loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

jan . 25, 2025 22:09

Back to list

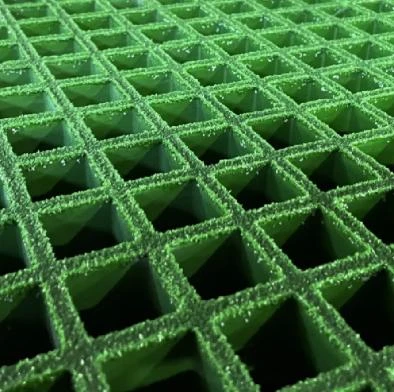

frp micro mesh grating

Fiber reinforced plastic (FRP) rods represent a substantial advancement in materials engineering, offering remarkable advantages over traditional materials, which makes them an essential component in diverse industries such as construction, automotive, and aerospace. This article elucidates the attributes, applications, and benefits of FRP rods, underscoring their growing importance in modern engineering solutions.

The implementation of FRP rods has been bolstered by continued advancements in materials science. Innovative manufacturing techniques have led to improved synchronization between the polymer matrix and fiber reinforcement, producing composites with superior load-bearing capabilities and resistance to thermal expansion. For expert practitioners, understanding these advancements opens the door to more sustainable and economically viable engineering practices. Yet, reliability in using FRP rods extends beyond their inherent properties. The credibility of the product is largely contingent on the producer's expertise and adherence to quality standards. Leading manufacturers of FRP materials not only ensure rigorous compliance with industry norms but also invest in continuous research and development, constantly pushing the boundaries of what these advanced materials can achieve. Field applications have demonstrated the efficacy and durability of FRP rods. Real-world case studies reveal significant improvements post-deployment, with FRP solutions providing not only robustness but also economic benefits. A notable example is the use of fiberglass rods in the reinforcement of power transmission towers, where they have consistently delivered high performance under duress, showcasing minimal wear and tear over extended periods. These real-world endorsements further enhance the trustworthiness of FRP rods as reliable alternatives to their metallic counterparts. The educational material regarding FRP rod applications should always emphasize proper installation practices and potential limitations. While advantageous in many respects, FRP rods require specific handling and setup to realize their full potential. Engineering teams must ensure compatibility with overall design criteria and environmental conditions, underscoring the importance of expertise in their application. In conclusion, fiber reinforced plastic rods offer groundbreaking benefits that align with modern engineering demands, driven by their exceptional mechanical properties, versatility, and resistance to environmental stresses. As industries rapidly evolve towards materials that offer enhanced performance with sustainability, FRP rods stand out as not only a feasible solution but a strategic innovation paving the future of materials engineering. Expertise in their application coupled with ongoing industry advancements promises continued success and trust in their use across a multitude of disciplines.

The implementation of FRP rods has been bolstered by continued advancements in materials science. Innovative manufacturing techniques have led to improved synchronization between the polymer matrix and fiber reinforcement, producing composites with superior load-bearing capabilities and resistance to thermal expansion. For expert practitioners, understanding these advancements opens the door to more sustainable and economically viable engineering practices. Yet, reliability in using FRP rods extends beyond their inherent properties. The credibility of the product is largely contingent on the producer's expertise and adherence to quality standards. Leading manufacturers of FRP materials not only ensure rigorous compliance with industry norms but also invest in continuous research and development, constantly pushing the boundaries of what these advanced materials can achieve. Field applications have demonstrated the efficacy and durability of FRP rods. Real-world case studies reveal significant improvements post-deployment, with FRP solutions providing not only robustness but also economic benefits. A notable example is the use of fiberglass rods in the reinforcement of power transmission towers, where they have consistently delivered high performance under duress, showcasing minimal wear and tear over extended periods. These real-world endorsements further enhance the trustworthiness of FRP rods as reliable alternatives to their metallic counterparts. The educational material regarding FRP rod applications should always emphasize proper installation practices and potential limitations. While advantageous in many respects, FRP rods require specific handling and setup to realize their full potential. Engineering teams must ensure compatibility with overall design criteria and environmental conditions, underscoring the importance of expertise in their application. In conclusion, fiber reinforced plastic rods offer groundbreaking benefits that align with modern engineering demands, driven by their exceptional mechanical properties, versatility, and resistance to environmental stresses. As industries rapidly evolve towards materials that offer enhanced performance with sustainability, FRP rods stand out as not only a feasible solution but a strategic innovation paving the future of materials engineering. Expertise in their application coupled with ongoing industry advancements promises continued success and trust in their use across a multitude of disciplines.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025