loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Top FRP Grating Suppliers for Durable Micro Mesh Grating Solutions

About Zhaojia Composites Co., Ltd

Zhaojia Composites Co., Ltd (https://www.zjcomposites.com) stands out as a global leader among frp grating suppliers. With years of professional expertise, we’re recognized for advanced manufacturing, innovation and strict quality control in fiberglass reinforced plastic (FRP) gratings.

- Phone: +86 15031801825 / +86 15097380338

- Email: admin@zjcomposites.com

- Address: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

FRP Grating Industry Trends in 2024

As the demand for lightweight, corrosion-resistant, and high-strength materials rises, frp grating suppliers are experiencing significant growth. Industry applications are expanding from industrial plants, chemical facilities, offshore platforms, to public infrastructure and even architectural design. In particular, frp micro mesh grating offers enhanced anti-slip and security for walkways, ramps, stair treads, machine platforms, and trench covers.

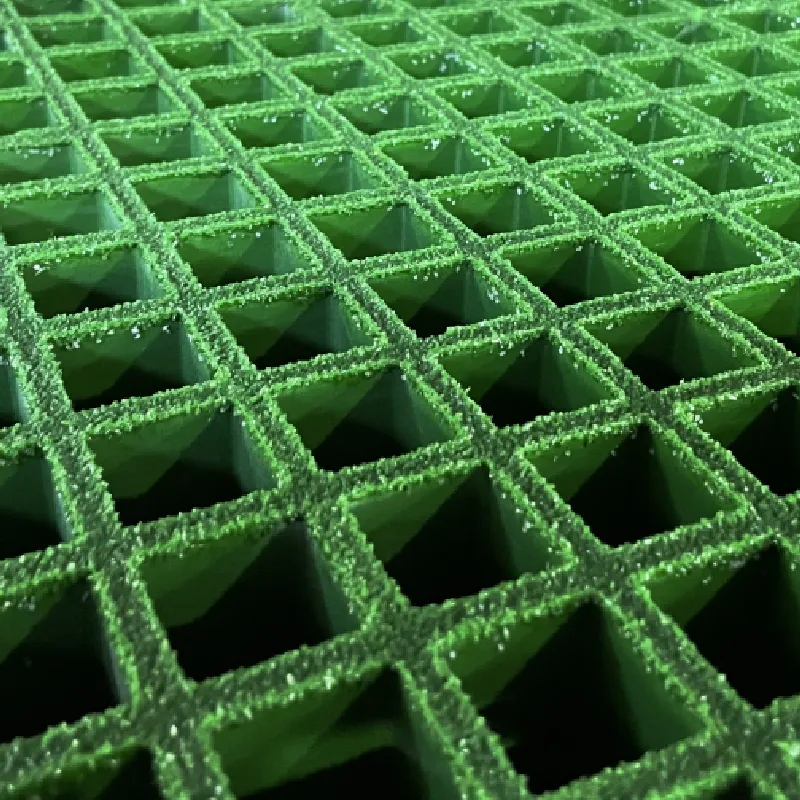

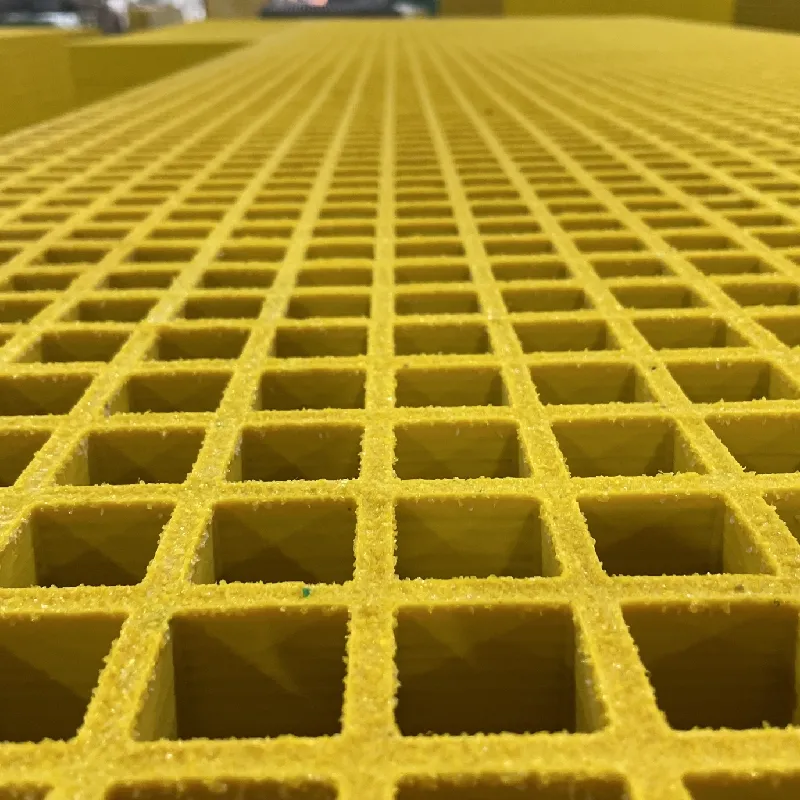

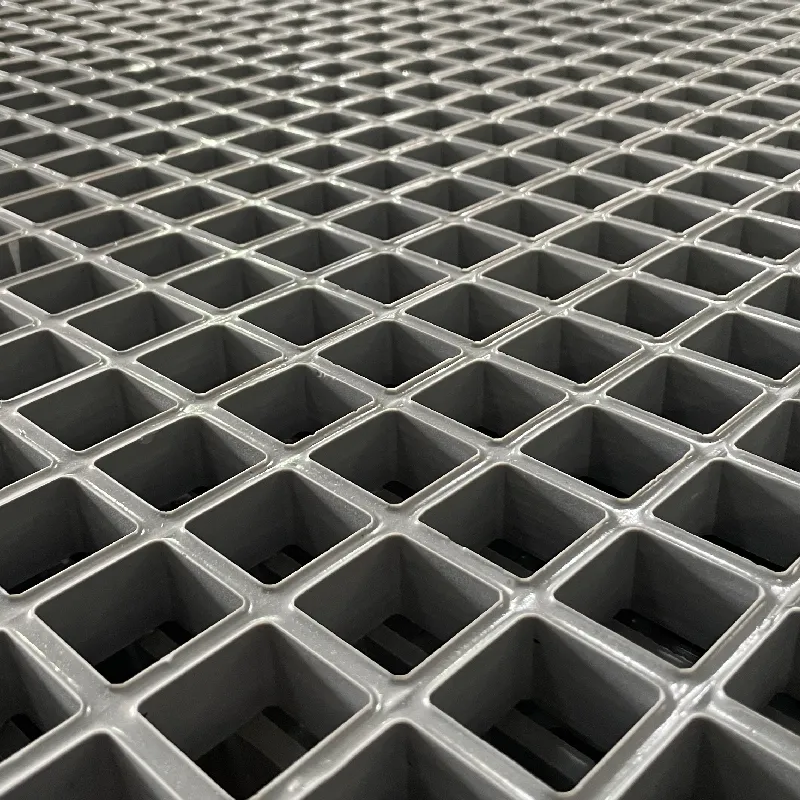

Product Spotlight: Anti Slip & Factory Outlet Standard Mesh FRP/GRP Grating

Zhaojia Composites Co., Ltd presents the Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating — the next generation of reinforced flooring grating offering superior value among frp grating suppliers.

Product Introduction:

FRP/GRP/Fiberglass (Fiberglass Reinforced Plastic) grating is the clear choice over steel or aluminum grating for its lightweight, corrosion resistance, UV stability, and easy installation. There’s no need for special tools or hot works during mounting, making it ideal for fast deployment and long-term durability in harsh environments.

Comparative Table: Top FRP Grating Suppliers & Key Parameters

| Supplier | Location | Main Product Types | Mesh Size Options | Anti-slip Feature | Certifications | Lead Time |

|---|---|---|---|---|---|---|

| Zhaojia Composites | China | FRP/GRP Grating, Micro Mesh, Pultruded Grating | 25x25, 38x38, Micro mesh 12x12mm | Yes (integral grit surface) | ISO9001, SGS | 7-20 days |

| Fibergrate | USA | Molded & Pultruded Grating | 38x38, Micro mesh | Optional | ISO9001 | 15-30 days |

| Techno-Composite | Europe | Molded FRP, Walkway Panels | Varied | Yes | REACH | 15-25 days |

| Ferrotech | India | FRP Gratings, Covers | Standard & micro mesh | Optional | ISO, SGS | 10-25 days |

Technical Specification Trends of FRP Grating Suppliers

FRP Micro Mesh Grating: What Sets It Apart?

FRP micro mesh grating is tailored for applications requiring minimal object fall-through, enhanced safety, and extra anti-skid performance — making it ideal for public walkways, offshore platforms, and food processing environments. Its tighter mesh size (commonly 12x12mm, 8x8mm) is preferred where high-heeled shoes, roller carts, or tool droppage might otherwise pose risks.

Key Technologies and Performance Comparison

Main Technical Indicators - Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating

| Parameter | Specification |

|---|---|

| Resin Type | Orthophthalic / Isophthalic / Vinyl Ester / Phenolic |

| Load Bearing | Up to 29 kN/m² (Uniform Load) |

| Surface | Integral Grit (Anti-slip) |

| Mesh Size | Standard 38x38mm / Micro Mesh 12x12mm |

| Thickness | 20–50mm (optional: custom sizes) |

| Fire Resistance | ASTM E84 Class 1 / EN13501-1 |

| UV Resistance | >14 years (outdoor exposure) |

| Operating Temperature | -40℃ ~ 120℃ |

| Certifications | ISO9001, SGS, ABS, DNV |

Application Scenarios for FRP Grating

FRP grating suppliers provide solutions tailored to diverse industries. The combination of micro mesh design, anti-slip surface, and high chemical resistance makes FRP gratings suitable for:

- Industrial Facilities: Walkways, platforms, trench covers, stairs, cable trays

- Marine & Offshore: Helidecks, rigs, Jetties, boat ramps

- Public Infrastructure: Drain covers, bridges, parks flooring, municipal walkways

- Food Processing & Beverages: Hygienic platforms, washing bays

- Chemical Plants: Battery rooms, pickling areas, storage zones

- Architecture: Facade sunshades, ventilation grills, fence panels

- Environmental: Wastewater treatment, desalination plants

Professional FAQ: Key FRP Grating Terms Explained

Q1: What raw materials are most commonly used by leading frp grating suppliers?

A: Premium frp grating suppliers use fiberglass roving (E-glass or C-glass) combined with high-grade resins: Orthophthalic, Isophthalic, Vinyl Ester, and for fire-critical/chemical zones, Phenolic resin. These ensure mechanical strength, chemical resistance, and longevity. (CompositesWorld)

Q2: What are the main mesh sizes for FRP micro mesh grating?

A: Standard meshes are 38x38mm or 25x25mm. FRP micro mesh grating usually refers to meshes smaller than 13x13mm (commonly 12x12mm or 8x8mm). The finer aperture limits object drop and increases traversing safety—recommended for public buildings and food facilities.

Q3: How are anti-slip properties achieved?

A: Anti-slip performance is imparted by embedding quartz sand particles (grit) onto the top resin layer while curing. Some frp grating suppliers also use a convex “meniscus” finish for additional grip. See details: Corrosionpedia

Q4: Which international standards govern FRP grating performance?

A: ASTM F3059 (USA), EN 13706 (EU), AS 1657 (Australia), and ISO 9001 certification are key. Fire & smoke performance is benchmarked by ASTM E84 (US) or EN 13501-1 (EU).

Q5: What are the typical load ratings and thickness selections?

A: Load rating varies with thickness and mesh. For 38mm thick standard mesh, uniform distributed load reaches 22–29 kN/m²; for micro mesh, 15–20 kN/m². Thinner panels (20–30mm) are suited for pedestrian or light-duty traffic.

Q6: How should FRP grating be installed, and are special tools needed?

A: FRP gratings can be field cut using carbide saws or diamond wheels; no welding or “hot works” are required. Installation is via stainless steel clips and bolts. Detailed guides are available from leading frp grating suppliers here: Installation Instructions

Q7: What factors should be considered when selecting frp micro mesh grating for corrosive or outdoor environments?

A: Consider resin type (vinyl ester for heavy chemicals), UV inhibitors, grit profile, and certification. For chloride exposure (marine), isophthalic or vinyl ester is best. For sunlight, ensure UV stabilizers are present.

Why Choose Zhaojia Composites As Your FRP Grating Suppliers?

- Factory Outlet Pricing: Competitive cost advantage from direct production

- Customization: Mesh size, thickness, color, resin type — all tailored to your application

- Swift Global Delivery and comprehensive after-sales support

- ISO, SGS, ABS, DNV Certified: Product traceability and third-party quality assurance

- Proven Export Track Record: Projects in 60+ countries

Further Industry Insights and Authoritative References

- Selection and Application of FRP Gratings - Composite Structures Journal (Read the Paper)

- Industry Experience Exchange - GRP Grating Discussion Forum (ENG-TIPS Forum)

- FRP Grating Market Trends & Projections - CompositesWorld (Market Trends)

- Material Advantages Explained - Fibre Reinforced Polymer Wiki (Wikipedia)

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025