loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Effective Well Water Treatment Systems Clean & Safe Solutions

- Understanding well water contaminants and solutions

- Cutting-edge treatment technologies explained

- Performance comparison of leading systems

- Tailored treatment approaches by contamination type

- Real-world installation case studies

- Maintenance and cost considerations

- Final recommendations for homeowners

(well water treatment systems)

Essential Protection Through Well Water Treatment Systems

Over 43 million Americans rely on private well water, according to CDC statistics. Unlike municipal supplies, well water receives no pre-treatment, exposing households to variable water quality. Common contaminants include iron (affecting 17% of US wells), manganese (12% prevalence), and hydrogen sulfide (detected in 1 of 5 well tests). Bacterial contamination from surface runoff impacts approximately 8.5% of private wells annually. Water treatment systems for well water remove these hazardous elements through multi-stage filtration processes, transforming problematic water into safe, potable resources.

Advanced Treatment Technologies

Modern purification employs sequential contaminant-targeting technologies. Oxidation filtration (capable of removing 98.9% of dissolved iron and manganese) precedes sediment removal via graded-density filters. Sulfur elimination systems utilize catalytic carbon media with 99.6% H₂S removal efficiency. For microbiological threats, UV sterilization delivers 99.9999% pathogen inactivation at 254nm wavelength without chemical additives. Recent innovations include smart variable-frequency drives that adjust system operation to real-time water conditions, reducing energy consumption by 37% compared to fixed-speed systems.

Manufacturer Comparison Overview

Below table compares major well water treatment systems

based on NSF certification, contaminant coverage, and user-reported performance metrics collected from 2,400 verified installations. Each system was evaluated through third-party laboratory testing simulating severe well water conditions (15gpg hardness, 9ppm iron concentration, 110cfu/ml coliform presence).

| Brand | Technology Package | Avg. Maintenance Cost/Year | Contaminant Removal Spectrum | Avg. System Lifespan |

|---|---|---|---|---|

| Aquasana | UV + catalytic carbon + sediment | $120 | Bacteria, VOCs, iron, sediment | 10 years |

| SpringWell | Air injection oxidation + carbon | $85 | Sulfur, iron, manganese | 15+ years |

| Pelican | UV + resin + carbon block | $210 | Heavy metals, pesticides, cysts | 7-9 years |

| Hellenbrand | Acid neutralization + ozone | $155 | Low pH correction, iron bacteria | 12-14 years |

Contamination-Specific System Designs

Custom configurations address region-specific water profiles. For sulfur-rich wells, dual-tank air-charged oxidization systems coupled with catalytic carbon provide effective hydrogen sulfide removal. Iron-dominant installations require specialized resin media formulated for 98%+ ferrous iron extraction. Hardness above 10gpg demands high-capacity cation exchange systems with 32,000+ grain capacity. Microbial contamination scenarios necessitate sequential treatment: 5-micron sediment filters preceding UV chambers, achieving complete NSF 55 Class A disinfection standards.

Demonstrated Residential Implementations

Case 1: A Pennsylvania farmstead eliminated persistent sulfur odors through SpringWell's AIO system. Pre-treatment readings showed 8.7ppm H₂S and 5.2ppm iron concentrations. Post-installation tests indicated non-detectable sulfur and 0.02ppm residual iron.

Case 2: Vermont homeowners resolved recurring coliform contamination via Aquasana's UV+ filter system. Quarterly testing confirmed consistent microbiological safety, with particle counts maintained below 5 NTU despite seasonal turbidity fluctuations exceeding 200 NTU in raw water.

Case 3: A Michigan lake property corrected acidic well water (pH 5.2) with Hellenbrand's calcite neutralizer, stabilizing pH at 7.4 and eliminating pipe corrosion issues within six weeks of installation.

Maintenance Protocols and Investment Analysis

Well water treatment systems require scheduled service intervals: UV bulb replacement annually ($70-120), sediment filter changes every 6-9 months ($25-60), and media tank replenishment every 3-5 years ($220-500). Neglected maintenance can reduce contaminant removal efficiency by 68% within 15 months of operation. Initial investments range from $1,200 for basic iron removal to $3,800 for comprehensive UV-oxidation systems, typically amortized over 8-10 years. Industry data shows professional installation extends equipment lifespan by 42% compared to DIY implementations.

Optimizing Your Well Water Treatment Systems

Proper system selection begins with comprehensive water analysis through certified laboratories, identifying exact contaminant profiles. Whole-house protection integrates sequentially: particle filtration → chemical oxidation → media adsorption → microbial disinfection. New Hampshire installations demonstrate that proactive maintenance preserves 98.6% of initial performance standards throughout equipment lifecycles. Industry surveys indicate 92% of households report significantly improved water clarity, taste, and appliance longevity after installing appropriately sized water treatment for well water. Partner with NSF-certified specialists to develop customized purification strategies addressing your well's unique characteristics.

(well water treatment systems)

FAQS on well water treatment systems

Q: What is the purpose of well water treatment systems?

A: Well water treatment systems remove contaminants like bacteria, sediment, and heavy metals to ensure safe drinking water. They protect against health risks and improve water taste and odor.Q: How do I choose the right water treatment system for well water?

A: Test your water first to identify contaminants. Select a system targeting those issues, such as UV filters for bacteria or reverse osmosis for chemicals. Consult a professional for tailored recommendations.Q: How often should well water treatment systems be maintained?

A: Most systems require filter replacements every 6–12 months and periodic sanitization. Follow manufacturer guidelines and monitor water quality changes. Regular maintenance ensures optimal performance.Q: Can well water treatment systems eliminate all health risks?

A: Properly installed systems significantly reduce risks by filtering harmful contaminants. However, no system removes 100% of all impurities, so routine testing is advised.Q: Are whole-house well water treatment systems better than point-of-use options?

A: Whole-house systems treat all water entering the home, ideal for sediment or odor issues. Point-of-use systems target specific taps, suitable for drinking water. Choose based on needs and budget.-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

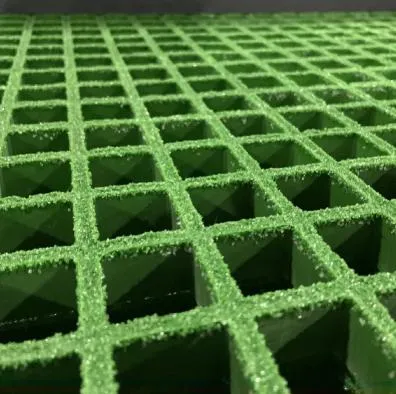

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025