loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

feb . 08, 2025 06:46

Back to list

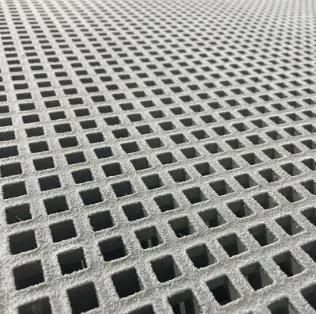

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Purchasing bar grating, whether for an industrial platform, safety walkway, or an architectural project, can seem daunting. Ensuring you get high-quality materials that meet safety standards and longevity expectations requires understanding various product specifications and applications.

An integral part of acquiring bar grating is assessing the manufacturer’s credibility. Engage with manufacturers or suppliers that adhere to industry standards such as the NAAMM (National Association of Architectural Metal Manufacturers) or the ASTM (American Society for Testing and Materials). This certification ensures that products are rigorously tested for quality and safety. Additionally, customer testimonials and case studies can offer insights into product performance in real-world applications. Seeking expert consultancy can further enhance the purchasing process. Professionals with extensive experience in structural engineering or industrial safety can provide invaluable guidance. Their insights can tailor grating solutions to specific structural, aesthetic, or safety requirements, minimizing both upfront costs and long-term maintenance expenses. Ensuring that installation follows best practices also enhances the bar grating’s functionality and longevity. Improperly installed grating can lead to uneven loads, increased wear, and potential safety hazards. Installation should ideally be conducted by experienced professionals who can guarantee that the grating integrates seamlessly with existing structures and complies with occupational safety standards. Incorporating sustainability into your purchase decision can sustain long-term environmental and financial benefits. Many manufacturers now offer recyclable grating options using sustainable materials without compromising durability and quality. Investing in eco-friendly grating solutions aligns with modern environmental considerations and could significantly enhance a company’s reputation in adherence to sustainable practices. To summarize, selecting bar grating for sale necessitates a well-rounded approach emphasizing material selection, load capacity, environmental considerations, and manufacturer credibility. Choosing the right bar grating can elevate project safety and efficiency, reduce maintenance costs, and contribute positively to sustainability goals. Expert consultation and adherence to industry standards form the backbone of a trustworthy purchase, ensuring that each piece of grating meets the specific needs and expectations of its intended application.

An integral part of acquiring bar grating is assessing the manufacturer’s credibility. Engage with manufacturers or suppliers that adhere to industry standards such as the NAAMM (National Association of Architectural Metal Manufacturers) or the ASTM (American Society for Testing and Materials). This certification ensures that products are rigorously tested for quality and safety. Additionally, customer testimonials and case studies can offer insights into product performance in real-world applications. Seeking expert consultancy can further enhance the purchasing process. Professionals with extensive experience in structural engineering or industrial safety can provide invaluable guidance. Their insights can tailor grating solutions to specific structural, aesthetic, or safety requirements, minimizing both upfront costs and long-term maintenance expenses. Ensuring that installation follows best practices also enhances the bar grating’s functionality and longevity. Improperly installed grating can lead to uneven loads, increased wear, and potential safety hazards. Installation should ideally be conducted by experienced professionals who can guarantee that the grating integrates seamlessly with existing structures and complies with occupational safety standards. Incorporating sustainability into your purchase decision can sustain long-term environmental and financial benefits. Many manufacturers now offer recyclable grating options using sustainable materials without compromising durability and quality. Investing in eco-friendly grating solutions aligns with modern environmental considerations and could significantly enhance a company’s reputation in adherence to sustainable practices. To summarize, selecting bar grating for sale necessitates a well-rounded approach emphasizing material selection, load capacity, environmental considerations, and manufacturer credibility. Choosing the right bar grating can elevate project safety and efficiency, reduce maintenance costs, and contribute positively to sustainability goals. Expert consultation and adherence to industry standards form the backbone of a trustworthy purchase, ensuring that each piece of grating meets the specific needs and expectations of its intended application.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025