loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

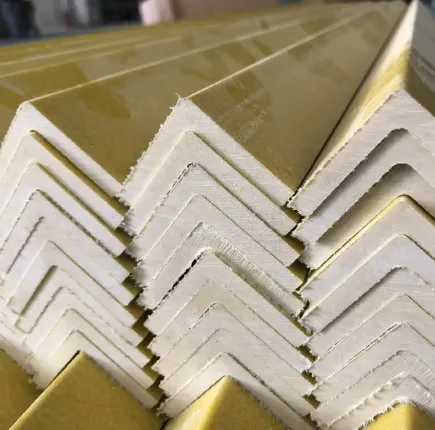

Versatility of FRP Profiles

In the world of advanced construction and industrial materials, FRP profiles (Fiberglass Reinforced Plastic profiles) have emerged as a revolutionary choice. Their exceptional strength-to-weight ratio, corrosion resistance, and design flexibility make them the preferred alternative to traditional materials like steel, aluminum, and wood.

Whether you’re designing a structural framework, constructing platforms, or reinforcing infrastructure, FRP profiles offer unmatched reliability and efficiency. Their lightweight nature and resilience ensure they perform effectively across diverse applications, from marine environments to industrial facilities.

Why FRP Pultruded Profiles Are a Game-Changer

For applications demanding precision and durability, FRP pultruded profiles stand out as the ultimate solution. These profiles are created through a specialized pultrusion process, where continuous fiberglass reinforcements are combined with resin and pulled through a heated die. This results in highly consistent, durable, and customizable profiles suitable for a range of industries.

One of the key benefits of FRP pultruded profiles is their ability to resist corrosion. Unlike metal profiles, which can degrade in harsh chemical or saline environments, FRP pultruded profiles maintain their structural integrity, making them ideal for use in chemical plants, wastewater facilities, and coastal areas.

In addition, their lightweight yet strong composition allows for easy transportation and installation, reducing labor costs and project timelines. Whether used in grating systems, handrails, or structural beams, FRP pultruded profiles deliver superior performance that stands the test of time.

Explore the Benefits of FRP Pultruded Sections

FRP pultruded sections are a specialized subset of FRP products that offer unparalleled design flexibility and strength. These sections include I-beams, channels, angles, and custom shapes, catering to a wide variety of structural needs.

The manufacturing process for FRP pultruded sections ensures consistent quality and performance, even under extreme conditions. Their non-conductive and non-magnetic properties make them particularly valuable in electrical and telecommunications applications. Additionally, their fire-retardant features provide an extra layer of safety, making them suitable for critical environments.

What sets FRP pultruded sections apart is their low maintenance requirements. Unlike traditional materials that may require regular painting or replacement due to rust or wear, FRP pultruded sections remain functional and visually appealing with minimal upkeep. This translates to significant cost savings over the lifecycle of a project.

Choosing the Right FRP Profiles for Your Project

When selecting FRP profiles for your project, it’s essential to consider factors such as load-bearing requirements, environmental conditions, and desired longevity. Whether you need FRP pultruded profiles for heavy-duty applications or FRP pultruded sections for specific structural configurations, consulting with experienced suppliers can ensure you find the right fit.

A reputable supplier will offer a wide range of FRP profiles and provide guidance on selecting the best products for your needs. Customization is also a key advantage of FRP materials, as they can be manufactured in various shapes, sizes, and finishes to meet unique specifications.

By choosing the right FRP profiles, you can enhance the safety, efficiency, and sustainability of your projects, ensuring they meet the highest standards of performance.

Why Now is the Time to Invest in FRP Pultruded Profiles and Sections

The growing demand for sustainable and cost-effective building materials has made FRP pultruded profiles and FRP pultruded sections a popular choice across industries. Advances in technology have further improved their strength, durability, and environmental performance, making them an investment in the future of construction and infrastructure.

With their lightweight nature, easy installation, and low maintenance requirements, FRP profiles offer long-term cost savings while delivering exceptional functionality. Industries ranging from transportation to energy production are increasingly adopting these materials to meet modern challenges and standards.

Investing in FRP pultruded profiles and FRP pultruded sections today means equipping your projects with a material that combines innovation, reliability, and sustainability. As the market for FRP products continues to grow, now is the perfect time to harness their benefits and revolutionize your operations.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025