loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

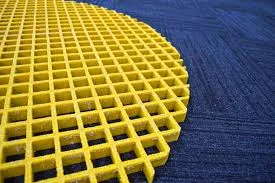

The complete guide to FRP gratings

The complete guide to FRP gratings

What are FRP gratings?

FRP grating is kind of material that mostely used in industrial or public space applications, such as walkways, platforms, catwalks, stair treads, trench covers etc. Are you in need of FRP gratings for your project? if you need to choose a right material for your project, then you need to be familiar with the different types available in the market, FRP ( Fibre-reinforced plastic )is a strong, light weight, non-corrosive material that replaces

steel, wood, and aluminum in various applications. This blog post will provide a comprehensive guide to FRP gratings, so you can make an informed decision for your project.

Available size of FRP grating

The dimension for FRP gratings need to choose mainly include mesh size and height, panel size

mesh size is fixed, panel size can be cut to different pieces.

Mesh size: 38x38mm, 40x40mm, 19x19mm/38x38, 50x50mm, 25x100mm

Panel size: 1220x3660mm, 1220x2440mm, 1000x4040mm, 1000x2000mm, Customized

Available surface type of FRP gratings

Surface type of grating inculde flat smooth type, and anti-slip type can choose both concave or gritted type.

Available top cover of FRP gratings

Grating also has top cover type, named checker plate.

Available Edge Type of FRP Gratings

The FRP Grating is made by molded process, it is finish with a fixed size panel, but if customer request the panel size is small than fixed size, we can provide cutting service, after cutting, the edge of grating maybe is different shape, before order, we need to confirm if customer has demands for edge of fiber gratings.

Available Color Type of FRP Gratings

Color for FRP Gratings include yellow, green, blue, black, red, grey and so on, also can accept customized color.

Benefits of FRP Gratings

Anti-corrosion

Light weight & easy to handle

Long product life & maintenance free

Non-conducting & chemical resistant

Slip resistant

Fire retardant

Manufacture Process of FRP Gratings

Step 1:Mixing Resin and Other Raw Material

Put the resin into mixing tank, such as GB196 resin, also with filler, color paste, stir evenly.

Step 2:Put slurry Into Mold

Put the welled mixed raw material slurry into the mold, make it smooth by a scraper.

Step 3:Layout Fiberglass Yarn

Layout fiberglass yarn into the mold, Distribute yarn evenly into the grid.

Step 4: Press Mold

Press the mold, Make the raw material more more firmly fixed together, reduce air holes.

Step 5:Heating&Solidify

Heating the mold to solidify the grating.

Step 6:Mold Release(Ejection)

After fully cured, Ejector pin push out the grating from the mold.

Step 7:Surface Grinding and varnishing

Do the surface grinding step to make the surface smooth, and varnish it by brush.

Step 8:Cutting

According to customer size request, cutting it to different size.

Step 9:Packing and Loading

Packing the finish grating by plastic wrap and carton plate, loading and transport.

How to distinguish quality FRP gratings

1)Selection of raw materials.

The raw materials used by the FRP grid are resin, FRP fiber wire, filling calcium powder is arranged in a ratio of 1:1:1. The high quality FRP grid is made of high quality resin: unsaturated o-benzene resin 196, colorless and transparent. Low viscosity, low heat release, low shrinkage, high speed curing, high compatibility, bright gloss. The production of FRP grid is smooth, good gloss, high strength and a certain toughness. If the use of inferior resin will be completely the opposite of inferior resin turbidity, high viscosity, high heat release, high shrinkage, curing is relatively slow, poor compatibility, the production of FRP grid porous, easy to fracture, poor strength toughness is not good.

In the FRP grid can enhance the toughness of the grid is FRP fiber wire. High quality FRP fiber wire such as no alkali type FRP fiber wire strength is higher than steel wire has a certain toughness, chemical stability, good weather resistance, almost no water absorption fire does not burn, his high strength can also be used as a tire cord.

The filling material of FRP grid is calcium powder or aluminum powder, the high quality filling powder is fine and white, with flame retardancy, and the complete fusion with resin, the production of the board is beautiful color, good transparency and toughness. On the contrary, inferior filler powder is rough and dim, not flame retardant, the production of the board without gloss, more brittle without toughness.

2)Comparison of finished products.

High quality FRP grating products have no obvious cracks in the appearance, less pores, bright color and pure, good transparency, with a certain toughness and strength, good surface finish, long service life; And the appearance of inferior FRP grating products has cracks, more pores, color is not pure gloss is not enough. Its service life is also shorter.

Although fiberglass steel plate can not completely replace the steel plate, but fully make up for the steel plate can not meet the conditions or fields. Fully reduce the load of the steel grid non-capacity burden, but also for people to provide another solution to the problem. Its appearance has become a powerful complement to the steel grid.

3)Practice is the sole criterion for testing truth time is the fairest judge.

FRP gratings in actual use will be exposed in the process of his real strength, high-quality glass fiber reinforced plastic grille using derivatives slightly dim a few years later, the whole board is in good condition, no obvious damage, poor quality of glass fiber reinforced plastic grille, yield to the test of practice, use a few years later can appear the obvious damage, such as corrosion fracture porosity board is not so smooth, Serious color degradation, overall aging, generally FRP steel grille is to use 20 years, but two years later, inferior FRP grille will appear the whole aging phenomenon, so it brings huge losses to customers.

Conclusion

According to all description of frp gratings, we can get a general idea of all type we can choose when buy this products for project, after confirm the specification of grating, then choose a good supplier who can provide with a good quality with better price is the next step.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025