loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of FRP Pultruded Gratings in Construction and Industrial Design

Understanding FRP Pultruded Gratings Their Benefits and Applications

FRP (Fiber Reinforced Polymer) pultruded gratings have become increasingly popular in various industries due to their unique properties and advantages over traditional materials. This article aims to explore the characteristics, benefits, and applications of FRP pultruded gratings, providing insight into why they are the material of choice for many engineers and architects.

What Are FRP Pultruded Gratings?

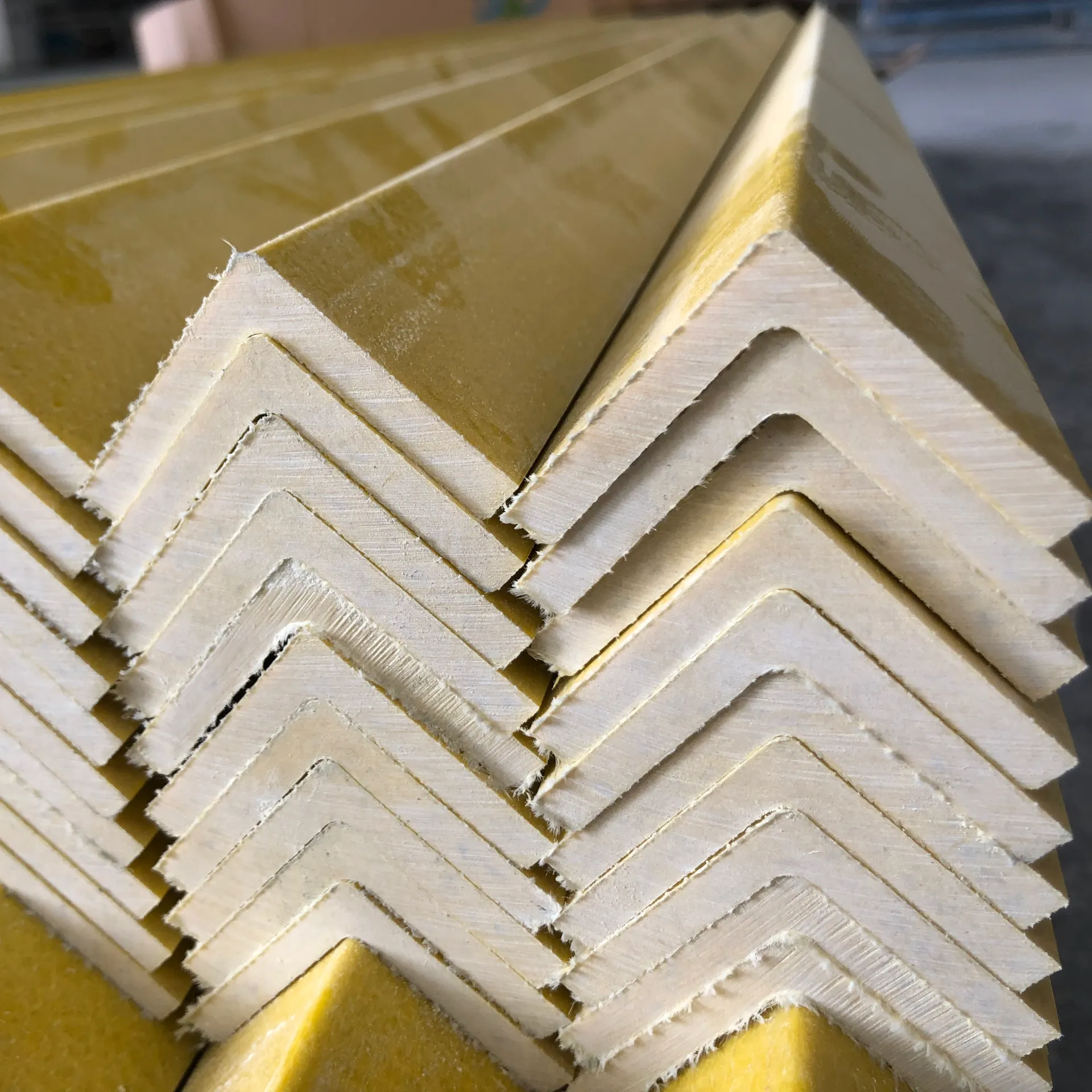

FRP pultruded gratings are composite materials produced through a continuous manufacturing process known as pultrusion. This process involves pulling fibers (typically glass or carbon fibers) through a resin bath and then through a heated die to create a solid, rigid structure. The resulting gratings come in various shapes and sizes, making them versatile for different applications.

The primary components of FRP pultruded gratings are the resin matrix and the reinforcing fibers. The resin provides durability and corrosion resistance, while the fibers provide tensile strength. Together, these elements create a product that can withstand harsh environmental conditions and heavy loads.

Key Benefits of FRP Pultruded Gratings

1. Corrosion Resistance One of the most notable advantages of FRP gratings is their resistance to corrosion. Unlike traditional materials such as steel, which can rust and degrade over time, FRP can withstand exposure to various chemicals and harsh environments, making it ideal for use in chemical processing plants, wastewater treatment facilities, and coastal areas.

2. Lightweight FRP pultruded gratings are significantly lighter than their metal counterparts. This lightweight nature not only reduces transportation costs but also makes installation easier and more cost-effective. The aesthetic appeal of FRP gratings also contributes to their popularity, as they can be designed in various colors and finishes.

3. High Strength-to-Weight Ratio The combination of lightweight materials and strong reinforcing fibers gives FRP gratings a high strength-to-weight ratio. This property allows them to support heavy loads while remaining easy to handle. As a result, they are suitable for use in platforms, walkways, and other load-bearing applications.

4. Electrical Insulation FRP materials are non-conductive, which makes them an excellent choice for electrical applications. They provide safety in environments where electrical hazards are a concern, making them suitable for use in power plants and substations.

frp pultruded gratings

5. Reduced Maintenance Due to their corrosion resistance and durability, FRP pultruded gratings require minimal maintenance compared to traditional materials. This characteristic not only reduces lifecycle costs but also minimizes operational downtime.

Applications of FRP Pultruded Gratings

FRP pultruded gratings are versatile and can be used in various sectors, including

- Industrial Manufacturing They provide safe and reliable walking surfaces in manufacturing environments, especially in areas exposed to chemicals and heavy machinery.

- Water and Wastewater Treatment Due to their resistance to corrosion and chemical exposure, FRP gratings are widely used in water treatment plants and wastewater facilities.

- Infrastructure FRP gratings are used in pedestrian walkways, bridges, and platforms, offering a durable and lightweight alternative to steel or aluminum.

- Marine Applications Their resistance to saltwater and harsh marine environments makes them ideal for use in docks, piers, and other coastal structures.

- Food and Beverage Industry FRP gratings are non-porous and can be easily cleaned, making them suitable for food processing plants, breweries, and dairy facilities.

Conclusion

FRP pultruded gratings are transforming the way industries approach construction and design. Their superior properties, such as corrosion resistance, lightweight nature, and high strength, make them an attractive alternative to traditional materials. As industries continue to seek durable and cost-effective solutions, the demand for FRP gratings is expected to grow, paving the way for further innovation in composite materials. Whether for industrial applications, infrastructure projects, or special environments, FRP pultruded gratings offer a modern solution that meets the challenges of today's demands.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025