loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Understanding Steel Channel Sizes and Their Applications in Construction Projects

Understanding Steel CHS Sizes An Overview

When it comes to construction and structural engineering, the choice of materials plays a pivotal role in determining the strength, durability, and efficiency of any project. Among the various materials available, steel stands out due to its remarkable properties, such as high tensile strength, ductility, and resistance to environmental degradation. One of the most commonly used forms of steel in construction is the Circular Hollow Section (CHS). This article delves into the various sizes and applications of steel CHS, providing insights for engineers, architects, and construction professionals.

What is Circular Hollow Section (CHS)?

A Circular Hollow Section (CHS) refers to a type of steel section that has a tubular shape, making it ideal for various structural applications. CHS is commonly used in beams, columns, and trusses, offering a balance between strength and weight. The unique round shape allows for uniform distribution of stress across its surface, which enhances its load-bearing capacity. Additionally, CHS is less prone to buckling compared to other cross-sectional shapes, such as rectangular or square sections.

Sizes of Steel CHS

Steel CHS is available in various sizes, identified by their diameter and wall thickness. The diameters typically range from small (around 20 mm) to large (up to 600 mm or more), allowing for flexibility in design and application. Wall thickness can vary as well, commonly falling within the range of 2 mm to 20 mm. The specific sizes are often designated by industry standards, ensuring consistent quality and performance.

In many regions, the size specifications are based on the guidelines set forth by organizations such as the American Institute of Steel Construction (AISC) or the British Standards (BS). This means that when specifying CHS for a project, it is crucial to refer to local codes and standards to ensure compliance and optimal performance.

Applications of Steel CHS

Steel CHS is utilized in a wide range of applications due to its versatile properties

. Here are some common uses1. Structural Frameworks CHS is frequently employed in building frameworks, including high-rise structures and bridges. Its ability to carry heavy loads while minimizing the amount of material used makes it an efficient choice.

2. Fencing and Railings Thanks to its aesthetic appeal, CHS is often used in fencing and railing systems. The smooth surface allows for effective protection while also providing a modern look.

steel chs sizes

3. Industrial Structures In warehouses and manufacturing plants, CHS is used for support beams and columns. Its resistance to corrosion and environmental wear makes it particularly suitable for these settings.

4. Prefab Construction With the rise of modular and prefabricated construction, CHS serves as a foundational material due to its lightweight nature and ease of assembly.

5. Marine Applications The maritime industry often relies on CHS for piers, docks, and other structures exposed to harsh conditions. The tubular shape minimizes drag and enhances durability.

Benefits of Using Steel CHS

The preference for CHS over other types of structural sections can be attributed to several advantages

- Weight Efficiency The hollow design reduces the overall weight of the structure without compromising strength, allowing for simpler logistics and transportation.

- Aesthetic Versatility CHS can be easily integrated into various architectural designs, providing a sleek and modern look.

- Ease of Fabrication CHS can be cut, welded, and manipulated in various ways to meet specific project requirements, enhancing construction efficiency.

- Sustainability Steel is a recyclable material, making CHS a sustainable choice for eco-conscious projects.

Conclusion

As demand for innovative and efficient construction methods rises, understanding the intricacies of materials such as Steel CHS becomes ever more pertinent. With its range of sizes and multitude of applications, CHS not only fulfills the structural requirements of projects but also aligns with contemporary design aesthetics. Engineers, architects, and construction professionals must utilize the full potential of steel CHS to create safe, sustainable, and visually appealing structures in an evolving industry.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

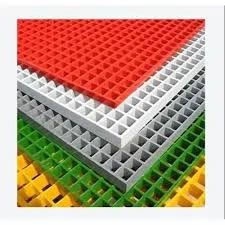

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025