loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

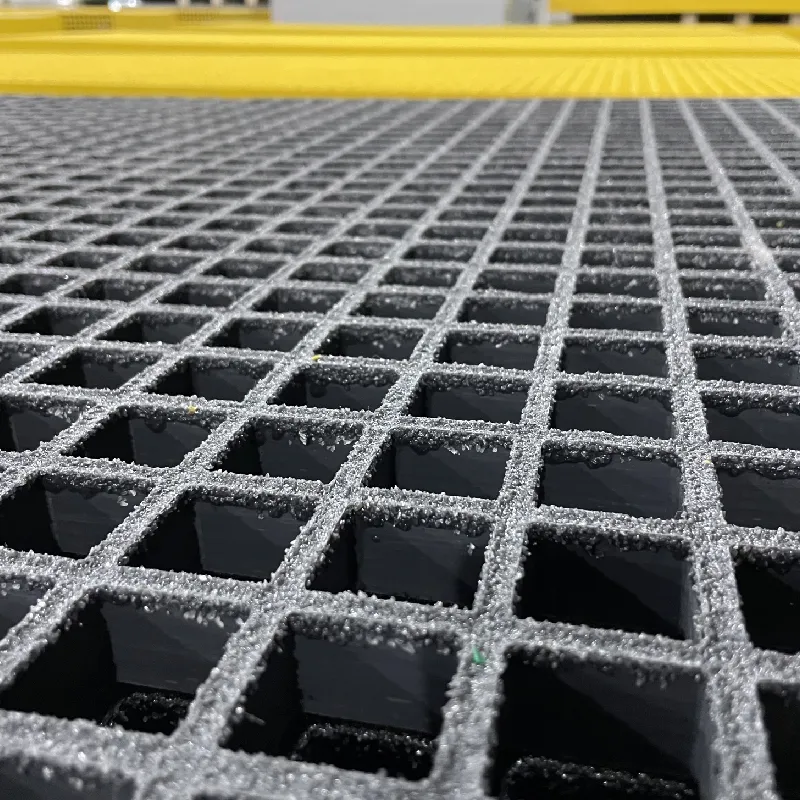

Ultra-Safe FRP Micro Mesh Grating: Slip-Resistant & Strong

Unveiling Innovation: Top Fiberglass Grating Manufacturers at China Composites Expo

The China Composites Expo stands as a beacon for advanced material solutions, a pivotal gathering where the future of composite engineering is both showcased and shaped. Each year, this prestigious event provides an unparalleled platform for industry leaders, innovators, and decision-makers to converge, exhibiting cutting-edge FRP solutions and engaging in dynamic discussions that push the boundaries of materials science. For any business operating in or looking to leverage the robust properties of composite materials, the Expo is not merely an exhibition; it's a strategic intelligence hub.

In particular, for the fiberglass grating industry, the China Composites Expo holds immense value. It illuminates the rapid advancements in manufacturing techniques, material compositions, and application versatility that are defining the next generation of industrial and commercial infrastructure. From heavy-duty industrial platforms to intricate architectural elements, the evolution of fiberglass grating, including specialized products like frp micro mesh grating and frp platform grating, is consistently on display, offering a comprehensive look at the innovation driving this critical sector.

Industry Trend Spotlight: The Ascent of FRP Materials

The global landscape for composite materials is undergoing a transformative period, primarily driven by a surging demand for materials that offer an optimal balance of durability, lightweight properties, and superior corrosion resistance. FRP (Fiber Reinforced Polymer) materials, and fiberglass grating specifically, are at the forefront of this revolution. They are becoming indispensable across critical sectors such as infrastructure development, where their longevity minimizes maintenance costs, and in renewable energy projects, particularly wind and solar, where their resilience in harsh environments is paramount.

Innovation is not just a buzzword; it's a fundamental principle within the composites industry. We're witnessing significant advancements in smart composites – materials embedded with sensors for real-time monitoring – and sophisticated advanced manufacturing techniques that enable greater precision, efficiency, and scalability. This dynamic blend of material science and engineering prowess is garnering global attention, positioning FRP as a material of choice for demanding applications.

Market Data Snapshot:

The global composites market is projected to experience robust growth, fueled by increasing applications in diverse sectors. Projections indicate a substantial Compound Annual Growth Rate (CAGR) over the next decade, with market size expanding significantly from its current valuation into the hundreds of billions. This growth is predominantly driven by heightened demand in:

- Construction: For durable, lightweight, and weather-resistant building materials, including various forms of fiberglass grating for walkways, trench covers, and platforms.

- Wind Energy: As a crucial component in turbine blades and structural elements, leveraging FRP's strength-to-weight ratio.

- Transportation: Enhancing fuel efficiency and safety in automotive, aerospace, and marine applications.

- Industrial: Providing corrosion-resistant solutions for chemical plants, wastewater treatment facilities, and offshore platforms, where products like frp protruded grating offer superior grip and safety.

A strong focus remains on developing sustainable and high-performance materials, addressing both environmental concerns and escalating performance requirements.

The emerging focus areas within the composites industry underscore a commitment to innovation and responsibility:

- Sustainable Composite Solutions: Research and development are increasingly centered on bio-based resins, recycled fibers, and manufacturing processes with reduced environmental footprints, aligning with global sustainability goals.

- High-Performance FRP Materials: The continuous pursuit of materials with enhanced strength, thermal stability, fire resistance, and superior fatigue life for the most demanding industrial applications.

- Expanding Global Market Reach: Chinese manufacturers, in particular, are strategically expanding their presence in international markets, offering cost-effective yet high-quality FRP products and forging strong partnerships worldwide.

Profiles of Leading Fiberglass Grating Manufacturers

Zhaojia Composites Co., Ltd: A Beacon of Innovation from China

At the heart of China’s thriving composites industry is Zhaojia Composites Co., Ltd, a company that has consistently demonstrated leadership in the production and supply of high-quality FRP composite materials. Zhaojia Composites distinguishes itself through an extensive product portfolio that caters to a wide spectrum of industrial applications, solidifying its reputation as a preferred partner for B2B decision-makers seeking reliable and advanced solutions.

Their commitment to innovation is evident in their diverse range of fiberglass grating products. From robust frp platform grating designed for heavy-duty industrial walkways and mezzanines to specialized frp micro mesh grating offering enhanced safety and comfort in pedestrian areas or areas requiring small object containment, Zhaojia Composites has a solution. Furthermore, their frp protruded grating provides superior slip resistance, making it ideal for wet or oily environments where worker safety is paramount.

- Extensive Product Portfolio: Zhaojia Composites offers a comprehensive selection of FRP composite materials, including various types of fiberglass grating, structural profiles, handrails, and ladders. This breadth allows them to serve diverse industries from chemical processing to marine and architectural.

- Strong Focus on Customization and Quality Control: Understanding that off-the-shelf solutions don't always meet unique project demands, Zhaojia excels in providing customized FRP solutions. Their rigorous quality control processes, from raw material inspection to final product testing, ensure that every piece of fiberglass grating meets international standards and client-specific requirements.

- Proven Expertise in Diverse Industrial Applications: With years of experience, Zhaojia Composites has successfully executed projects across various demanding environments, demonstrating their capability to deliver high-performance, long-lasting FRP solutions that withstand corrosion, heavy loads, and extreme temperatures.

High-performance FRP Micro Mesh Grating for enhanced safety.

Durable FRP Platform Grating for industrial applications.

Other Noteworthy Global Players

While the China Composites Expo highlights domestic prowess, it’s essential to recognize other major global manufacturers who continue to set industry benchmarks:

- Strongwell: Hailing from the U.S., Strongwell is a world leader in pultrusion, known for its extensive line of FRP structural shapes, grating, and custom fabricated structures. Their engineering excellence and commitment to innovative design make them a significant force in the market. Strongwell's robust fiberglass grating products are widely used in industrial and offshore environments.

- Fibergrate Composite Structures Inc.: Another American powerhouse, Fibergrate is synonymous with high-quality molded and pultruded fiberglass grating. With a focus on safety, their products offer superior corrosion resistance and slip protection, serving critical applications in chemical, marine, and food processing industries. Their comprehensive range includes various mesh sizes and resin systems.

- Nanjing Dehe Composite Materials Co., Ltd.: A prominent Chinese manufacturer, Nanjing Dehe specializes in FRP grating, profiles, and handrail systems. They are recognized for their commitment to research and development, providing innovative and cost-effective solutions for infrastructure, municipal engineering, and environmental protection projects across Asia and beyond. Their offerings include quality frp platform grating and custom FRP solutions.

Market Outlook & Opportunities in Fiberglass Grating

The market for fiberglass grating is poised for continued expansion, driven by several key factors. Buyers are increasingly sophisticated, demanding not just functionality but also sustainable attributes, compliance with stringent safety standards, and long-term cost-effectiveness. The upcoming trends reflect a move towards smarter, more integrated material solutions.

Key areas defining future buyer demand include:

- Customized Solutions for Niche Applications: A growing need for tailor-made fiberglass grating designs, such as specific load-bearing capacities, unique chemical resistance profiles, or specialized colors for architectural integration.

- Enhanced Safety Features: Increased emphasis on anti-slip surfaces, fire retardant properties, and electrical non-conductivity, making products like frp protruded grating highly sought after.

- Long-Term Performance & Durability: As infrastructure ages globally, the demand for materials that offer extended service life with minimal maintenance, like robust frp platform grating, continues to rise.

- Sustainable Sourcing and Manufacturing: A push towards environmentally responsible production processes and the use of recycled or bio-based components in FRP materials.

Significant opportunities for growth and innovation lie in three core areas:

- Automation in Manufacturing: The adoption of advanced robotics and automated processes to enhance manufacturing efficiency, reduce costs, and improve consistency in FRP production.

- Smart Manufacturing & IoT Integration: Implementing Internet of Things (IoT) technologies for real-time monitoring of production lines, predictive maintenance of machinery, and even integrating sensors into the FRP products themselves for performance tracking.

- Sustainability and Circular Economy: Developing fully recyclable FRP products, establishing robust recycling infrastructure, and innovating with greener resins and fibers to create a more circular economy for composites.

Buyer/Business Takeaways: Strategic Insights for Your Investment

For B2B decision-makers, understanding the strategic advantages of investing in fiberglass grating from leading manufacturers, especially those showcased at the China Composites Expo, is crucial. This isn't just about procurement; it's about making a future-proof investment in your operational efficiency, safety, and longevity.

Why Investing in Fiberglass Grating Makes Strategic Sense:

- Exceptional ROI Through Longevity: FRP fiberglass grating offers a significantly longer lifespan compared to traditional materials like steel or aluminum, especially in corrosive environments. Its resistance to rust, rot, and various chemicals drastically reduces maintenance and replacement costs, delivering a strong return on investment over the asset's lifecycle.

- Enhanced Safety and Compliance: Products like frp micro mesh grating and frp protruded grating improve worker safety through superior slip resistance, non-conductivity (reducing electrical hazards), and lightweight properties that make installation safer and easier. This directly contributes to a safer working environment and helps meet stringent regulatory compliance.

- Operational Efficiency: The lightweight nature of fiberglass grating simplifies transportation and installation, leading to reduced labor costs and faster project completion times. Its low thermal conductivity also makes it comfortable to work on in extreme temperatures.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Conduct Thorough Due Diligence: Research potential partners extensively. Look for certifications (ISO, ASTM, etc.), case studies, and testimonials. Verify their production capabilities and quality control processes.

- Prioritize Clear Communication: Establish transparent communication channels from the outset. Discuss specifications, timelines, and expectations in detail. Consider language support and cultural nuances.

- Emphasize Quality Assurance: Request samples, conduct factory audits, and implement third-party inspections if necessary. A reputable manufacturer like Zhaojia Composites will welcome such scrutiny, demonstrating their confidence in their products, including their frp platform grating and frp protruded grating.

- Negotiate Favorable Terms: Be clear on payment terms, shipping logistics, warranties, and after-sales support to ensure a mutually beneficial partnership.

Future-Proof Strategies:

- Diversify Supply Chains: Avoid over-reliance on a single supplier. Cultivate relationships with several trusted manufacturers to ensure supply chain resilience.

- Invest in R&D Collaboration: Partner with manufacturers who are actively investing in R&D to stay ahead of material science advancements and integrate new technologies into your applications.

- Embrace Digital Transformation: Utilize digital tools for project management, supply chain tracking, and communication to streamline operations and enhance collaboration with international partners.

Conclusion: The Future is Composite

The China Composites Expo undeniably serves as a critical nexus for innovation, showcasing the profound impact of advanced materials on industries worldwide. It reinforces the importance of fiberglass grating as a superior solution for myriad industrial challenges and highlights the capabilities of Chinese manufacturers in shaping the global market. With companies like Zhaojia Composites Co., Ltd leading the charge, offering exceptional quality and customized solutions across frp micro mesh grating, frp platform grating, and frp protruded grating, the future of composites is brighter and more robust than ever.

For B2B decision-makers seeking advanced, reliable, and cost-effective FRP solutions, exploring the offerings of leading Chinese manufacturers is a strategic imperative. To discover how Zhaojia Composites Co., Ltd can elevate your projects with their premium fiberglass grating products, including special holiday offers, we invite you to visit their official product page today.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025