loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

tata frp vessel

Understanding the Significance of TATA FRP Vessels in Modern Engineering

In recent years, the engineering and manufacturing industries have witnessed a significant shift towards the utilization of composite materials due to their unique properties and advantages. Among these advancements, TATA FRP vessels stand out as a remarkable innovation. FRP, or Fiber Reinforced Polymer, is a composite material made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This article delves into the importance of TATA FRP vessels, exploring their composition, applications, benefits, and the future of this technology.

Composition and Properties of TATA FRP Vessels

TATA FRP vessels are constructed using a combination of polyester or vinyl ester resin and reinforcing fibers, primarily glass fibers. This fusion results in a material that exhibits high strength-to-weight ratios, excellent durability, and resistance to corrosive environments. One of the key properties of FRP is its lightweight nature, which makes handling and installation significantly easier compared to traditional materials like steel or concrete.

Moreover, TATA FRP vessels possess superior resistance to chemicals and environmental degradation. This makes them particularly suitable for industries that handle aggressive substances, such as the chemical processing and pharmaceutical sectors. The versatility of FRP allows for the creation of vessels in various shapes and sizes, catering to specific industry needs without compromising integrity and safety.

Applications of TATA FRP Vessels

The applications of TATA FRP vessels are extensive and varied. One of the most notable uses is in water treatment facilities, where these vessels store and transport chemicals and treated water. Their resistance to corrosion makes them ideal for environments that may degrade traditional storage solutions.

In the chemical industry, TATA FRP vessels are used to store and process aggressive chemicals safely. They prevent leaks and contamination while ensuring regulatory compliance. Their lightweight nature reduces transportation costs, making them an attractive alternative for manufacturers and suppliers.

Additionally, FRP vessels are gaining traction in industries such as food processing, pharmaceuticals, and wastewater treatment. In the food industry, their non-porous surface prevents bacterial growth, ensuring food safety and hygiene standards are upheld. In pharmaceuticals, TATA FRP vessels provide reliable storage solutions that adhere to stringent quality standards.

tata frp vessel

Benefits of TATA FRP Vessels

The advantages of using TATA FRP vessels are manifold. Firstly, their lightweight nature significantly reduces installation and transportation costs. Traditional vessels made from steel or concrete can be cumbersome and require heavy machinery for installation, while FRP vessels can often be installed without specialized equipment.

Secondly, the longevity and durability of FRP vessels lead to reduced maintenance costs over time. The inherent resistance to corrosion minimizes the need for regular upkeep, allowing companies to allocate resources more efficiently.

Environmental considerations also highlight the significance of TATA FRP vessels. Their ability to reduce the environmental impact of leaks and spills is crucial in today’s eco-conscious world. Moreover, as industries shift towards sustainability, the recyclability of FRP materials becomes an essential factor, contributing to a circular economy.

The Future of TATA FRP Vessels

Looking forward, the prospects for TATA FRP vessels appear promising. As technology advances, new formulations and manufacturing techniques are expected to enhance the properties of FRP materials further. Furthermore, increased awareness of environmental issues will likely drive demand for sustainable and efficient materials in various industries.

Research and development in composite materials may also lead to innovations that expand the applications of FRP vessels. The potential for integrating smart technologies, such as sensors for real-time monitoring of vessel integrity, could revolutionize how industries manage storage and transportation of hazardous materials.

Conclusion

TATA FRP vessels represent a significant advancement in engineering and manufacturing, offering an array of benefits across multiple industries. Their unique properties, coupled with their versatility and environmental advantages, position them as a preferred choice in an ever-evolving industrial landscape. As we continue to innovate and prioritize sustainability, TATA FRP vessels will undoubtedly play a crucial role in shaping the future of engineering solutions.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

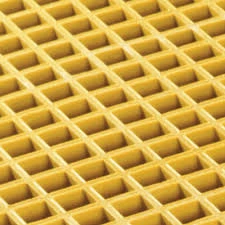

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025