loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Top FRP Grating Suppliers for Durable FRP Micro Mesh Grating Solutions

Explore comprehensive insights and trends in the Fiber Reinforced Plastic (FRP) grating industry. From technology and standards to applications and supplier benchmarking, this guide will help you invest confidently in high-performance FRP grating suppliers and advanced FRP micro mesh grating solutions.

View Product Details

Industry Trends & Market Overview: FRP Grating Suppliers in 2024

According to MarketsandMarkets Research, the global FRP grating market is projected to surpass USD 800 million by 2027 at an impressive CAGR of 4.7%. Key demand is driven by corrosion resistance, lightweight, and safety advantages across petrochemical, water treatment, offshore marine, metallurgy, and commercial flooring domains. Leading frp grating suppliers emphasize compliance with international standards such as ISO 9001, ANSI/NAAMM FG 1-2016, and DIN EN 13706 for product quality assurance.

Technical Insights: Key Specifications of FRP Grating Suppliers

FRP Grating Supplier Technical Comparison Table (2024)

| Supplier | Main Material | Mesh Type | Resin Options | Open Area (%) | Compressive Strength (MPa) | Certifications | Typical Warranty |

|---|---|---|---|---|---|---|---|

| ZHPC Composites | E-glass, Polyester/VE resin | Standard, Micro Mesh | Isophthalic, Orthophthalic, Vinyl Ester | 68 | >200 | ISO 9001, SGS, ASTM E84 | 10 years |

| Fibergrate | E-glass, Isophthalic resin | Standard, Mini-Mesh | Isophthalic, Phenolic | 70 | ≈225 | UL, FDA, ISO 9001 | 15 years |

| Bedford Reinforced Plastics | E-glass, Vinyl Ester | Standard, Micro Mesh | Vinyl Ester, Polyester | 69 | ~185 | ANSI, ISO, DNV-GL | 12 years |

| AGC FRP | S-glass, Polyester | Standard | Polyester | 67 | 180 | ISO 9001, DNV, SGS | 8 years |

| Shanghai Ruifiber | E-glass, Polyester | Mini, Micro Mesh | Isophthalic, VE | 66 | 190 | UL 94, ISO, SGS | 10 years |

Manufacturing Process of FRP Grating Suppliers: Step-by-Step Flow

Resin blending

Pultrusion

Material & Engineering Advantages of FRP Grating Suppliers

- Corrosion Resistance: Outperforms steel, resists acids/alkalis/salt spray. Maintains structure even after 5000h ASTM B117 Salt Fog Test.

- High Load-bearing: Typical compressive strengths 180–225MPa, bending strength ≥230MPa, suitable for heavy traffic areas.

- Dielectric Performance: Excellent insulation, leakage resistance above 1012Ω.

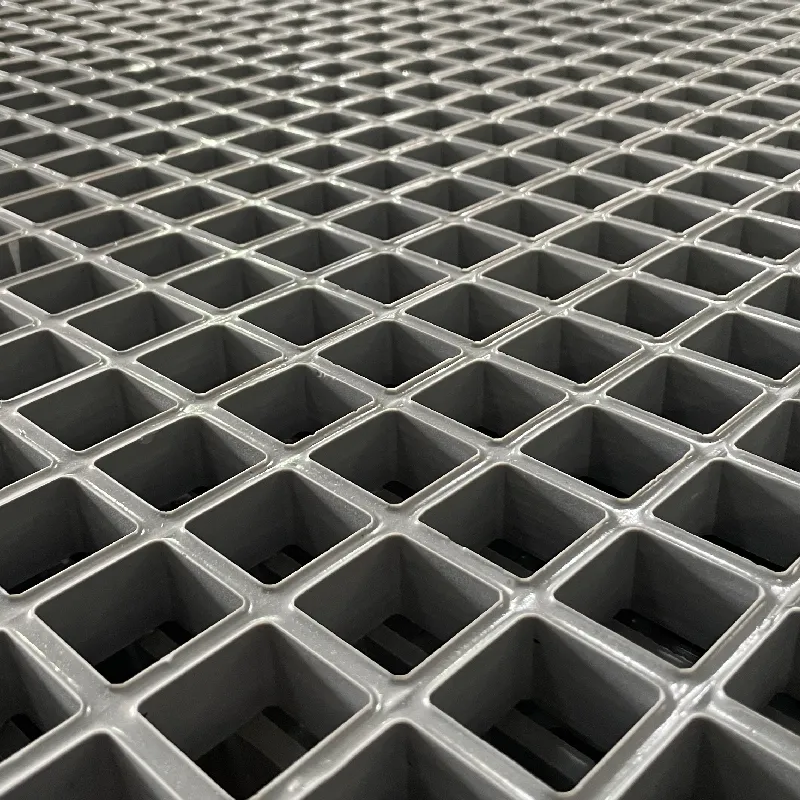

- Anti-slip & Surface Variants: Grit surface, concave, and chequered surfaces, R12-R13 slip rating compliant to OSHA.

- UV & Fire Resistant: Fire retardancy (ASTM E84, Class 1), UV additives for 10+ year color fastness.

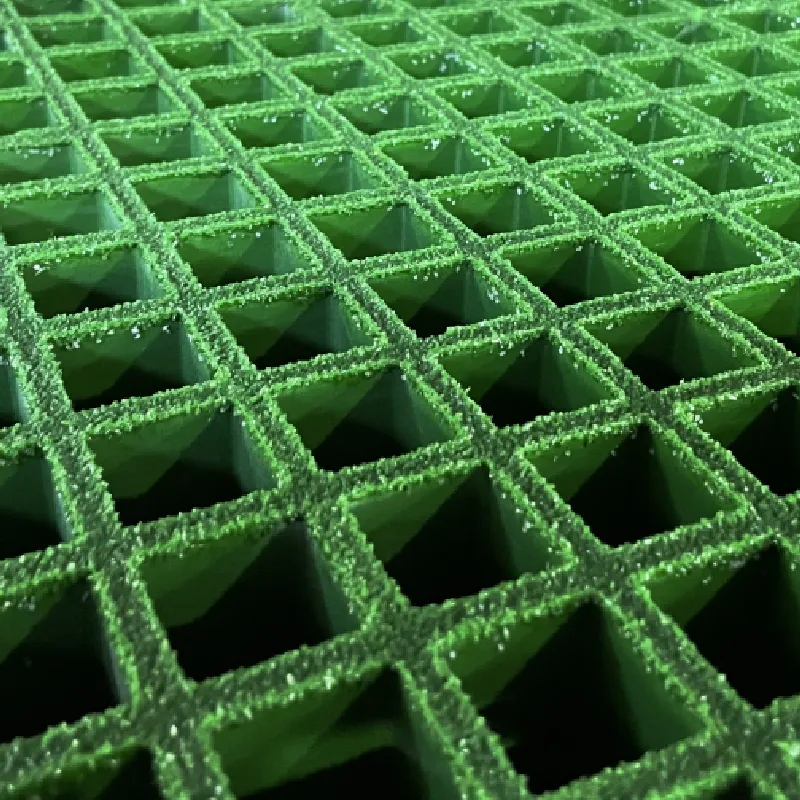

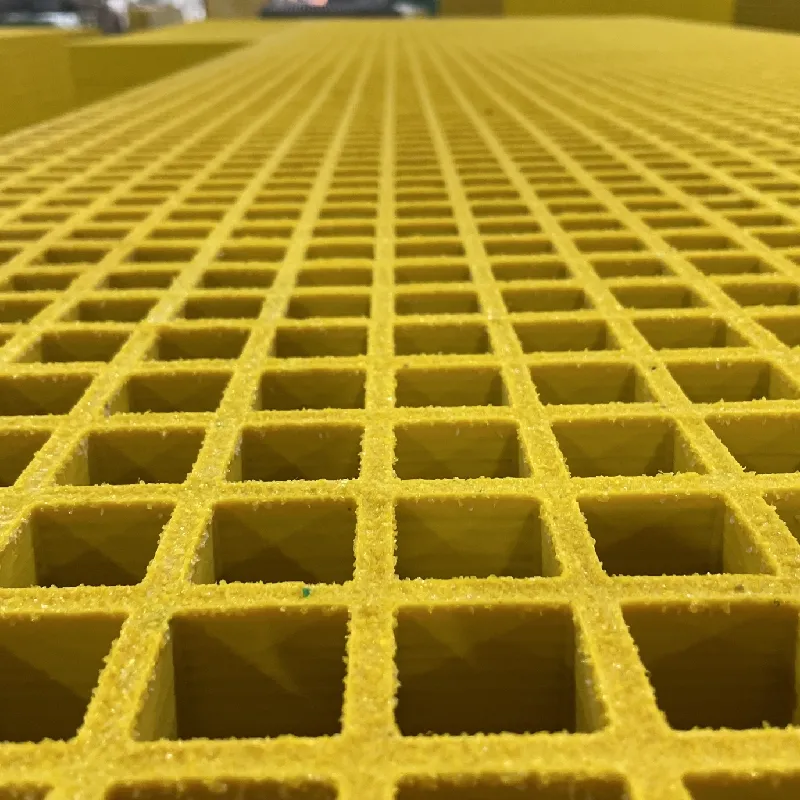

- Custom Colors & Micro Meshes: Customization to enhance aesthetics and prevent small object drop-through.

- Lightweight & Easy Installation: Weighs 80% less than steel grating, installation efficiency up by 30-50%.

FRP Micro Mesh Grating: Special Features

- Mesh Size: Typically 12.7 x 12.7mm (1/2" x 1/2") prevents tools/falling objects, complies with OSHA and BS 4592 safety.

- Applications: Cleanroom walkways, machine guarding, food/beverage production (FDA compliant), wastewater plants, transformer/fire-risk zones.

- Unrivaled Slip-resistance: Up to 1.0 coefficient with quartz grit finish.

- Customization: Panel color, resin type, and fire-retardant additive options.

Product Specifications: Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating

| Parameter | Value | Standard |

|---|---|---|

| Mesh Size (mm/inch) | 38 x 38 (1.5" x 1.5") | ANSI/NAAMM FG 1-2016 |

| Panel Thickness (mm) | 25 / 38 / 50 | ISO 14122, DIN 24537 |

| Resin Options | Isophthalic, Orthophthalic, Vinyl Ester | ASTM D256, ISO 9001 |

| Fire Retardance | ASTM E84 Class 1 | ASTM E84 |

| UV Resistance | >10 years (5000h, ASTM G154) | ASTM G154 |

| Max Panel Size (mm) | 1220 x 3660 | ISO 9001 |

| Bearing Bar Height (mm) | 25 / 30 / 38 / 50 | ISO, ANSI |

| Slip Resistance | R12-R13, Grit surface | DIN 51130 |

Product Testing & Certification

All product batches by top frp grating suppliers are tested per ISO 9001:2015 and third-party SGS, with tensile, bending, and fire tests conducted. Each batch receives a unique test reference for traceability.

Application Scenarios & Case Studies

- Offshore Oil Platforms: Offers outstanding corrosion resistance to seawater spray, ensuring walkways remain safe and maintenance-free (tested 12 years at Bohai Oilfield, PRC; delamination

- Municipal Wastewater Plants: Grit antiskid finish and chemical inertness, reducing cleaning frequency by 35% (compared to galvanized steel grating) and prolonged service life.

- Power Substations: Micro mesh grating as personnel walkway and shielding, eliminating electric shock risks (

- Food/Pharma Factories: FDA-compliant, anti-bacterial surface, fast cleaning, does not rust or de-colorate.

- Metallurgy: Tolerates acid/alkali wash down, anti-abrasion 9H (ASTM D3363), used at leading Asia steel mills since 2010.

Real Project Feedback Examples

- Client from Total Oil (Middle East): "Installed 2021, zero surface delamination, excellent anti-slip during storms – outperforming all steel equivalents."

- Chinese Municipal Water Bureau: "Inspection walkways still intact after 8 rainy seasons, no safety incidents, no rust—excellent long-term ROI."

- Chilean Copper Plant: "Choosing premium frp grating suppliers saved on annual maintenance; color, surface finish still as new after 5 years."

Customization, Delivery, and After-Sales: What Leading FRP Grating Suppliers Provide

- Design Support: Engineering diagrams, onsite dimensioning, professional load analysis per ANSI/NAAMM and DIN standards.

- Color & Resin Customization: Any RAL color, isophthalic/polyester/vinyl ester/phenolic for specific industrial resistance.

- CNC Cut-To-Size: Panels pre-trimmed to fit irregular installations, edge banded, fixings supplied.

- Delivery Commitment: Standard sizes: ship in 7 working days; bespoke cut/panel: 12-15 days (fast-tracked for urgent orders).

- Warranty: 10–15 years panel replacement against corrosion/structural failure (see certificate upon delivery).

- Compliance: 100% factory-tested, reports issued with each batch (SGS/UL/ISO on request).

- Global Service: Exported to 60+ countries, partnerships with Siemens, PetroChina, ThaiBev, MTR Hong Kong.

FAQ — Technical FAQ on FRP Grating Suppliers Products

Why Choose ZHPC Composites as Your FRP Grating Suppliers?

- Mix of 20+ years manufacturing, ISO-compliant QA systems, and global engineering presence (About ZHPC).

- Top supplier to Fortune 500 industrial clusters and international EPCs.

- Dedicated R&D center, continuous new product development—winners of 3 industry excellence awards.

- 24/7 support, 1-day product technical answers for professional design teams.

Citations & Further Reading

- MarketsandMarkets FRP Grating Industry Analysis – Link

- American Composites Manufacturers Association — Technical Guidance: Link

- OSHA Floor Safety Standards: Link

- ASHRAE Industry Forum: “FRP Grating Trends in Petrochemical Facilities” www.ashrae.org

- \[Forum\] Fiberglass Market Updates: Eng-Tips Composite Forums

- Composite Structures (Elsevier) – Academic Journal: Read Papers

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025