loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Trusted FRP Grating Suppliers | Custom, Corrosion-Resistant

Frp Grating Suppliers is a key solution in the Architecture and Building Materials industry, specifically within Composite material products and fiberglass grating. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Frp Grating Suppliers Overview

- Benefits & Use Cases of Frp Grating Suppliers in fiberglass grating

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Architecture and Building Materials

- Conclusion on Frp Grating Suppliers from Zhaojia Composites Co., Ltd

Frp Grating Suppliers Overview

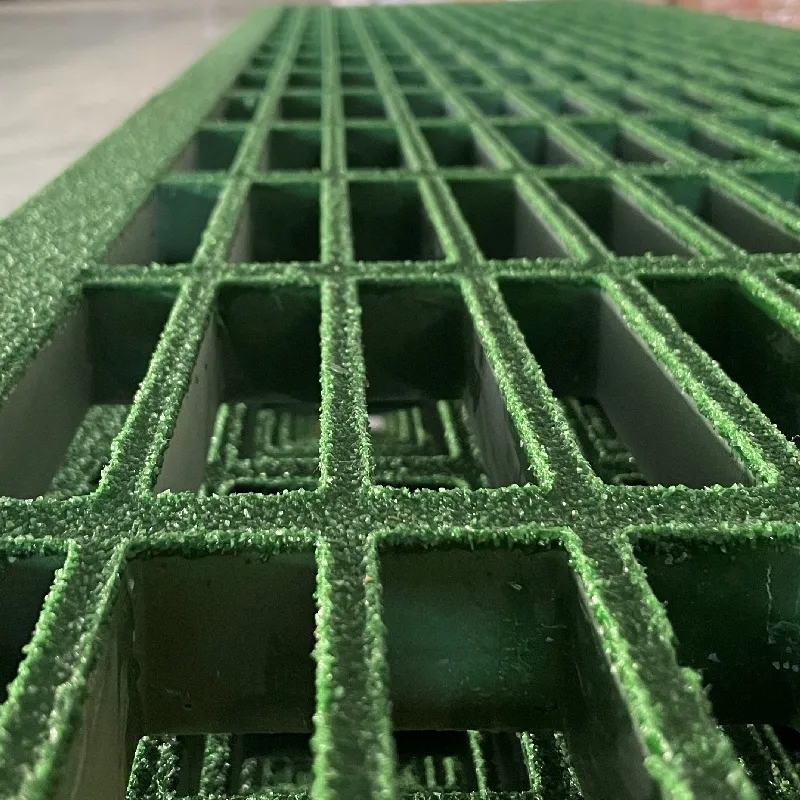

FRP (fiber-reinforced polymer) grating is a high-strength, corrosion-resistant alternative to steel and aluminum for walkways, platforms, trench covers, and access systems. In the Architecture and Building Materials sector—especially within composite material products—FRP grating is prized for its non-conductive, non-magnetic performance and superior lifecycle value. Molded fiberglass rectangular mesh grating delivers uniform bi-directional load distribution, excellent impact absorption, and reliable slip resistance with gritted surfaces. Typical specifications include standard thickness ranges (e.g., 25–50 mm), common mesh patterns, and resin systems such as isophthalic or vinyl ester for enhanced chemical resistance. FRP gratings can be designed to meet relevant performance criteria for industrial walkways and are valued in water treatment, marine, chemical processing, food and beverage, and power facilities.

Zhaojia Composites Co., Ltd manufactures molded fiberglass rectangular mesh grating with consistent fiber wet-out and resin distribution to achieve dependable mechanical properties across panels. As one of the experienced FRP grating suppliers, Zhaojia offers engineered support on load tables, span selection, and surface finishes. For applications requiring higher corrosion resistance, vinyl ester options and UV-stabilized colors can be specified. Explore product details here: Moulded Fiberglass Rectangular Mesh Grating.

Benefits & Use Cases of Frp Grating Suppliers in fiberglass grating

Leading frp grating suppliers support critical B2B environments where uptime and safety are non-negotiable. In wastewater treatment plants, FRP grating resists hydrogen sulfide and moisture; in chemical processing, it withstands splash zones and fumes; and in marine or coastal facilities, it defies chloride attack and underfoot corrosion. Architects and EPCs also specify FRP for rooftops, HVAC platforms, catwalks, mezzanines, stair treads, and trench covers due to its lightweight and minimal maintenance profile. Compared to metallic systems, FRP typically installs faster (no hot works), helps reduce structural dead load, and maintains slip resistance with embedded quartz-grit surfaces.

- Corrosion and chemical resistance for aggressive environments.

- Non-conductive, non-sparking, and thermally stable for safer access systems.

- High strength-to-weight ratio, enabling longer spans with lighter support steel.

- Durable slip-resistant surfaces tailored for wet or oily conditions.

Zhaojia Composites Co., Ltd brings application know-how to every project—from resin selection to surface finish and cut-to-size panels—helping decision makers meet performance, budget, and timeline targets. Their molded fiberglass rectangular mesh grating is engineered for consistent quality and dependable field performance across industrial and architectural use cases.

Cost, Maintenance & User Experience

Total cost of ownership favors FRP in corrosive or wet environments. While initial material pricing can be comparable to or slightly above galvanized steel, lifecycle costs are typically lower thanks to minimal maintenance, no repainting, and fewer corrosion-related shutdowns. Faster installation—without hot work permits and with lighter lifting requirements—can decrease labor costs and speed project schedules. Over a standard asset life, these savings often translate into compelling ROI, especially where exposure to chemicals, salt spray, or frequent washdowns accelerates metal degradation.

Customers in composite-heavy industries report steady underfoot traction from gritted FRP surfaces and appreciate the product’s dimensional stability across temperature swings. Facility managers note reduced inspection and coating cycles, while EHS teams value the non-conductive nature of FRP grating in electrical zones. Zhaojia Composites Co., Ltd supports owners and contractors with span guidance, panel optimization to reduce offcuts, and tailored packaging for efficient handling—enhancing user experience from specification through installation and service life.

Sustainability & Market Trends in Architecture and Building Materials

Global infrastructure is trending toward materials that enable longer service intervals, safer operations, and lower embodied impacts. FRP grating aligns with these goals: its light weight can reduce transport emissions and supporting steel tonnage; its corrosion resistance extends asset life, lowering replacement frequency and waste; and its durable slip-resistant finish supports safety KPIs. As regulations continue to emphasize worker protection and asset integrity, specifiers are replacing metals in corrosive zones with FRP to meet performance and compliance objectives. In many projects, FRP grating can be specified to meet relevant fire performance and walkway safety standards, depending on resin system and design.

Zhaojia Composites Co., Ltd positions sustainability as practical longevity: engineering molded fiberglass rectangular mesh grating for long-term service reduces maintenance activities and associated environmental impacts. The company focuses on consistent quality, material efficiency, and application-driven design support—helping clients achieve durable outcomes that align with modern decarbonization and resiliency strategies across architecture, industrial plants, and marine infrastructure.

Conclusion on Frp Grating Suppliers from Zhaojia Composites Co., Ltd

For B2B leaders in the Architecture and Building Materials space, FRP grating offers a proven balance of safety, durability, and lifecycle value. Partnering with experienced frp grating suppliers ensures the right resin, mesh, thickness, and finish for each application. Zhaojia Composites Co., Ltd delivers molded fiberglass rectangular mesh grating that meets demanding industrial and architectural requirements with consistent quality and responsive technical support.

- Elevate performance and reduce maintenance with engineered fiberglass grating.

- Rely on Zhaojia Composites Co., Ltd for dependable products and application expertise.

- Strong CTA: Contact us: email: admin@zjcomposites.com — Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025