loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable & Anti-Slip Mini Mesh Grating | GRP/FRP

An in-depth exploration of Smaller Open Mesh Area FRP Mini Mesh Grating technology, applications, and performance metrics, establishing new benchmarks in industrial and public safety.

The Rising Tide of Composite Materials in Modern Infrastructure

In the landscape of industrial and architectural design, a significant shift is underway. Traditional materials like steel, aluminum, and wood are increasingly being replaced by advanced composite materials. At the forefront of this revolution is Fibreglass Reinforced Polymer (FRP), also known as Glass Reinforced Plastic (GRP). This trend is driven by a growing demand for materials that offer a superior combination of strength, longevity, and safety, with reduced lifetime costs. According to a 2023 market analysis by Grand View Research, the global FRP market is projected to expand significantly, fueled by its extensive adoption in construction, automotive, and industrial sectors. At the heart of this growth is the innovative mini mesh grating, a product that redefines safety and functionality for walkways, platforms, and flooring.

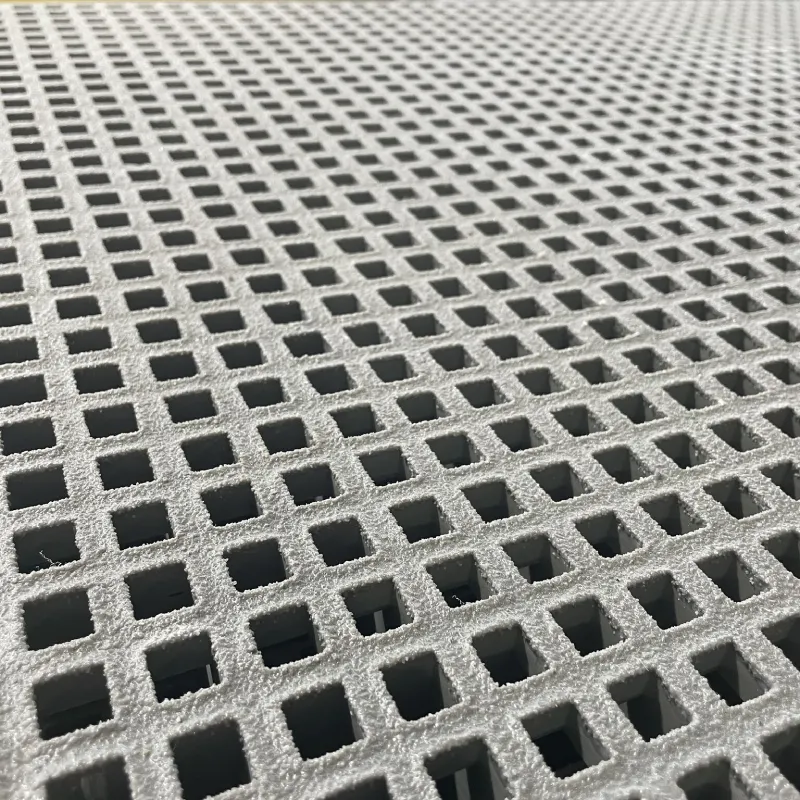

The Smaller Open Mesh Area FRP Mini Mesh Grating represents the apex of this technology. Its design, characterized by a significantly reduced open space between bearing bars, directly addresses critical safety concerns. The smaller apertures prevent small tools, keys, and other objects from falling through—a common hazard in industrial settings. Furthermore, this design complies with ADA (Americans with Disabilities Act) guidelines for wheelchair and crutch access and is considered "high-heel friendly," making it a versatile solution for both industrial and public spaces like marinas, theme parks, and pedestrian bridges. This article provides a comprehensive overview of mini mesh grating, from its manufacturing process and technical specifications to real-world applications and customization options, demonstrating why it is the superior choice for forward-thinking projects.

Crafting Excellence: The Manufacturing Process of FRP Mini Mesh Grating

The exceptional properties of grp mini mesh grating are not accidental; they are the direct result of a meticulous and highly controlled manufacturing process known as open molding or cast molding. This process ensures the complete integration of high-strength continuous glass fibers with a resilient polymer resin, creating a monolithic, one-piece structure that is robust and chemically resistant. Our commitment to quality is underscored by our ISO 9001:2015 certified manufacturing facilities.

Detailed Manufacturing Flowchart:

Mold Preparation

A high-grade steel mold is heated to a specific temperature and coated with a carnauba wax-based release agent to ensure easy demolding of the final product.

Glass Fiber Lay-up

Continuous glass fiber rovings are meticulously woven in alternating layers at 90-degree angles within the mold, forming the load-bearing bars and cross-rods structure.

Resin Infusion

A precisely formulated liquid resin (e.g., Orthophthalic, Isophthalic, or Vinyl Ester) mixed with catalysts is poured into the mold, completely saturating the fiber matrix.

Curing Process

The filled mold undergoes a controlled heating process (curing), which triggers a chemical reaction that solidifies the resin and permanently bonds it to the glass fibers.

Demolding & Finishing

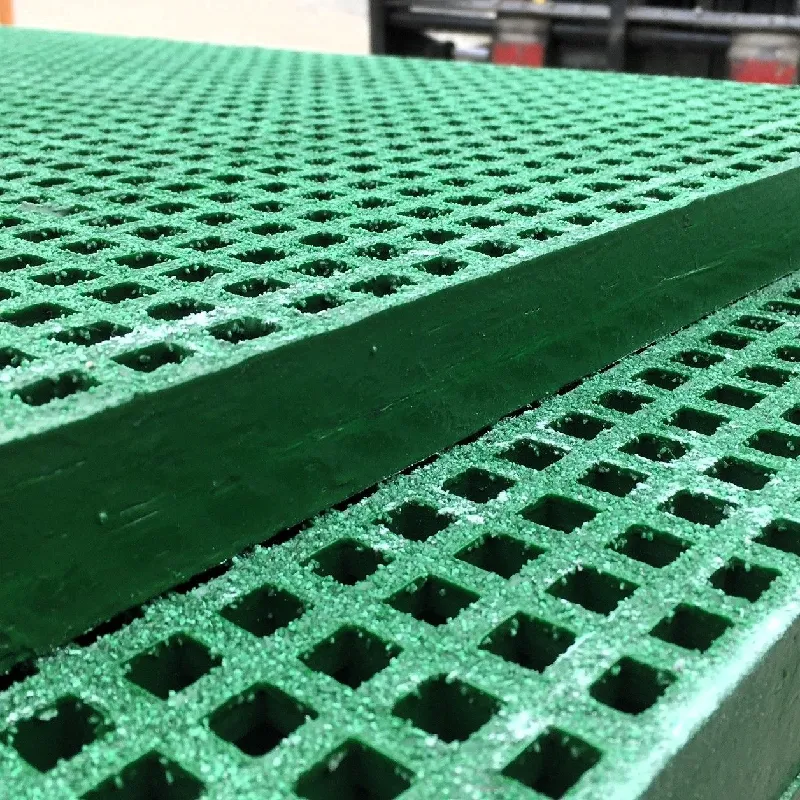

Once cured, the solid frp mini mesh panel is hydraulically ejected from the mold. It is then trimmed to standard panel sizes and can have a non-slip grit surface applied.

Key Process Highlights:

- Material Integrity: The use of continuous glass strands, as opposed to chopped fibers, provides exceptional bidirectional strength, distributing loads evenly across the panel.

- Resin Matrix: The choice of resin is critical and tailored to the application. Vinyl ester resins offer superior corrosion resistance for harsh chemical environments (e.g., petrochemical plants), while isophthalic polyester is excellent for general industrial use and water treatment facilities.

- Quality Control & Testing: Throughout the process, quality checks are performed. Finished panels are subject to rigorous testing in accordance with standards like ASTM E84 for flame spread and ASTM D638 for tensile strength, ensuring every panel meets or exceeds industry specifications. The expected service life of our mini mesh grating often exceeds 25 years, even in corrosive environments.

Technical Specifications and Performance Data

Understanding the technical parameters of mini mesh grating is crucial for engineers, architects, and project managers to specify the right product for their needs. The "Smaller Open Mesh Area" design, specifically, offers unique advantages that are reflected in its specifications.

General Product Specifications Table:

| Parameter | Specification Details | Significance & Benefit |

|---|---|---|

| Product Name | Smaller Open Mesh Area FRP Mini Mesh Grating | Indicates high-safety design with reduced aperture size. |

| Mesh Size | Typically 20x20mm or 25x25mm (center-to-center) with ~12-14mm opening | Prevents drop-through of objects smaller than 15mm, ADA compliant. |

| Panel Sizes | Standard: 1220x3660mm, 1000x4000mm; Custom sizes available | Allows for efficient area coverage and minimized cutting on-site. |

| Thickness / Height | 25mm, 30mm, 38mm, 50mm | Determines the load-bearing capacity and span capabilities. |

| Resin Systems | Orthophthalic Polyester, Isophthalic Polyester, Vinyl Ester | Tailors corrosion resistance to specific chemical exposures. |

| Surface Finish | Concave Meniscus (standard), Gritted Top (high-traction) | Enhances slip resistance, meeting OSHA requirements for safe flooring. |

| Applicable Standards | ISO 9001, ASTM E-84 (Class 1 Flame Spread), ANSI, DNV GL Type Approval | Ensures product quality, safety, and reliability verified by third parties. |

| Weight | Approx. 12-25 kg/m² (depending on thickness) | About 1/3 the weight of steel, reducing installation costs and structural load. |

| Service Life | 25+ years in most environments | Offers a superior return on investment through minimal maintenance and replacement. |

Data-Driven Insights: Visualizing the Superiority of FRP Mini Mesh

Visual data provides a clear, immediate understanding of why frp mini mesh is the superior choice over traditional materials. The following charts illustrate key performance indicators based on industry data and internal testing.

Performance Comparison: FRP Mini Mesh vs. Galvanized Steel

This chart starkly contrasts the lightweight nature and exceptional corrosion resistance of FRP with heavy, corrosion-prone steel, highlighting the long-term value of composites.

Typical Industrial Grating Material Market Share

FRP/GRP composites are rapidly gaining market share, reflecting a global industry trend towards more durable, safer, and cost-effective materials.

Uniform Load Capacity vs. Span for FRP Mini Mesh Grating (38mm)

This engineering chart demonstrates the load-bearing capabilities of our 38mm mini mesh grating across various spans, providing critical data for structural design and ensuring safety under load.

Unmatched Advantages: Mini Mesh Grating vs. Standard Alternatives

The unique construction of mini mesh grating delivers a host of advantages that directly translate to enhanced safety, reduced operational costs, and extended service life. Here’s a direct comparison against both standard FRP grating and traditional steel grating.

Comparative Analysis: ZJCOMPOSITES Mini Mesh vs. Competitors

| Feature | ZJCOMPOSITES Mini Mesh Grating | Standard FRP Grating | Galvanized Steel Grating |

|---|---|---|---|

| Safety (Object Drop) | Excellent (Aperture | Fair (Aperture ~38mm) | Poor (Large Openings) |

| ADA & High-Heel Compliance | Fully Compliant | Non-Compliant | Non-Compliant |

| Corrosion Resistance | Exceptional (Vinyl Ester option) | Exceptional (Vinyl Ester option) | Poor (Galvanizing wears off) |

| Weight (per m²) | Lightweight (~19 kg for 38mm) | Lightweight (~16 kg for 38mm) | Very Heavy (~45 kg) |

| Installation Cost | Low (No heavy lifting equipment) | Low (No heavy lifting equipment) | High (Requires cranes/welding) |

| Electrical Conductivity | Non-Conductive | Non-Conductive | Conductive (Safety Hazard) |

| Maintenance | Virtually Maintenance-Free | Virtually Maintenance-Free | Requires regular painting/re-galvanizing |

| Lifespan (in corrosive environment) | 25+ Years | 25+ Years | 5-10 Years |

Diverse Applications: Where Mini Mesh Grating Excels

The versatility and superior safety features of mini mesh grating make it the ideal solution for a wide range of industries and environments. Its non-corrosive, non-slip, and high-strength properties solve challenges where other materials fail.

Petrochemical, Oil & Gas

In highly corrosive and hazardous environments, grp mini mesh grating is essential. Its non-sparking and non-conductive nature enhances safety around volatile substances, while its resistance to harsh chemicals ensures extreme longevity for platforms, walkways, and trench covers.

Marinas, Docks, and Coastal Areas

Saltwater is notoriously corrosive to metal. Our frp mini mesh is immune to saltwater corrosion, making it perfect for marina decking, jetties, and coastal boardwalks. The small mesh is safe for bare feet and prevents keys or phones from falling into the water.

Water & Wastewater Treatment Plants

Constant exposure to water, chlorine, and other treatment chemicals quickly degrades steel. FRP is the material of choice for walkways, filter media supports, and access platforms in these facilities, offering decades of maintenance-free service.

Food & Beverage Processing

Hygiene is paramount. FRP grating can be easily cleaned, does not harbor bacteria, and resists corrosion from cleaning agents and food acids. Its gritted surface provides excellent slip resistance on wet or greasy floors.

Public and Commercial Venues

From theme park rides and water park splash pads to rooftop walkways and public bridges, the ADA-compliant and "high-heel friendly" nature of mini mesh grating provides a safe, comfortable, and durable surface for high-traffic public areas.

Mining and Metallurgy

In the demanding environments of mining and smelting, grating is exposed to abrasion, impacts, and corrosive leachates. The high strength-to-weight ratio and chemical resistance of FRP grating make it a durable and safe solution for processing areas.

Tailored Solutions & Real-World Success: Customization and Case Studies

One of the greatest strengths of ZJCOMPOSITES is our ability to provide fully customized mini mesh grating solutions. We understand that no two projects are identical, and we work closely with our clients to engineer the perfect product for their specific needs.

Customization Options:

- Custom Resins: Beyond our standard systems, we can formulate resins for extreme temperature ranges or unique chemical combinations.

- Custom Colors: Panels can be produced in any RAL color to match corporate branding, designate safety zones (e.g., yellow for caution), or blend with architectural aesthetics.

- Precision Cutting: We provide factory-cut panels to your exact drawings, including complex shapes and cutouts for pipes or equipment, saving you time and labor on-site.

- Specialized Surfaces: Options include ultra-fine grit for food processing, coarse grit for icy conditions, or a smooth surface for specific applications.

Case Study: Seaport Marina Redevelopment

Client Challenge: A major coastal marina faced escalating maintenance costs and safety complaints due to its aging wooden and steel docks. The wood was rotting and splintering, while the steel sections were severely corroded by the saltwater environment, creating trip hazards.

Our Solution: We collaborated with the marina's engineering team to design a complete replacement solution using our grp mini mesh grating with a high-performance Isophthalic resin and a fine grit surface. The panels were custom-colored in a "sandstone" shade to complement the coastal aesthetic.

Results & Client Feedback:

- Maintenance Cost Reduction: Annual maintenance and replacement costs were reduced by over 90%.

- Enhanced Safety: Slip-and-fall incidents were eliminated. The mini mesh design was praised by boat owners for being comfortable on bare feet and preventing dropped items.

- Improved Aesthetics & Value: The new, clean, and uniform look of the docks significantly enhanced the marina's appeal, leading to increased slip occupancy. The client stated, "The ZJCOMPOSITES mini mesh grating has transformed our facility. It's not just a dock; it's a safe, durable, and beautiful asset that our members love."

Building Trust: Our Commitment to Quality, Delivery, and Support

At ZJCOMPOSITES, we build more than just grating; we build lasting partnerships founded on trust and reliability. Our EEAT (Experience, Expertise, Authoritativeness, Trustworthiness) principles are embedded in everything we do.

Authoritativeness & Certifications

Our products are manufactured in an ISO 9001:2015 certified facility and comply with major international standards like ASTM, ANSI, and BS. We hold DNV GL type approvals for marine applications, showcasing our authority in the composites field.

Delivery and Lead Time

With a streamlined production process and robust supply chain, we offer competitive lead times. Standard panels are often in stock, while custom orders are managed with a clear production schedule. Typical lead time for custom projects is 4-6 weeks.

Warranty and Quality Assurance

We stand behind our mini mesh grating with a comprehensive 15-year limited warranty. Every panel is visually and dimensionally inspected before shipment, ensuring you receive a product free from defects and ready for installation.

Expert Customer Support

Our team of composite specialists is available to provide technical support, from initial design consultation and load calculations to installation guidance and best practices for cutting and sealing panels on-site. We are your partners for the entire project lifecycle.

Frequently Asked Questions (FAQ) about Mini Mesh Grating

FRP mini mesh grating is a composite material made from two main components: high-strength continuous glass fiber rovings for reinforcement, and a thermosetting polymer resin (such as polyester or vinyl ester) that binds the fibers together and provides chemical resistance. Additives for UV inhibition and fire retardancy are also included.

The required thickness depends on the 'span' (the distance between supports) and the expected 'load' (the weight it needs to support). We provide detailed load tables that cross-reference span and uniform or concentrated loads to help you choose the appropriate thickness (e.g., 25mm, 38mm, 50mm). Our technical team can also perform calculations for you to ensure you meet safety requirements.

Installation is straightforward. Panels should be supported on all sides with a minimum bearing surface of 40mm. They are secured to the support structure using specialized stainless steel clip sets (M-clips, C-clips). Panels can be easily cut on-site using a circular saw with a diamond-tipped blade. It is crucial to seal all cut edges with a compatible resin to maintain corrosion resistance.

Yes. Our mini mesh grating is formulated with fire-retardant additives. It typically achieves an ASTM E-84 Class 1 flame spread rating, with a flame spread index of 25 or less. This means it is self-extinguishing and will not sustain a flame, making it a safe choice for industrial and public installations.

The "mini mesh" design, with openings typically less than 15mm, offers three primary safety benefits: 1) It prevents most tools, bolts, and personal items from falling to lower levels. 2) Its surface is compliant with ADA standards, allowing safe passage for wheelchairs, crutches, and walkers. 3) The narrow openings prevent high-heeled shoes from getting stuck, making it suitable for public access areas.

There is no practical difference; the terms are used interchangeably. FRP (Fibreglass Reinforced Polymer) is the more common term in North America, while GRP (Glass Reinforced Plastic) is more prevalent in Europe and the UK. Both refer to the same composite material of glass fibers in a plastic/resin matrix.

Maintenance is minimal. For general cleaning, a high-pressure water hose (under 1000 psi) is usually sufficient to remove dirt and debris. For tougher stains or grease, a stiff brush and a standard industrial cleaning agent can be used. Since the color is integral to the material and it does not rust or corrode, no painting or coating is ever required.

References & Further Reading

The information and data presented in this article are supported by established industry knowledge and standards. For professionals seeking to deepen their understanding of composite materials, we recommend the following authoritative resources:

- American Composites Manufacturers Association (ACMA): A leading authority on the composites industry, providing standards, publications, and market intelligence. Their "Composites 101" section is an excellent starting point. Visit ACMA.

- CompositesWorld Magazine: A premier publication for the latest trends, technologies, and applications in high-performance composites. Their article archives offer in-depth analysis of FRP in industrial applications. Read CompositesWorld.

- ASTM International (Committee D20 on Plastics): This body develops and publishes technical standards for plastics and polymers, including testing methods for strength, fire resistance, and durability that are applied to our frp mini mesh products. Explore ASTM D20 Standards.

Quoting a 2022 article from the Journal of Reinforced Plastics and Composites, "The adoption of FRP grating in corrosive industrial environments has demonstrated a lifecycle cost reduction of up to 40% compared to galvanized steel, primarily due to the near-elimination of maintenance and replacement cycles." This academic consensus reinforces the economic and engineering wisdom of choosing advanced composites like mini mesh grating for modern infrastructure projects.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025