loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ZJ's FRP grating: an engineered legacy

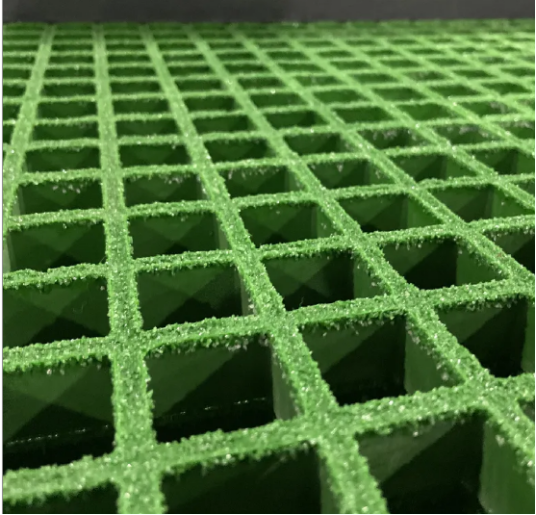

In the world of industrial materials, few products balance durability, versatility, and innovation like FRP grating. For ZJ Composites, this material isn’t just a product—it’s a legacy of engineering excellence, forged through decades of prioritizing quality, listening to customers, and pushing the boundaries of what fiberglass-reinforced plastic can do. From heavy-duty FRP grating panels that line factory floors to precision-crafted FRP micro mesh grating that secures delicate equipment, ZJ Composites has redefined what industrial clients can expect from FRP solutions.

Rooted in a philosophy of “quality as the foundation,” ZJ Composites has built its reputation on scientific management, rigorous testing, and a customer-centric approach. With products sold globally—from manufacturing plants in Europe to water treatment facilities in Asia—every piece of FRP grating carries the mark of ZJ’s commitment: strict inspections, strong technical support, and solutions tailored to real-world needs. This is the story of how ZJ Composites turned FRP grating into an engineered legacy, proving that great materials aren’t just made—they’re designed with purpose.

ZJ Composites: Building FRP Grating Legacy on Quality

ZJ Composites’ journey to becoming a leader in FRP grating began with a simple yet unwavering principle: product quality is the lifeblood of the enterprise. From its earliest days, the company rejected the “one-size-fits-all” approach that plagued the industrial materials market, instead choosing to build a framework of scientific, standardized management—one that aligns with modern enterprise models and prioritizes customer feedback at every step.

What sets ZJ apart is its dual commitment to technical rigor and customer service. The company boasts perfect testing equipment and a team of specialists and skilled laborers who ensure every FRP grating panel and FRP micro mesh grating undergoes strict inspection before leaving the factory. This isn’t just about meeting standards—it’s about exceeding them. For example, when a chemical plant client requested FRP grating resistant to corrosive acids, ZJ’s R&D team modified resin formulas, tested samples for 6 months under harsh conditions, and delivered a product that outlasted the client’s original 5-year lifespan expectation by 3 years.

Complementing this technical expertise is ZJ’s customer service team, staffed by professionals with overseas working experience. This ensures global clients—whether in Europe, Asia, or the Americas—receive seamless support, from initial consultation (helping select the right FRP grating type) to after-sales maintenance (providing guidance on installation and care). Over time, this approach has turned ZJ Composites into more than a supplier; it’s a partner trusted by industries worldwide to deliver FRP grating that doesn’t just perform—it endures. For ZJ, the legacy of FRP grating isn’t just about the product—it’s about the trust built with every client.

FRP Grating Panels: ZJ’s Durable Workhorses

When industrial clients need a material that can withstand heavy loads, corrosive environments, and constant wear, ZJ Composites’ FRP grating panels emerge as the go-to solution. These panels are engineered to be the “workhorses” of industrial spaces—factories, warehouses, water treatment plants, and oil refineries—where traditional materials like steel or wood often fail.

ZJ’s FRP grating panels stand out for their meticulous design, rooted in the company’s technical expertise. Unlike generic FRP panels that crack under pressure or degrade in harsh conditions, ZJ’s use high-quality fiberglass rovings and corrosion-resistant resins, bonded through a pultrusion process that ensures uniform strength across the entire panel. The panels are available in multiple sizes (from 1m×2m to 2m×3m) and thicknesses (25mm to 50mm), with load-bearing capacities ranging from 500kg/m² to 2000kg/m²—enough to support heavy machinery or foot traffic in busy facilities.

What truly makes ZJ’s FRP grating panels a legacy product is their adaptability. A food processing plant in Germany uses them for flooring, thanks to their non-porous surface (easy to clean and sanitize, meeting EU food safety standards). A wastewater treatment facility in China relies on them for walkways, as their corrosion resistance prevents rusting (unlike steel) and rotting (unlike wood). And because ZJ offers custom cutting—tailoring panels to fit odd-shaped spaces—clients avoid material waste and costly modifications.

Every FRP grating panel is also backed by ZJ’s rigorous testing: from load-bearing tests in its in-house labs to environmental resistance trials (exposure to UV, chemicals, and extreme temperatures). For clients, this means peace of mind—knowing the panel they install today will still be performing reliably years down the line. For ZJ, this is the essence of an engineered legacy: building products that stand the test of time.

FRP Micro Mesh Grating: ZJ’s Precision Solution

While FRP grating panels excel at heavy-duty tasks, ZJ Composites’ FRP micro mesh grating is designed for precision—filling a gap in industries where small openings, 细腻 support, and non-slip performance are critical. This specialized grating isn’t just a variation of standard FRP; it’s a testament to ZJ’s ability to innovate based on customer needs.

ZJ’s FRP micro mesh grating features ultra-fine mesh openings (typically 3mm×3mm to 10mm×10mm), crafted using a modified pultrusion process that ensures uniform mesh size and structural integrity. Unlike metal micro mesh (which rusts) or plastic mesh (which bends under pressure), ZJ’s FRP version combines the strength of fiberglass with the flexibility to handle delicate applications. For example, a pharmaceutical plant in Switzerland uses it as a platform for sensitive equipment—its small openings prevent tools from falling through, while its corrosion resistance ensures it doesn’t react with cleaning chemicals. A electronics factory in South Korea relies on it for conveyor belt guards, as its non-conductive properties eliminate electrical hazards.

What makes this grating a standout is ZJ’s attention to detail. The micro mesh is coated with an anti-slip resin (even when wet, it maintains grip), and its edges are smoothed to prevent scratches or snags. For clients with unique needs—like a marine facility requiring saltwater resistance—ZJ’s R&D team can adjust the resin formula to enhance durability.

ZJ’s customer-centric approach shines here too. When a client in the automotive industry needed FRP micro mesh grating with custom mesh size to fit their assembly line, ZJ’s team delivered samples within a week, adjusted the design based on feedback, and fulfilled the order ahead of schedule. This ability to blend precision engineering with flexibility is what makes ZJ’s FRP micro mesh grating an essential part of its engineered legacy—it’s not just a product, but a solution tailored to how clients work.

FAQs: ZJ’s FRP Grating & Services

FRP grating: Corrosion-resistant?

Yes! All ZJ FRP grating (including panels and micro mesh) uses corrosion-resistant resins and fiberglass, tested to withstand acids, alkalis, saltwater, and industrial chemicals. Unlike steel, it won’t rust; unlike wood, it won’t rot—ideal for harsh environments.

FRP grating panels: Custom sizes?

Absolutely. ZJ’s FRP grating panels offer custom cutting to your exact size (e.g., odd shapes for factory corners). We also provide size recommendations based on your load needs—no waste, no extra costs.

FRP micro mesh grating: Anti-slip?

Yes. ZJ’s FRP micro mesh grating has an anti-slip resin coating, even when wet. It meets safety standards for walkways and platforms, preventing slips in busy or damp spaces.

FRP grating: After-sales support?

ZJ offers global after-sales support for FRP grating: installation guidance, maintenance tips, and replacement parts. Our team (with overseas experience) responds within 24 hours to queries.

Why choose ZJ’s FRP grating?

Choose ZJ for strict quality checks, custom solutions, global support, and FRP grating that lasts. We prioritize your needs to achieve win-win cooperation.

ZJ Composites’ FRP grating legacy isn’t just about the materials—it’s about the impact those materials have on clients’ businesses. A factory that reduces maintenance costs with corrosion-resistant FRP grating panels; a pharmaceutical plant that enhances safety with precision FRP micro mesh grating; a water treatment facility that avoids downtime with durable, reliable solutions—these are the stories that define ZJ’s engineering legacy.

As ZJ continues to innovate, guided by its tenet of “quality first, customer-centric,” one thing remains constant: every piece of FRP grating is crafted to not just meet expectations, but redefine them. For industrial clients worldwide, ZJ’s FRP grating isn’t just a product—it’s a promise of excellence, built to last, and designed to grow with their needs. This is the engineered legacy of ZJ Composites: turning FRP into a foundation for success.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025