laster inn...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, Kina

- admin@zjcomposites.com

- +86 15097380338

- Velkommen til å besøke nettsiden vår!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Engelsk

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

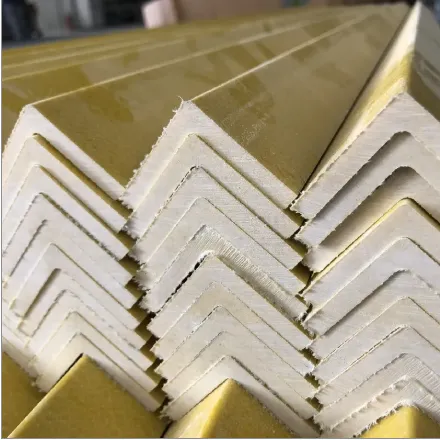

The Rise of FRP Profiles

In today’s manufacturing and construction industries, FRP profiles are becoming an essential material for a wide range of applications. These profiles, made from Fiber Reinforced Plastic (FRP), are known for their strength, durability, and versatility. With the introduction of FRP pultruded profiles and FRP pultruded sections, businesses can now take advantage of high-performance, lightweight materials to create better and more cost-effective structures. In this article, we’ll explore how these profiles are revolutionizing industries and why they’re an excellent choice for a variety of purposes.

What are FRP Profiles?

FRP profiles are composite materials that combine the flexibility of plastic with the strength of fibers. These profiles are made by embedding fibers like fiberglass into a resin matrix, providing superior strength-to-weight ratios and corrosion resistance. FRP profiles are widely used in sectors such as construction, transportation, and infrastructure due to their ability to withstand harsh environments and their lightweight nature.

The primary advantage of FRP profiles is their ability to resist corrosion from chemicals, water, and extreme weather conditions, which is a common issue with traditional materials like steel or aluminum. This makes FRP profiles ideal for applications in industries such as oil and gas, marine, and even wastewater treatment. The lightweight nature of these profiles also allows for easy handling and installation, making them an efficient choice for various construction projects.

The strength of FRP profiles makes them suitable for structural applications, such as framing, flooring, and panels, while their flexibility allows them to be molded into different shapes and sizes. As demand grows for environmentally friendly materials, FRP profiles are becoming a preferred alternative to metal-based profiles, contributing to the sustainable future of manufacturing.

Understanding FRP Pultruded Profiles

FRP pultruded profiles are produced through the pultrusion process, a method that involves pulling continuous fibers through a resin bath and then curing them under heat to form rigid profiles. The term "pultrusion" is derived from the words "pull" and "extrusion," signifying the continuous pulling of fibers through the resin and shaping them into profiles with specific dimensions and properties.

The process of creating FRP pultruded profiles results in a high-performance material that is strong, durable, and resistant to wear and tear. These profiles are ideal for use in a variety of applications, such as bridges, walkways, and electrical enclosures, where strength and resistance to the elements are crucial. The pultrusion process ensures that each FRP pultruded profile has consistent dimensions and high-quality finish, making it a reliable choice for both commercial and industrial projects.

One of the major benefits of FRP pultruded profiles is their versatility. They can be molded into an array of different shapes and sizes to suit specific project needs. This customizability, combined with their durability and lightweight nature, makes FRP pultruded profiles a popular material choice across various sectors, including construction, transportation, and power transmission.

Exploring FRP Pultruded Sections

Similar to FRP pultruded profiles, FRP pultruded sections are manufactured through the pultrusion process, but they typically refer to larger or more complex shapes such as I-beams, channels, and structural angles. These sections are used to create stronger, more robust structures capable of withstanding heavier loads. FRP pultruded sections are used in applications requiring high strength-to-weight ratios and are designed to perform well even in extreme environments.

The main advantage of FRP pultruded sections is their ability to replace traditional metal sections in areas where corrosion is a significant issue. For example, FRP pultruded sections are ideal for use in the marine industry, where exposure to saltwater can cause rapid deterioration of metal components. Similarly, in wastewater treatment plants, where metal structures may corrode due to chemical exposure, FRP pultruded sections provide a long-lasting and cost-effective alternative.

FRP pultruded sections also contribute to sustainability by offering a more energy-efficient and environmentally friendly material choice. They are non-toxic and recyclable, making them an excellent option for businesses looking to reduce their environmental footprint. With the growing emphasis on sustainable construction materials, FRP pultruded sections are playing an increasingly important role in shaping the future of construction and infrastructure development.

Benefits of FRP Pultruded Profiles and Sections

The growing popularity of FRP pultruded profiles and FRP pultruded sections can be attributed to the numerous advantages they offer over traditional materials like steel and aluminum. These composite materials are highly resistant to corrosion, making them ideal for industries and environments that involve exposure to moisture, chemicals, and harsh weather conditions. Unlike metal components that rust or corrode over time, FRP pultruded profiles and FRP pultruded sections remain intact, reducing maintenance costs and downtime.

Another key benefit of FRP pultruded profiles and FRP pultruded sections is their lightweight nature. The reduced weight of these profiles makes them easier to handle, transport, and install, resulting in lower labor costs and faster construction timelines. Additionally, FRP pultruded profiles and FRP pultruded sections have high tensile strength, allowing them to withstand heavy loads without the risk of bending or deformation.

The durability of FRP pultruded profiles and FRP pultruded sections means that they offer a long lifespan, contributing to their cost-effectiveness over time. These profiles are also low-maintenance, requiring minimal upkeep compared to traditional metal profiles. Their resistance to UV rays and extreme temperatures further enhances their suitability for outdoor and industrial applications.

Applications of FRP Pultruded Profiles and Sections

The versatility and durability of FRP pultruded profiles and FRP pultruded sections make them suitable for a wide range of applications. These profiles are commonly used in industries such as construction, infrastructure, transportation, and marine, where corrosion resistance, strength, and lightweight properties are crucial.

In the construction industry, FRP pultruded profiles and FRP pultruded sections are used in structural components, including beams, columns, and flooring systems. They are also ideal for producing architectural panels, handrails, and guardrails, providing both aesthetic appeal and functionality. The use of FRP pultruded profiles in construction has grown due to their resistance to corrosion and the ability to design custom profiles tailored to specific project requirements.

In the transportation sector, FRP pultruded profiles and FRP pultruded sections are used in the construction of railings, frames, and support structures for vehicles, trailers, and trains. Their lightweight nature makes them an ideal choice for reducing the overall weight of transportation vehicles, contributing to improved fuel efficiency and performance.

The marine industry also benefits greatly from FRP pultruded profiles and FRP pultruded sections. These profiles are used to build platforms, docks, walkways, and ladders, where traditional materials like steel are prone to rusting. FRP pultruded sections help to maintain structural integrity in harsh marine environments, ensuring long-lasting performance even in the most corrosive conditions.

FRP Pultruded Profiles FAQs

What are the main benefits of FRP pultruded profiles?

FRP pultruded profiles offer high strength, corrosion resistance, and low maintenance. They are lightweight, durable, and versatile, making them ideal for use in various industries, including construction and transportation.

How are FRP pultruded sections different from traditional metal sections?

Unlike traditional metal sections, FRP pultruded sections are resistant to corrosion, lightweight, and require less maintenance. They are also customizable, making them suitable for a wide range of applications where metal sections may fail due to rust or chemical exposure.

Can FRP pultruded profiles be used in outdoor environments?

Yes, FRP pultruded profiles are designed to withstand extreme weather conditions, UV exposure, and corrosion. They are an excellent choice for outdoor applications, especially in environments where traditional materials would degrade over time.

What industries commonly use FRP pultruded profiles and FRP pultruded sections?

FRP pultruded profiles and FRP pultruded sections are commonly used in construction, marine, transportation, and infrastructure industries. They are ideal for structural applications, such as beams, panels, and support structures.

Are FRP pultruded profiles and FRP pultruded sections recyclable?

Yes, FRP pultruded profiles and FRP pultruded sections are recyclable, making them an environmentally friendly material choice for various applications. They can be repurposed at the end of their life cycle to reduce waste and contribute to sustainability efforts.

In conclusion, FRP profiles, FRP pultruded profiles, and FRP pultruded sections are revolutionizing industries with their strength, durability, and versatility. With their corrosion resistance, lightweight nature, and long lifespan, these profiles are ideal for a wide range of applications, from construction to transportation. By choosing FRP pultruded profiles and FRP pultruded sections, businesses can enjoy long-term cost savings, improved performance, and greater sustainability.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNyheterNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNyheterNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNyheterNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNyheterNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNyheterNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNyheterNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNyheterNov.11,2025