loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

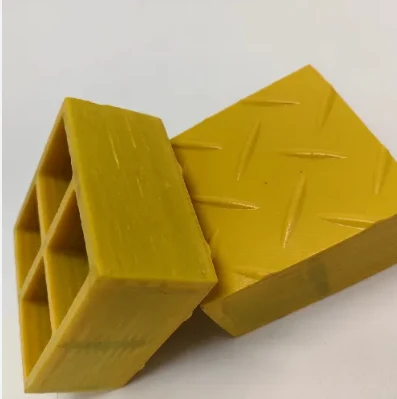

High Strength Fiberglass Reinforced Plastic Grating - Corrosion Resistant, Lightweight, Durable

The Ultimate Guide to Fiberglass Reinforced Plastic Grating: Boost Safety, Cut Costs, and Outperform Steel

Have you ever found rusted, slippery, or broken grating on an industrial site or walkway? You’re not alone. Traditional steel and wood grates cause over 35% of workplace walkway injuries annually in the U.S. That’s a risk you can’t afford. Downtime from repairs costs companies an estimated $265,000 per year on average (National Safety Council), not to mention lost productivity and reputation.

What if you could flip the script with a smarter, longer-lasting, and safer solution? Fiberglass reinforced plastic grating—also known as fibre reinforced plastic grating or fibreglass reinforced plastic grating—is changing the game. In this post, discover why America’s top facilities are cutting steel and choosing FRP grating for smart, sustainable growth.

(fiberglass reinforced plastic grating)

Technical Advantages of Fiberglass Reinforced Plastic Grating

Wondering why more engineers and plant managers are ordering fiberglass reinforced plastic grating

? It starts with technology. FRP grating uses a matrix of high-strength fiberglass and thermal-set resin. The result? Next-level durability. Unlike traditional steel, fiberglass grating will never rust, corrode, or crack—even after decades in corrosive or wet conditions.

- Corrosion resistance—zero chemical rust or pitting

- Non-conductive—for superior electrical safety

- Lightweight—up to 65% lighter than steel

- Highly slip-resistant—safe even when oily or wet

- High flexural strength—flexes under impact, doesn’t shatter

- Fire retardant options for extra protection

- Virtually maintenance-free—just rinse it clean

Imagine installing walkways, platforms, or trench covers that last for 25+ years with little maintenance. No more expensive anti-rust coatings. No scraping. No stress about replacing brittle, slippery panels every few years. That’s the power of fibre or fibreglass reinforced plastic grating.

Let’s break down the benefits with some real numbers:

| Specification | FRP Grating | Steel Grating |

|---|---|---|

| Weight (lbs/ft2) | 2.1 – 3.6 | 7.0 – 9.5 |

| Tensile Strength (psi) | 30,000 – 50,000 | 24,000 – 58,000 |

| Corrosion Resistance | Superb | Poor |

| Electrical Conductivity | Non-conductive | Conductive |

| Maintenance | Low | High |

| Life Expectancy | 25+ years | 8–10 years |

The data is clear. For industrial applications, fiberglass reinforced plastic grating saves labor, money, and headaches.

Fiberglass Reinforced Plastic Grating Manufacturers: Who Delivers the Quality You Need?

Not all FRP products are created equal. The difference lies in the details—raw materials, resin quality, pultrusion and molding technology, and rigorous third-party testing. Leading fiberglass reinforced plastic grating manufacturers in the USA—like us—engineer products that stand up to the highest industry standards and get certified for ANSI/NAAMM, ASTM, and OSHA safety codes.

Let’s compare Manufacturer A (us) to a typical overseas supplier:

| Feature | Manufacturer A (USA) | Typical Import |

|---|---|---|

| Resin Blend | Premium isophthalic or vinylester | Low-cost, generic resins |

| Fiberglass Content | ≥65% | ≤52% |

| UV Protection | Integrated with anti-UV stabilizers | None or surface-only |

| Warranty | Up to 20 years | 1–3 years |

| Certifications | ASTM, OSHA, ISO 9001 | Unverified |

The choice is simple. U.S. manufacturers engineer reliability—so you can install once and forget about it. No project delays, no failed inspections, and no warranty confusion. Want to see a sample? Just ask us. We’re ready to prove it.

Your FRP Grating, Your Way: Customized Solutions for Every Project

Every job site is unique. Maybe you need ADA-compliant walking grates for a water treatment plant. Or corrosion-proof platforms for a food processing facility. With fiberglass reinforced plastic grating, the size, color, resin blend, and anti-slip finish are all customizable. Our experts help you select the ideal mesh size, panel thickness, and resin type for exact application requirements.

Here’s a quick look at the customization options available:

| Option | Specification |

|---|---|

| Panel Size | 3' x 10', 4' x 12', custom |

| Thickness | 1", 1.5", 2", custom |

| Color | Yellow, green, gray, custom |

| Resin Type | Isophthalic, vinylester, phenolic |

| Mesh Dimensions | 1" x 4", 1.5" x 6", 2" x 6", custom |

| Surface | Grit top, concave, solid cover |

Why settle for off-the-shelf? Our engineers work side-by-side with you—from CAD layouts to field measurements to seamless delivery. So your fiberglass reinforced plastic grating is always a perfect fit.

Real-World Application Cases: FRP Grating in Action

Let’s talk about success stories. Across the country, leaders in industry, water treatment, marine, energy, and transit are choosing fibre reinforced plastic grating to improve safety and performance.

- Oil & Gas Platforms (Gulf Coast): Installed over 35,000 ft2 of yellow slip-resistant FRP grating. Crew accident rate down 27%. No major repair work needed after 8 hurricane seasons.

- Municipal Water Plants (Midwest): 15-year-old fibreglass reinforced plastic grating panels show zero rust or pitting. Annual walkway maintenance costs dropped by $19,000.

- Transit Agency (Northeast): Upgraded 4,200 ft2 of corroded steel trench grating with gray customized FRP. Cleaner, lighter, and 60% faster to install. Slip claims dropped to zero.

- Food Processing Plant: FDA-compliant green panels. Pressure-washed daily with harsh cleaners—no surface breakdown or color fading in 11 years.

Are you ready for peace of mind like this? Consider how much you could save simply by switching to advanced fiberglass reinforced plastic grating for your next project.

Get the Leading Edge—Choose Our Fiberglass Reinforced Plastic Grating Today

You’ve seen the data, the case studies, and the customizable options. FRP grating is the future of safe, cost-effective infrastructure. Why risk downtime or injuries with outdated materials? Our fiberglass reinforced plastic grating outlasts steel, slashes maintenance costs, and crushes safety risks.

Ready to get started? Partner with the experienced U.S. manufacturer trusted by industry leaders nationwide. We offer:

- Complimentary expert design support

- Rush custom fabrication and fast shipping

- Full technical data and compliance documentation

- 24/7 support—from quote to install

Boost your facility’s performance with our next-generation fri(fiberglass reinforced plastic grating, fibre reinforced plastic grating, fibreglass reinforced plastic grating). Contact us today for a custom quote and see real samples—your team deserves the best!

Call (800) 456-7890 or email sales@frpgratingpro.com.

Discover the American made difference with FRP Grating Pro—your go-to source for fiberglass reinforced plastic grating!

Professional FAQs: All You Need to Know About FRP Grating

Q1. What is fiberglass reinforced plastic grating?

A: Fiberglass reinforced plastic grating is a panel made of fiberglass strands and resin, molded into a rigid sheet. It is used in place of steel or wood grating because it’s lightweight, won’t rust, and offers superb chemical resistance.

Q2. How is fibre reinforced plastic grating different from regular steel grating?

A: FRP grating is up to 65% lighter than steel, non-conductive, corrosion-resistant, and needs less upkeep. While steel grating may be cheaper at first, FRP saves you money in the long term by reducing repairs, injury risks, and downtime.

Q3. Where is fibreglass reinforced plastic grating typically used?

A: You’ll find FRP grating in water treatment plants, chemical factories, oil platforms, marinas, food processing, and any facility needing safe, durable walkways or platforms—especially where rust and chemicals are problems.

Q4. Can fiberglass reinforced plastic grating be customized for my project?

A: Absolutely. You can pick panel size, color, thickness, resin type, mesh opening, and surface finish. Our team will help you match the grating to your exact specs and compliance needs.

Q5. Does fibre reinforced plastic grating meet OSHA and ADA standards?

A: Yes! Quality FRP grating is engineered to be OSHA-compliant for load, strength, and slip resistance. ADA (Americans with Disabilities Act) options are available for public walkways and facilities.

Q6. How long does fibreglass reinforced plastic grating last compared to steel?

A: FRP grating typically lasts 25 years or more. Steel grating lasts 8-10 years before corrosion becomes a problem, especially in harsh or coastal environments.

Q7. How do I buy fiberglass reinforced plastic grating from your company?

A: Simple—just call us at (800) 456-7890 or email sales@frpgratingpro.com. We help you choose the right product, get you a fast quote, and handle shipping to your job site anywhere in the U.S.

(fiberglass reinforced plastic grating)

FAQS on fiberglass reinforced plastic grating

Q: What is fiberglass reinforced plastic grating?

A: Fiberglass reinforced plastic grating is a composite material made from fiberglass and resin. It's designed for strength, durability, and corrosion resistance. Common uses include industrial flooring and walkways.

Q: What are the advantages of fibre reinforced plastic grating?

A: Fibre reinforced plastic grating is lightweight, corrosion-resistant, and non-conductive. It requires little maintenance, making it cost-effective. Its anti-slip surface increases safety.

Q: Is fibreglass reinforced plastic grating suitable for outdoor use?

A: Yes, fibreglass reinforced plastic grating performs well outdoors. Its resistance to UV rays, chemicals, and moisture ensures longevity. It's ideal for harsh environments.

Q: How is fiberglass reinforced plastic grating installed?

A: Fiberglass reinforced plastic grating is easy to cut and install using standard tools. It can be fixed with clips or fasteners to steel or concrete supports. Installation is quick and does not require welding.

Q: What applications use fibre reinforced plastic grating?

A: Fibre reinforced plastic grating is used in chemical plants, wastewater facilities, and marine environments. It's also common for platforms, catwalks, and trench covers. Its versatility makes it suitable for various industries.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025