loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ro frp vessel

Understanding RO FRP Vessels An Overview

Reverse osmosis (RO) technology has become a cornerstone in water purification and desalination processes, offering efficient solutions for producing potable water from brackish or seawater sources. One of the key components in these systems is the RO fiberglass-reinforced plastic (FRP) vessel. This article will explore the role, benefits, and advancements of RO FRP vessels in modern water treatment applications.

What Are RO FRP Vessels?

RO FRP vessels are specifically designed pressure vessels made from composite materials that provide strength and durability while being lightweight. The FRP construction consists of a polymer matrix reinforced with fiberglass, resulting in a material that is resistant to corrosion, chemical attack, and extreme temperatures. These properties make FRP vessels particularly suitable for RO systems, where they often house the RO membranes.

Importance of RO FRP Vessels

The effectiveness of reverse osmosis systems largely hinges on their ability to withstand high pressure and the harsh environments they are subjected to. RO FRP vessels fulfill this requirement by providing a lightweight solution that can support the operational pressures usually encountered in desalination processes, which can exceed 1000 psi (pounds per square inch).

Moreover, the corrosion resistance of FRP vessels plays a critical role in ensuring the longevity of the RO system. Traditional materials, such as metal, may suffer from rust and degradation when exposed to saline conditions or harsh chemicals used in membrane cleaning and maintenance. The robust nature of FRP alleviates these concerns, leading to lower maintenance costs and extended service life.

Advantages of Using RO FRP Vessels

1. Corrosion Resistance FRP vessels are immune to common corrosive agents found in seawater and wastewater, making them an ideal choice for various applications across the water treatment industry.

ro frp vessel

2. Weight Savings Their lightweight nature not only simplifies installation but also reduces shipping costs and labor expenses, as fewer resources are required for transportation and handling.

3. Design Flexibility FRP can be molded into various shapes and sizes, allowing for customized designs that fit specific project requirements while optimizing the use of space.

4. Thermal Stability FRP vessels can operate effectively across a wide range of temperatures, making them versatile for various climates and operational conditions.

5. Energy Efficiency The lightweight design results in less energy consumed during operation, contributing to overall cost savings in energy-intensive processes like reverse osmosis.

Innovations and Future Directions

The demand for clean water continues to rise globally, spurring innovations in water treatment technologies and materials. In the realm of RO FRP vessels, advancements in manufacturing techniques, such as automated winding processes and enhanced resin formulations, have led to improved performance and durability.

Moreover, ongoing research is focusing on integrating sensors and smart technologies into FRP vessels to monitor pressure, flow rates, and membrane conditions in real-time. Such innovations could pave the way for more efficient system management and predictive maintenance, ultimately enhancing the reliability and efficiency of RO systems.

Conclusion

In conclusion, RO FRP vessels represent a crucial component in the effectiveness of reverse osmosis technology. Their unique blend of strength, lightweight design, and corrosion resistance aligns perfectly with the demands of modern water treatment systems. As the world faces increasing challenges related to water scarcity, the continued development and optimization of RO FRP vessels will play an essential role in providing sustainable and efficient solutions for water purification globally.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

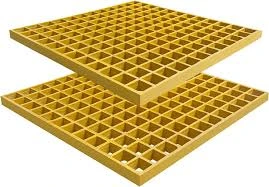

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025