loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of Structural FRP in Modern Engineering Solutions

Understanding Structural FRP A Revolutionary Material in Construction

In the ever-evolving world of construction and engineering, the search for innovative materials that enhance durability, reduce weight, and provide greater flexibility is paramount. One such advancement is Fiber-Reinforced Polymer (FRP), a composite material that has gained immense popularity in structural applications. This article delves into the characteristics, advantages, applications, and future prospects of structural FRP.

What is Structural FRP?

Fiber-Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The fibers provide strength and rigidity, while the polymer matrix offers environmental resistance and flexibility. Together, these components create a material that excels in various structural applications, from bridges and buildings to automotive and aerospace components.

Characteristics of Structural FRP

One of the key features of FRP is its lightweight nature, which allows for easier handling and installation compared to traditional materials like steel and concrete. This weight reduction also leads to lower transportation costs and potential savings in foundation requirements, as lighter structures exert less load on support systems.

In addition to being lightweight, structural FRP boasts impressive strength-to-weight ratios. Carbon fiber-reinforced polymers, for instance, are known for their exceptional tensile strength, making them suitable for high-stress applications. Additionally, FRP is inherently resistant to corrosion, making it an ideal choice for projects in harsh environments, such as coastal areas or chemical processing plants.

Another significant property of structural FRP is its versatility. It can be molded into various shapes and sizes, allowing architects and engineers to push the boundaries of design and aesthetics. Furthermore, FRP can be engineered to meet specific performance criteria, enhancing its suitability for diverse applications.

Advantages of Structural FRP

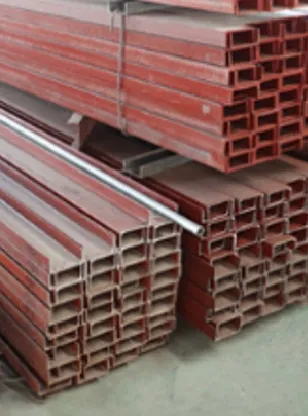

structural frp

The advantages of using structural FRP in construction are numerous. Firstly, the corrosion resistance of FRP reduces maintenance costs and prolongs the lifespan of structures. Unlike steel, which can degrade over time due to rust, FRP maintains its integrity even in challenging environments.

Secondly, the lightweight property of FRP can lead to reduced construction costs. Lighter materials require less support, allowing for slimmer, more cost-effective structural designs. This can also result in faster construction times, as heavier equipment is often unnecessary.

Moreover, FRP offers excellent energy efficiency. Structures made from FRP can contribute to sustainability goals by reducing material waste and energy consumption during both manufacturing and construction processes.

Applications of Structural FRP

The applications of structural FRP are vast and varied. In the construction sector, FRP is utilized in reinforcing concrete structures, creating bridge components, and even constructing entire buildings. Its resistance to environmental factors makes it ideal for use in wastewater treatment facilities and chemical plants.

Beyond construction, FRP is making significant strides in the automotive and aerospace industries. Lightweight FRP components can enhance fuel efficiency and improve performance in vehicles and aircraft. Additionally, FRP is being explored for use in renewable energy sectors, such as wind turbine blades, where its strength-to-weight ratio is particularly advantageous.

Future Prospects of Structural FRP

As technology advances and the demand for sustainable construction practices rises, the future of structural FRP looks promising. Ongoing research into enhancing the properties of FRP and reducing production costs indicates that its use will become even more widespread. Furthermore, the integration of smart technologies with FRP materials could lead to the development of self-sensing and reactive structures, enhancing safety and performance.

In conclusion, structural FRP represents a significant leap forward in construction materials, offering numerous benefits from weight reduction to corrosion resistance. Its applications are expanding across various sectors, showcasing its versatility and strength. As industries continue to seek sustainable and efficient solutions, FRP is poised to play a crucial role in shaping the future of construction and structural engineering. With continued innovation, the potential for FRP is boundless, paving the way for smarter, more resilient structures in the years to come.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025