loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Reinforcing Concrete Structures with Fiber Reinforced Polymer Bars for Enhanced Durability and Strength

The Rise of Fiber Reinforced Polymer Bars in Construction

In recent years, the construction industry has increasingly adopted innovative materials to improve durability, performance, and sustainability. One such material that has gained significant attention is Fiber Reinforced Polymer (FRP) bars. These composite materials, made by combining fibers—such as glass, carbon, or aramid—with a polymer matrix, offer several advantages over traditional construction materials, particularly steel reinforcement bars (rebar).

What are FRP Bars?

Fiber Reinforced Polymer bars are composite materials that consist of a polymer matrix reinforced with fibers. The fibers increase the mechanical properties of the polymer, making it stronger and more resilient. The most common types of fibers used in FRP bars include glass fibers (GFRP), carbon fibers (CFRP), and aramid fibers (AFRP). These bars are used primarily in concrete structures as a replacement for steel reinforcing bars, offering unique benefits that enhance performance in various applications.

Advantages of FRP Bars

1. Corrosion Resistance One of the most significant benefits of FRP bars is their resistance to corrosion. Steel rebar is prone to rust and deterioration when exposed to moisture and chemicals, particularly in environments with de-icing salts or seawater. In contrast, FRP bars do not corrode, leading to longer service life and reduced maintenance costs.

2. Lightweight FRP bars are much lighter than steel bars, which simplifies handling and installation processes. A lighter material can reduce transportation costs and labor requirements, making construction projects more efficient.

3. High Strength-to-Weight Ratio Despite being lightweight, FRP bars possess a high strength-to-weight ratio. This means they can provide adequate reinforcement while minimizing the overall weight of the structure. This property is particularly beneficial in constructing buildings, bridges, and other infrastructure where weight is a critical factor.

4. Non-Magnetic and Non-Conductive FRP materials are non-magnetic and non-conductive, making them suitable for applications in environments where these properties are essential, such as in electrical and magnetic field applications or sensitive electronic environments.

fiber reinforced polymer bars

5. Design Flexibility The production of FRP bars allows for various shapes and sizes, providing architects and engineers with greater design flexibility. They can be tailored to meet specific project requirements, allowing for innovative design solutions that traditional materials may constrain.

6. Sustainability As the construction industry moves towards more sustainable practices, FRP bars offer an environmentally friendly alternative to conventional materials. Their longevity reduces the need for frequent replacements, and their production can be designed to minimize environmental impact.

Applications of FRP Bars

FRP bars are increasingly being used in a variety of applications, including bridges, highways, parking garages, and coastal structures. Their resistance to corrosion makes them particularly useful in harsh environments, such as marine applications and structures exposed to road salts. Additionally, FRP bars are used in the retrofitting of existing structures to enhance their durability and performance without significantly increasing weight.

Challenges and Future Prospects

Despite their numerous advantages, the adoption of FRP bars in construction is not without challenges. The higher initial cost compared to steel rebar can be a barrier for many projects. However, when considering the long-term benefits, including reduced maintenance and longer service life, the total cost of ownership may favor FRP materials.

As technology continues to advance, the manufacturing processes for FRP bars are expected to improve, potentially lowering costs and increasing accessibility. Research and development efforts are also focused on enhancing the properties of FRP materials, such as strength and thermal stability, which could broaden their application scope even further.

Conclusion

As the demand for durable, efficient, and sustainable construction materials continues to grow, Fiber Reinforced Polymer bars are positioned to play a pivotal role in the future of construction. Their unique properties, including corrosion resistance, lightweight nature, and design flexibility, make them an attractive alternative to traditional steel reinforcement. As industries evolve and adopt innovative practices, FRP bars embody the potential for safer, more resilient infrastructure that meets the challenges of tomorrow.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

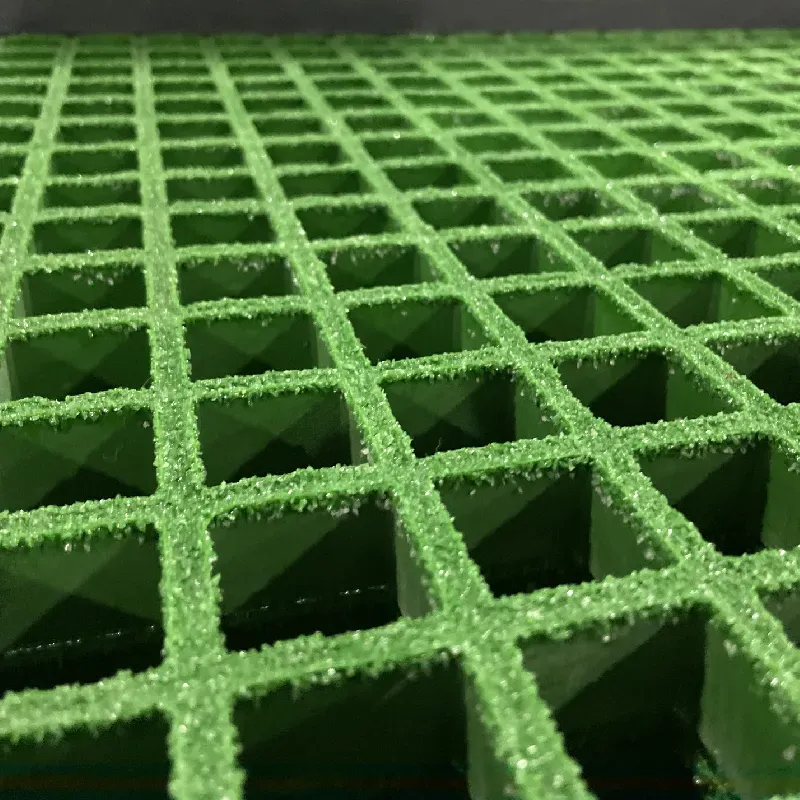

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025