loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

molded grating

Molded Grating An Innovative Solution for Modern Applications

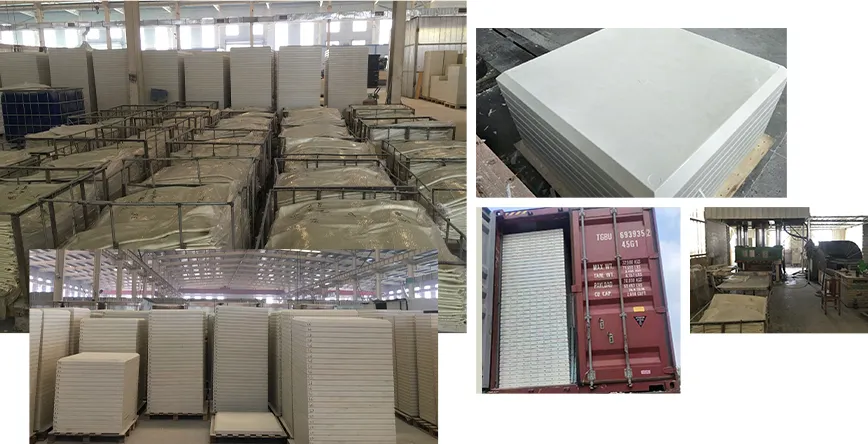

Molded grating, a versatile product formed through a process of molding resin and reinforcing fibers, has emerged as a significant innovation in various industrial and commercial applications. This type of grating is increasingly recognized for its durability, lightweight properties, and resistance to hazardous environmental conditions. As industries continue to seek materials that optimize safety and efficiency, molded grating offers a compelling solution.

The manufacturing process of molded grating involves the use of fiberglass reinforced plastic (FRP), which combines the strength of fiberglass with the flexibility of plastic. This combination results in a product that is not only robust but also resistant to corrosion, chemicals, and UV exposure. Such qualities make molded grating particularly suitable for environments that are wet, corrosive, or have high chemical exposure, like chemical plants, water treatment facilities, and marine applications.

One of the most notable advantages of molded grating is its safety features

. The grating is designed with slip-resistant surfaces, which are crucial in preventing accidents in workplaces that require walking or standing. Industries such as food processing, pharmaceuticals, and oil and gas are increasingly adopting molded grating to enhance safety protocols. The importance of slip resistance cannot be overstated, as it plays a vital role in reducing the risk of injuries on-site.molded grating

In addition to safety, molded grating is lightweight, making it easy to handle and install. This attribute not only reduces labor costs but also minimizes the structural load on buildings and other installations. Since molded grating can be cut and customized to fit specific applications, it offers flexibility in design, allowing for more efficient use of space and resources. This adaptability is particularly beneficial in renovation projects or in areas where traditional materials may be impractical.

Another key advantage is the longevity of molded grating. Unlike traditional materials such as steel and wood, molded grating does not rot, corrode, or degrade over time. This reduces maintenance costs significantly, making it an economically attractive option for many industries. The longevity of molded grating also contributes to sustainability by reducing the need for frequent replacements and minimizing landfill waste.

Despite its many benefits, the market for molded grating is not without competition. Traditional materials still hold a significant place in various sectors, primarily due to their historical use and familiarity. However, as more industries recognize the advantages of FRP molded grating, it is anticipated that demand will continue to grow. Manufacturers are investing in research and development to improve the performance and aesthetic appeal of molded grating, making it a more attractive choice for a wider range of applications.

In conclusion, molded grating stands out as an innovative solution that addresses the needs of modern industries. Its combination of safety, lightweight properties, durability, and low maintenance makes it an ideal choice for various applications. As industries evolve and prioritize efficiency and safety, molded grating is poised to become an increasingly important material in the future.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025