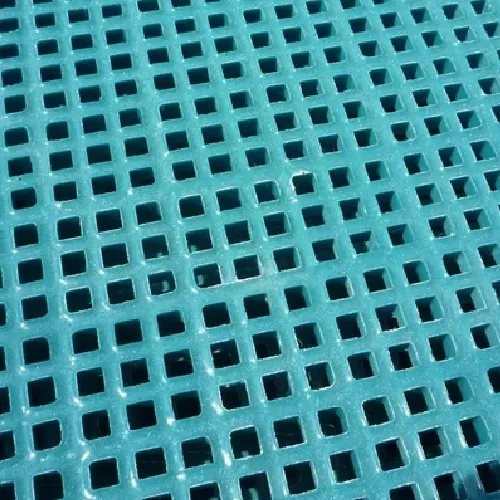

frp louvers for cooling tower

4. UV Stability FRP materials can be formulated to resist UV degradation, making them suitable for outdoor environments. This attribute is essential for cooling towers exposed to sunlight, where prolonged exposure can lead to material breakdown in traditional materials.

5. Customizability FRP louvers can be manufactured in various shapes and sizes to meet specific design requirements. They can be molded into intricate designs, allowing for better airflow dynamics, thus optimizing the cooling performance of the tower.

6. Cost-Effectiveness Over time, the benefits of using FRP louvers significantly outweigh the initial investment. The longevity and low maintenance requirements, combined with energy efficiency, make them a cost-effective solution for cooling towers.

Applications in Cooling Towers

FRP louvers are utilized in various types of cooling towers, including natural draft and mechanical draft towers. In mechanical draft cooling towers, these louvers effectively control the airflow, maximizing heat transfer while minimizing water loss through evaporation. In natural draft towers, they can aid in enhancing the natural airflow, effectively supporting the cooling process without supplemental energy consumption.

Furthermore, FRP louvers can be strategically placed to direct airflow towards critical areas of the tower, improving overall efficiency. Their ability to prevent airborne debris and contaminants from entering the cooling system also helps maintain optimal operation, protecting internal components from damage and fouling.

Conclusion

In conclusion, FRP louvers represent a significant advancement in cooling tower technology. Their corrosion resistance, lightweight, strength, UV stability, and customizability make them a superior choice for enhancing the efficiency and durability of cooling towers. As industries continue to prioritize energy efficiency and sustainability, the adoption of innovative materials like FRP will be key to achieving these goals. In addition, the long-term cost savings associated with reduced maintenance and replacement costs make FRP louvers not just an effective solution but also an economically viable one. Moving forward, the integration of FRP louvers into cooling tower designs will likely become standard practice, driving improvements in both performance and reliability.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025