loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Finding and Selecting Vessel Manufacturers for Your Needs

Certainly! Here’s an article focused on the theme of filtering vessel manufacturers, which highlights their significance in various industries.

---

The Importance of Filtering Vessel Manufacturers in Modern Industries

In today’s industrial landscape, the demand for efficient and effective filtration systems continues to grow across various sectors, including chemical processing, pharmaceuticals, food and beverage, and water treatment. At the heart of these filtration systems are filtering vessels, designed to separate solids from liquids or gases. The manufacturers of these vessels play a crucial role in ensuring that industries can meet the stringent standards of purity and efficiency required in this modern age.

Understanding Filtering Vessels

Filtering vessels are containers used to hold a filter medium and facilitate the separation process. These vessels come in various sizes and configurations, tailored to meet the specific needs of different applications. They can be simple basket filters, multi-layer filters, or more complex configurations that integrate advanced technologies. The design and material of a filtering vessel greatly influence its performance, durability, and suitability for particular applications.

Key Aspects of Filtering Vessel Manufacturers

1. Innovation and Technology Top manufacturers are constantly innovating. They invest in research and development to introduce new filtering media, designs, and technologies that outperform existing solutions. This innovation often leads to improved efficiency, reduced operational costs, and enhanced sustainability. For example, advanced membrane technologies allow for finer filtration and better pathogen removal, which is particularly important in water treatment and pharmaceutical applications.

2. Customization Different industries have unique requirements. A one-size-fits-all approach does not suffice when it comes to filtration. Leading manufacturers offer customization options to meet specific operational needs. This may include modifications in size, materials, and configurations. Custom-built vessels ensure that clients receive solutions tailored to their operational parameters, thus improving overall effectiveness.

filter vessel manufacturer

3. Quality Assurance Quality is paramount in manufacturing filtering vessels. Manufacturers adhere to strict quality control processes to ensure their products meet regulatory standards and customer expectations. This includes the use of high-grade materials, rigorous testing, and adherence to international standards such as ASME, FDA, and ISO certifications.

4. Expertise and Support An experienced manufacturer often provides invaluable expertise in filtration processes. They can assist clients in selecting the right vessel for their needs, optimizing systems, and troubleshooting issues. This support is crucial for ensuring that filtration systems operate efficiently and effectively, minimizing downtime and maintenance costs.

5. Sustainability In an era where environmental constraints are becoming increasingly pressing, filtering vessel manufacturers are focusing on sustainability. They develop vessels that are not only energy-efficient but also made from recyclable materials. Additionally, sustainable practices in manufacturing processes help reduce waste and energy consumption.

Industry Applications

The applications of filtering vessels are diverse. In the pharmaceutical industry, they are critical for ensuring the purity of products and compliance with health regulations. In food and beverage production, filtering vessels help in removing contaminants and maintaining product quality while enhancing flavors and shelf life. Water treatment plants rely heavily on filtering vessels to ensure safe drinking water, making effective filtration essential for public health.

Conclusion

Filtering vessel manufacturers are pivotal in facilitating efficient processes across different industries. As technology advances and regulatory requirements become more stringent, the role of these manufacturers becomes even more critical. Their commitment to innovation, quality, customization, and sustainability ensures that businesses can rely on their filtration systems to deliver consistent results. As industries look towards the future, partnering with reputable filtering vessel manufacturers will be essential for achieving operational success and adhering to the highest standards of quality and safety.

---

This article provides an overview of the significance of filtering vessel manufacturers, touching upon their roles, innovations, and industry applications.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

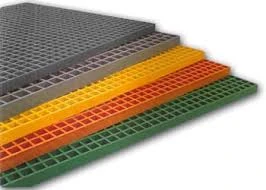

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025