loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Features and Benefits of Starlite FRP Tanks for Various Applications

Understanding the Starlite FRP Vessel A Revolution in Composite Technology

In recent years, the engineering and manufacturing sectors have witnessed significant advancements in materials science, leading to the development of innovative solutions that optimize performance, durability, and sustainability. One such remarkable innovation is the Starlite FRP (Fiberglass Reinforced Plastic) vessel, a cutting-edge composite structure that combines the best properties of fiberglass with modern engineering techniques. This article explores the features, advantages, and applications of Starlite FRP vessels, highlighting why they have become increasingly popular across various industries.

What are Starlite FRP Vessels?

Starlite FRP vessels are specialized containers constructed from fiberglass reinforced plastics, designed to store and transport various substances, including chemicals, water, and other fluids. The composite material consists of a polymer matrix reinforced with glass fibers, which provide exceptional strength and corrosion resistance. This unique combination allows Starlite FRP vessels to withstand harsh operating conditions and environmental factors that would typically degrade traditional materials such as steel or aluminum.

Key Features of Starlite FRP Vessels

1. Corrosion Resistance One of the most significant advantages of Starlite FRP vessels is their exceptional resistance to corrosion. Unlike metal containers, which can corrode over time due to exposure to chemicals and moisture, FRP vessels maintain their structural integrity, ensuring a longer lifespan and reduced maintenance costs.

2. Lightweight The lightweight nature of fiberglass composites makes Starlite FRP vessels easy to handle, transport, and install. This characteristic not only reduces labor costs but also allows for easier integration into existing systems, especially in industries where weight is a crucial factor.

3. Customization Starlite FRP vessels can be tailored to meet specific requirements, including size, shape, and chemical compatibility. This flexibility allows manufacturers to produce vessels that cater to the unique needs of different industries, enhancing efficiency and operational effectiveness.

4. Thermal Insulation The composition of FRP materials provides excellent thermal insulation, making Starlite FRP vessels ideal for applications that require temperature control or protection from extreme temperatures. This feature is particularly beneficial in the food and beverage industry, where maintaining specific temperatures is essential for product quality.

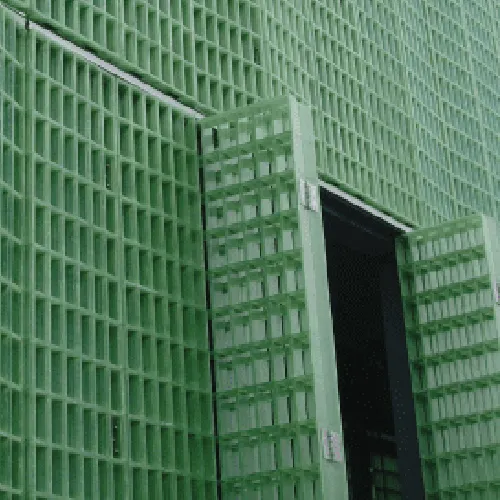

starlite frp vessel

5. Environmental Sustainability As the world shifts towards more sustainable practices, Starlite FRP vessels stand out as an eco-friendly option. Their durability reduces the frequency of replacements, and many FRP materials can be recycled, contributing to a circular economy.

Applications of Starlite FRP Vessels

The versatility of Starlite FRP vessels allows them to be utilized across a wide range of industries. Some notable applications include

- Chemical Storage Starlite FRP vessels are commonly used in the chemical industry for storing aggressive chemicals and solvents. Their corrosion resistance ensures safe and secure containment, minimizing the risk of leaks and contamination.

- Water Treatment In municipal and industrial water treatment facilities, these vessels are used for storing and processing water, chemicals, and biological materials. Their lightweight design makes them easier to incorporate into existing treatment systems.

- Oil and Gas The oil and gas industry relies on Starlite FRP vessels for the storage and transport of crude oil, natural gas, and various petroleum products. Their ability to withstand high pressures and harsh environments makes them ideal for this sector.

- Food and Beverage In the food industry, Starlite FRP vessels are used for the storage and processing of liquids such as juices, oils, and dairy products. Their non-reactive properties ensure that the quality and safety of the food products are maintained.

Conclusion

The Starlite FRP vessel exemplifies the evolution of materials in engineering and manufacturing, offering a host of benefits that traditional materials struggle to match. Its durability, lightweight nature, customization options, and environmental sustainability make it a preferred choice across various industries. As technology continues to advance, the applications and capabilities of Starlite FRP vessels are likely to expand further, solidifying their role as a cornerstone in modern engineering solutions. Whether for chemical storage, water treatment, or food processing, Starlite FRP vessels are undoubtedly paving the way for a more efficient and sustainable future.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025