loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Covered Grating: Anti-Slip, Corrosion-Resistant FRP

If you spend time in chemical plants, water treatment corridors, or even on salty marina piers, you’ve probably stood on Covered Grating without thinking twice. To be honest, that’s the point: reliable footing, quiet performance, and no drama when things get wet or corrosive.

What’s driving the switch to FRP?

Across the industry, steel is ceding ground to FRP because of lifecycle math. Fewer shutdowns for repainting, no rust bleed-through, and—surprisingly—lighter structures that still meet load. Many customers say the 30% higher stiffness of Covered Grating versus open mesh makes trolleys and carts feel steadier. ESG teams like the longer service life (often ≈25–40 years, real-world use may vary), and maintenance crews like not smelling solvents every spring.

Product snapshot: Corrosion Resistant and Slip Resistant FRP GRP Fiberglass Covered Grating

| Panel sizes | ≈ 1000×3000 mm, 1220×3660 mm; custom cuts available |

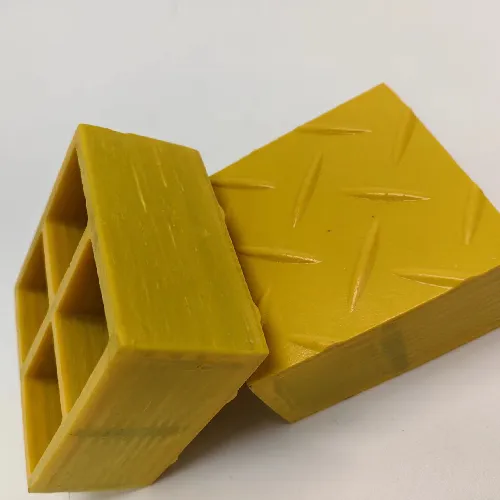

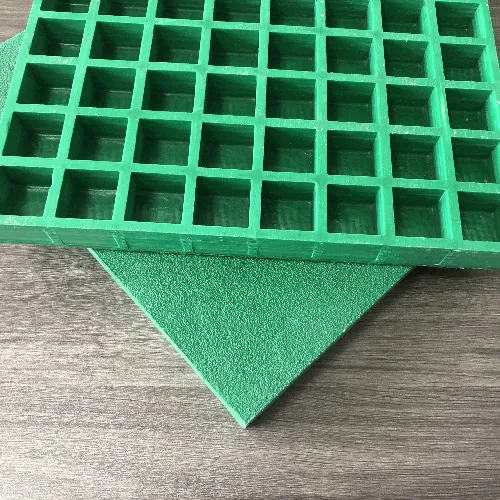

| Thickness options | 25, 30, 38 mm typical; cover plate 3–5 mm (gritted or smooth) |

| Resin systems | Orthophthalic, Isophthalic, Vinyl ester, Phenolic (for higher fire/chem) |

| Slip resistance | Gritted top; wet dynamic CoF often ≥0.60 (site results vary) |

| Fire & UV | ASTM E84 Class 1 (resin-dependent); UV tested per ASTM G154 |

| Compliance | ISO 9001 factory QA; load tests to ASTM D790; design per ISO 14122 walkways |

| Origin | No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China |

How it’s made (quick shop-floor view)

Materials: glass rovings/mats, corrosion-resistant resins, mineral grit, UV stabilizers. Method: molded FRP grating with an integrally bonded cover plate, co-cured as one piece; gritted top broadcast and sealed during gel stage. QC: barcol hardness, fiber-to-resin ratio, flexural per ASTM D790, burn/smoke per ASTM E84, salt spray/UV aging checks. Service life: around 25–40 years depending on resin choice, UV exposure, and chemicals. I guess that’s why crews keep replacing old steel with Covered Grating in brine rooms and clarifier decks.

Where it fits best

Wastewater headworks, chemical dosing skids, food & beverage plants (avoids drips below), battery rooms, coastal platforms, power plant scrubbers, data center rooftops for neat cable crossings. The solid top of Covered Grating controls odors and prevents debris fall-through; narrow-heel trips are far less common.

Vendor landscape (field-notes version)

| Vendor | Strengths | Lead time | Customization | Certs | Price level |

| ZJ Composites | Broad resin menu; solid QA; flexible cuts | ≈2–4 weeks | Colors, grit grade, conductive options | ISO 9001; 3rd-party tests | Value-oriented |

| US-based Brand | Large stock; strong documentation | Stock–6 weeks | Moderate | ISO; FM options | Higher |

| EU-based Brand | CE focus; marine pedigree | ≈4–8 weeks | Color and fire grades | EN/CE docs | Premium |

Customization tips

Pick vinyl ester for harsh acids; phenolic for tighter fire/smoke envelopes; specify 5 mm cover with coarse grit for wet ramps; request edge banding and predrilled fixings. For ESD-sensitive spaces, ask about conductive Covered Grating systems and earthing points.

Real-world notes

Case 1: A Southeast Asia beverage plant replaced rusting checker plate; the new Covered Grating cut slip incidents to near-zero during CIP washdowns (maintenance team’s words, not mine). Case 2: A coastal marina swapped timber planks for FRP; two monsoon seasons in, the grit still bites and no blackening.

Testing & paperwork to cite in specs: ASTM D790 (flexural), ASTM D638 (tensile), ASTM D695 (compressive), ASTM E84 (flame/smoke), ASTM G154 (UV), ISO 14122 (walkways), plus site slip tests (e.g., pendulum/BPN). It seems that when these are named upfront, procurement moves faster.

- ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials (ASTM International).

- ASTM D790: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics (ASTM International).

- ASTM G154: Standard Practice for UV Exposure of Nonmetallic Materials (ASTM International).

- ISO 14122-2: Safety of machinery — Permanent means of access to machinery — Working platforms and walkways (ISO).

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025