loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Profiles: Strong, Corrosion-Resistant & Lightweight Structural Solutions

The Evolution and Impact of FRP Profiles in Modern Construction

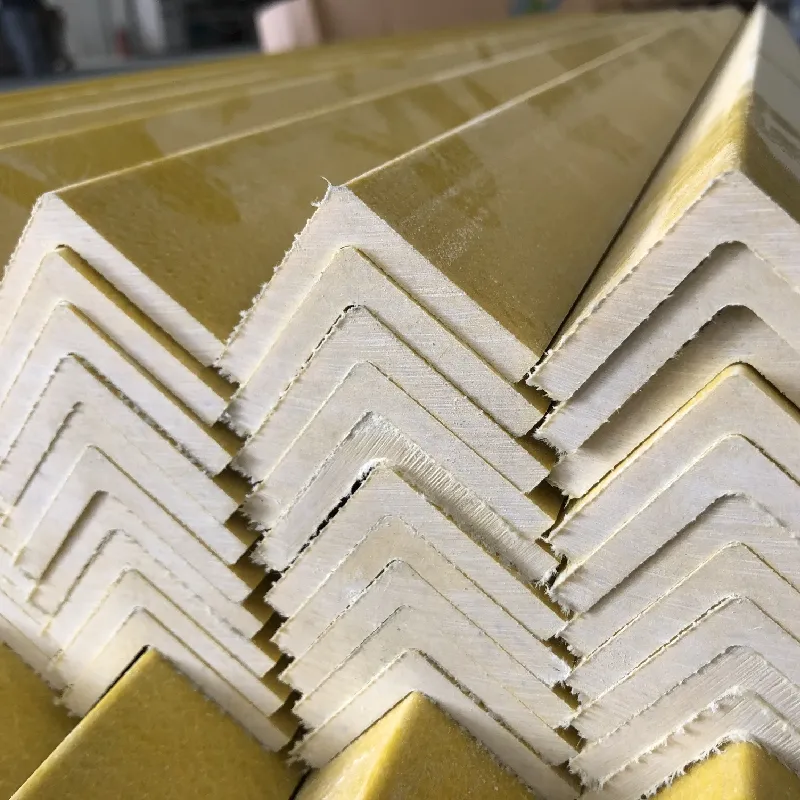

Fiber-reinforced polymer (FRP) composites are revolutionizing industries ranging from civil engineering and infrastructure to transportation and offshore drilling. Among the diverse forms of FRP products, frp profiles, especially pultruded sections like I-beams, channels, and angles, stand out for their exceptional strength-to-weight ratio, corrosion resistance, and electromagnetic transparency. These attributes make them ideal alternatives to traditional materials such as steel, aluminum, and timber in demanding environments. The global market for FRP composites is projected to grow at a Compound Annual Growth Rate (CAGR) of over 6% from 2023 to 2028, primarily driven by increasing demand from the construction, wind energy, and automotive sectors. This growth underscores a significant shift towards more sustainable, durable, and cost-effective material solutions, particularly for critical infrastructure projects where long-term performance and minimal maintenance are paramount. The strategic adoption of these advanced materials is not just a trend but a fundamental re-evaluation of structural engineering principles to enhance longevity and operational efficiency.

Our focus today is on High Strength FRP Pultruded Profile Fiberglass I Beams, a product engineered for superior performance in construction and industrial applications. These profiles are meticulously designed to meet the rigorous demands of structural integrity while offering the inherent benefits of composite materials. Unlike traditional metallic beams, fiberglass I-beams do not corrode, making them indispensable in chemical plants, wastewater treatment facilities, and marine environments. Their non-conductive nature provides enhanced safety in electrical substations and railway applications. Furthermore, the lightweight characteristic simplifies transportation and installation, leading to reduced labor costs and faster project completion times. This blend of robustness, versatility, and economic advantage positions high-strength frp profiles as a cornerstone for future-proof construction and infrastructure development.

Precision Manufacturing: The Pultrusion Process Unveiled

The superior performance of fiberglass I-beams and other frp profiles is largely attributed to the pultrusion manufacturing process, a continuous and automated method that ensures consistent quality and high mechanical properties. This process begins with large creels holding continuous glass fiber rovings and mats. These fibers, acting as the reinforcement, are pulled through a resin bath where they are thoroughly impregnated with a thermosetting resin system, typically polyester, vinyl ester, or epoxy, often combined with various additives such as UV inhibitors, fire retardants, and pigments. The choice of resin dictates many of the final product's properties, including chemical resistance, temperature tolerance, and mechanical strength. For high-strength applications, vinyl ester resins are frequently chosen due to their excellent corrosion resistance and robust mechanical performance.

Following impregnation, the saturated fibers enter a heated die. This die is precisely shaped to form the desired profile, such as an I-beam, channel, or tube. As the material passes through the heated die, the resin undergoes a polymerization process, curing and solidifying around the fibers. This continuous pulling action, combined with precise temperature control within the die, ensures a uniform, void-free composite structure with high fiber volume fraction. The result is a profile with exceptional longitudinal strength, stiffness, and dimensional stability. Post-curing, the rigid profile is cut to the specified length by a flying cut-off saw. Quality control checks are performed at various stages, including raw material inspection, in-process monitoring of resin saturation and curing, and final product testing for mechanical properties (e.g., tensile strength, flexural strength, shear strength) and dimensional accuracy. Adherence to international standards like ASTM D7290 (Standard Practice for Evaluating Pultruded Fiberglass Reinforced Plastic Structural Products) and ISO 9001 (Quality Management System) ensures the reliability and longevity of these crucial structural components, typically offering a service life exceeding 50 years under normal conditions, significantly reducing lifecycle costs.

Technical Specifications and Performance Advantages

The engineering excellence of high-strength frp profiles is best understood through their robust technical parameters. These profiles are designed to offer a unique combination of physical and chemical properties that surpass traditional materials in specific applications. Key performance indicators include high tensile and flexural strength, excellent chemical resistance to a wide range of acids, alkalis, and solvents, and a low thermal conductivity that contributes to energy efficiency in structures. Unlike steel, FRP does not conduct electricity, making it safe for environments with electrical hazards. Its light weight simplifies handling and installation, reducing the need for heavy machinery and extensive labor, which directly translates to project cost savings.

| Parameter | Typical Value for FRP Pultruded I-Beam | Comparison to Steel (Approx.) |

|---|---|---|

| Tensile Strength (Longitudinal) | 300-600 MPa (43-87 ksi) | 400-690 MPa (Structural Steel) |

| Flexural Strength (Longitudinal) | 350-700 MPa (50-100 ksi) | Similar or higher by weight |

| Modulus of Elasticity (Longitudinal) | 20-40 GPa (3-6 Msi) | 200 GPa (30 Msi) (Lower stiffness, requires different design) |

| Specific Gravity (Density) | 1.8-2.0 g/cm³ | 7.85 g/cm³ (Approx. 1/4 the weight of steel) |

| Thermal Conductivity | 0.2-0.4 W/m·K | 40-50 W/m·K (Excellent insulator) |

| Corrosion Resistance | Excellent (Unaffected by most chemicals) | Prone to rust, requires coatings |

| Electrical Conductivity | Non-conductive | Highly conductive |

While the modulus of elasticity for FRP is lower than steel, requiring different design approaches (e.g., larger cross-sections or different connection details to manage deflection), its other properties offer significant advantages in specific applications. The combination of high strength, low weight, and inherent resistance to environmental degradation makes frp profiles a highly attractive and durable solution for challenging structural requirements. Furthermore, the material's excellent fatigue resistance and impact absorption capabilities contribute to a longer service life and reduced maintenance cycles compared to traditional materials, translating into substantial long-term cost savings and improved operational reliability for end-users.

Diverse Applications Across Key Industries

The versatility of high-strength frp profiles allows for their deployment across a broad spectrum of industries, solving critical challenges where traditional materials fall short. In the Petrochemical Industry, FRP grating, platforms, and structural supports are indispensable due to their unparalleled resistance to corrosive chemicals, reducing the need for constant maintenance and replacement in highly aggressive environments. Similarly, in Metallurgical Plants, where operations involve extreme temperatures and corrosive byproducts, FRP components offer durability and safety, particularly in areas exposed to acids used in pickling lines or electroplating processes. Their non-conductive nature also prevents stray current corrosion.

The Water and Wastewater Treatment sector heavily relies on FRP for everything from walkways, handrails, and tank covers to entire structural systems. The inherent resistance to chlorine, sulfates, and other aggressive chemicals found in municipal wastewater ensures the longevity and integrity of these critical facilities. For instance, pump stations, clarifiers, and filter presses benefit immensely from FRP's non-corrosive properties, ensuring operational continuity and significantly lower lifecycle costs compared to steel, which would require frequent painting and repair. In Electrical Substations and Power Plants, the non-conductive properties of FRP provide a crucial safety advantage, preventing electrical shorts and ensuring the safety of personnel working near live components. FRP ladders, platforms, and cable trays are standard in these facilities.

Beyond these, frp profiles find extensive use in Marine and Offshore Structures, resisting saltwater corrosion and providing lightweight, durable solutions for docks, jetties, and ship components. In Telecommunications, their electromagnetic transparency prevents interference with sensitive electronic equipment, making them ideal for radar and antenna support structures. Furthermore, in Bridge Decks and Building Construction, FRP beams contribute to reduced dead load, longer spans, and enhanced durability against environmental factors. The energy-saving aspect comes from their low thermal conductivity, which can improve the thermal performance of building envelopes, leading to reduced heating and cooling costs over the building's lifespan. This wide range of applications underscores FRP's role as a material of choice for engineers and specifiers seeking long-term value and high performance in challenging environments.

Custom Solutions and Manufacturer Expertise

Selecting the right manufacturer for frp profiles is crucial for ensuring product quality, performance, and long-term reliability. A reputable manufacturer differentiates itself through adherence to stringent quality control standards, such as ISO 9001 certification, and by offering comprehensive testing data in accordance with relevant ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute) standards. They possess a deep understanding of composite materials science and engineering, enabling them to provide expert guidance on material selection, structural design, and installation techniques. This expertise is particularly valuable when standard solutions do not perfectly fit a project's unique requirements, necessitating custom design and manufacturing.

Customization capabilities are a hallmark of a leading FRP profile manufacturer. This includes tailoring specific resin systems to combat particular chemical environments, incorporating fire-retardant additives for enhanced safety, or designing unique cross-sections and dimensions to meet precise structural loads and spatial constraints. For example, a project requiring an exceptionally long span or a specific load-bearing capacity might necessitate a custom-engineered I-beam geometry or a higher fiber volume fraction. Our product, the High Strength FRP Pultruded Profile Fiberglass I Beam, can be optimized for various scenarios, demonstrating our commitment to providing bespoke solutions. Furthermore, a manufacturer's ability to provide comprehensive pre-sale technical support, including CAD drawings and structural analysis, and post-sale service, such as installation guidelines and maintenance recommendations, significantly adds to the project's success and client satisfaction. We believe in partnering with our clients to deliver solutions that are not only high-performing but also precisely aligned with their operational goals and industry-specific challenges, ensuring that every fiberglass I-beam delivers maximum value and operational efficiency.

Ensuring Trust: Quality, Support, and Warranty

Trust is built on transparency, reliability, and robust support systems. For critical infrastructure components like frp profiles, this translates into clear certifications, dependable delivery, comprehensive warranties, and responsive customer service. Our commitment to quality is evidenced by adherence to international standards like ISO 9001 and extensive product testing. Each batch of our High Strength FRP Pultruded Profile Fiberglass I Beams undergoes rigorous testing for mechanical properties, including tensile strength, flexural strength, and shear strength, ensuring that every product meets or exceeds specified performance criteria. Test reports and material safety data sheets are readily available to provide complete transparency regarding our product's composition and performance characteristics, empowering engineers and procurement specialists to make informed decisions with confidence.

Frequently Asked Questions (FAQ)

- What is the typical lead time for FRP profiles?

Delivery cycles vary based on order volume and customization requirements. For standard FRP I-beams, lead times typically range from 2 to 4 weeks. Custom profiles or large orders may require 6 to 8 weeks. We work closely with clients to establish realistic timelines and offer expedited options when feasible, ensuring projects stay on schedule. - What is the expected service life of FRP profiles?

Under normal operating conditions and proper installation, our FRP pultruded profiles are designed for a service life exceeding 50 years. Their inherent resistance to corrosion, UV degradation (with appropriate additives), and fatigue contributes significantly to this extended lifespan, minimizing replacement costs and downtime. - Are FRP profiles fire resistant?

Standard FRP is not inherently fireproof, but it is formulated to be fire retardant. Our profiles can be manufactured with specialized resin systems and additives to achieve specific fire ratings (e.g., ASTM E84 Class I flame spread), crucial for applications where fire safety is paramount. Please specify fire resistance requirements for appropriate material selection. - What warranty do you offer on your products?

We stand behind the quality of our High Strength FRP Pultruded Profile Fiberglass I Beams with a comprehensive warranty against manufacturing defects and material failures under normal use. Specific warranty terms and conditions are provided with each quotation, reflecting our confidence in the durability and performance of our products. Our customer support team is available to assist with any post-purchase inquiries, ensuring a smooth and satisfactory experience for our valued clients.

Our commitment extends beyond product delivery to providing comprehensive customer support, including technical assistance, installation guidelines, and post-sales service. We aim to foster long-term partnerships by ensuring that our clients receive not just a product, but a complete solution backed by expertise, reliability, and unwavering support. This holistic approach ensures that every project incorporating our frp profiles benefits from maximized operational uptime and minimized lifecycle costs.

References

- Journal of Composite Materials

- Composites Science and Technology

- Fiber Reinforced Polymer (FRP) Composites in Construction: A Review

- ASTM International Standards and Publications

- International Journal of Structural Engineering

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025